Abstract

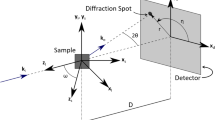

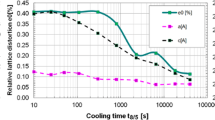

Advanced High-Strength Steels make use of retained austenite to improve mechanical properties. The benefits of the austenitic phase are directly tied to the phase fraction present in a material. However, phase characterization of retained austenite is complicated by the often metastable nature of the phase and the presence of crystallographic texture in many steel products. Diffraction-based measurements of retained austenite in particular exhibit large texture bias errors in the measurement of sheet steels. The wide availability of low-energy X-ray diffraction equipment, however, makes the method attractive for relatively rapid characterization of materials. Reducing texture bias error for X-ray measurements of retained austenite, therefore, may benefit both industry and research. A method of reducing the texture bias error using a hexagonal grid-sampling scheme has been investigated via simulations and validated experimentally. The sampling scheme consists of measuring the sample at multiple diffraction vectors of roughly even spacing on the pole figure. The diffraction vectors, which define the crystal orientations that can contribute to each measurement, are arranged in a hexagonal pattern. The hexagonal pattern averages the texture bias present at multiple orientations, and thus, reduces the overall texture bias error in the calculated retained austenite phase fraction. Simulation and experimental results agreed closely, particularly for the commonly performed normal-direction measurement. The 30 deg hex scheme simulations and experimental measurement exhibited greatly reduced texture bias error.

Similar content being viewed by others

Notes

Certain commercial entities, equipment, or materials may be identified in this document to describe an experimental procedure or concept adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the entities, materials, or equipment are necessarily the best available for the purpose.

References

K. Hickey: Defining Steels - AHSS Guidelines, https://ahssinsights.org/metallurgy/defining-steels/, (accessed 12 October 2021).

R. Kuziak, R. Kawalla, and S. Waengler: Arch. Civ. Mech. Eng., 2008, vol. 8, pp. 103–17.

D.K. Matlock and J.G. Speer: in Microstructure and Texture in Steels, A. Haldar, S. Suwas, and D. Bhattacharjee, eds., Springer, London, 2009, pp. 185–205.

P.J. Jacques, S. Allain, O. Bouaziz, A. De, A.-F. Gourgues, B.M. Hance, Y. Houbaert, J. Huang, A. Iza-Mendia, S.E. Kruger, M. Radu, L. Samek, J. Speer, L. Zhao, and S. van der Zwaag: Mater. Sci. Technol., 2009, vol. 25, pp. 567–74.

L. Zhao, N.H. van Dijk, E. Brück, J. Sietsma, and S. van der Zwaag: Mater. Sci. Eng. A, 2001, vol. 313, pp. 145–52.

A. Creuziger, C.A. Calhoun, W.A. Poling, and T. Gnäupel-Herold: J. Appl. Crystallogr., 2018, vol. 51, pp. 720–31.

C.F. Jatczak, J.A. Larson, and S.W. Shin: Retained Austenite and Its Measurements by X-Ray Diffraction: An Information Manual, Society of Automotive Engineers, Warrendale, PA, 1980.

B.D. Cullity: Elements of X-Ray Diffraction, 2d ed. Addison-Wesley Pub. Co, Reading, MA, 1978.

L. Lutterotti, D. Chateigner, S. Ferrari, and J. Ricote: Thin Solid Films, 2004, vol. 450, pp. 34–41.

B.H. Toby and R.B. Von Dreele: J. Appl. Crystallogr., 2013, vol. 46, pp. 544–49.

M.J. Dickson: J. Appl. Crystallogr., 1969, vol. 2, pp. 176–80.

A. Creuziger, C.A. Calhoun, W.A. Poling, and T. Gnäupel-Herold: Data Set: Assessment of Bias Errors Caused by Texture and Sampling Methods in Diffraction-Based Steel Phase Measurements, https://github.com/usnistgov/Texture-Sampling-PhaseMeasurement-BiasErrors.

R. Miller: ASM Trans. Q., 1968, vol. 61, pp. 592–97.

A. Creuziger, T. Phan, and D. Pagan: J. Appl. Crystallogr., 2021, vol. 54, pp. 1480–89.

U. Kocks, C. Tome, and H.-R. Wenk: Texture and Anisotropy: Preferred Orientations in Polycrystals and Their Effect on Materials Properties, 2nd ed. Cambridge University Press, Cambridge, 1998.

P. Brand, H. Prask, and T. Gnaeupel-Herold: Physica B, 1997, vol. 241, pp. 1244–45.

T. Gnäupel-Herold and A. Creuziger: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3594–3600.

S. Matthies and H.R. Wenk: Phys. Status Solidi A, 1992, vol. 133, pp. 253–57.

E04 Committee: Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. ASTM International.

L. Barrales-Mora, Y. Lü, and D. Molodov: Steel Res. Int., 2011, vol. 82, pp. 119–26.

D. De Knijf, R. Petrov, C. Föjer, and L.A.I. Kestens: Mater. Sci. Eng. A, 2014, vol. 615, pp. 107–15.

M. De Meyer, L. Kestens, and B. De Cooman: Mater. Sci. Technol., 2001, vol. 17, pp. 1353–59.

J. Capek, M. Cernik, N. Ganev, K. Trojan, J. Nemecek, and K. Kolarik: IOP Conf. Ser. Mater. Sci. Eng., 2018, vol. 375, p. 012025.

L.A.I. Kestens and H. Pirgazi: Mater. Sci. Technol., 2016, vol. 32, pp. 1303–15.

A.C. Rizzie, T.R. Watkins, and E.A. Payzant: Powder Diffr., 2008, vol. 23, pp. 87–91.

M. Cox III: Reducing the Effects of Texture on Phase Fraction Measurement of Retained Austenite Using X-Ray Diffraction MT-SRC-021-016, Colorado School of Mines, Advanced Steel Processing and Products Research Center, 2021.

B. Ennis: A Review of the Effects of Chemical and Phase Segregation on the Mechanical Behaviour of Multi-Phase Steels, arXiv, 2016.

G.F. Vander Voort: Metallography, Principles and Practice, ASM International, 1999.

A. Clarke: Colorado School of Mines, 2006.

M. Thrun: Retained Austenite Calculator for X-Ray Diffraction, 2018.

M.R. Cox III and A. Creuziger: Phase Measurement Data Publication. https://github.com/MikeCox3/PhaseMeasurement-DataPublication.

H.P. Klug and L.E. Alexander: X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed. Wiley, New York, 1974.

Acknowledgments

The authors wish to thank: industrial mentors Matt Merwin and Brian Lin; Whitney Poling and Thomas Gnaupel-Herold for providing neutron diffraction measurements; sponsors, staff, and students at the Advanced Steel Processing and Products Research Center (ASPPRC) at the Colorado School of Mines for their advice and assistance; members of the NIST Center for Automotive Lightweighting for their advice and assistance; K.S. Raghavan, Ming Shi, and the Auto/Steel Partnership for supplying the experimental material; and Surya Chandramouleeswaran for performing simulation work which greatly furthered insight into the robustness of the sampling schemes. This work was supported by the National Institute of Standards and Technology (NIST), part of the United States Department of Commerce.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cox, M.R., Creuziger, A. & Findley, K.O. A Hexagonal Grid-Sampling Scheme for Improving X-Ray Diffraction-Retained Austenite Measurements of Sheet Steels. Metall Mater Trans A 54, 823–837 (2023). https://doi.org/10.1007/s11661-022-06931-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06931-8