Abstract

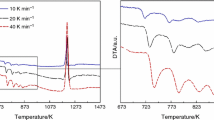

The impact of pre-annealing temperature on the crystallization and nitridation of amorphous will be investigated. Sm2Fe17ZrNb0.4Cu0.2B0.2 amorphous alloy ribbons were prepared by melt spinning at the speed of 40 m/s, and the ribbons were two-step annealed after nitridation. The phase composition and microstructure of the material were characterized, glass-forming ability (GFA) was analyzed and the nitrogen content of ribbons were detected. The results indicate that pre-annealing treatment is effective in inhibiting the rapid precipitation of the α-Fe phase. The equiaxed grains with uniform size were obtained by two-step annealed, of which the pre-annealing treatment is at 773 K for 90 minutes and crystallization treatment is at 873 K for 10 minutes. The initial crystallization temperature is reduced from 908 K to 793 K. The nitrogen content is ~ 2.68 pct after two-step annealing, which increases ~ 5.6 pct than that of the direct crystallization (~ 2.53 pct). Therefore, pre-annealing treatment at 773 K for 90 minutes can achieve microstructural reconstruction of Sm2Fe17ZrNb0.4Cu0.2B0.2, the reduced crystallization temperature inhibits the overflow of nitrogen atoms and improves the nitriding efficiency.

Similar content being viewed by others

References

R.Q. Ma, S.J. Li, Q.M. Zhou, and Z.M. Li: Proc. CSEE, 1998, vol. 18, pp. 27–31.

M.J. Li, S.L. Wang, and F.H. Cui: Anal. Lab., 2006, vol. 12, pp. 81–83.

J.H. Zhu: J. Electrotech. Sci., 1988, vol. 1, pp. 13–17.

J.H. Yi and Y.D. Peng: Rare Met. Mater. Eng., 2004, vol. 4, pp. 337–42.

H. Nakamura: Scripta Mater., 2018, vol. 154, pp. 273–76.

A. Trench and J.P. Sykes: Engineering, 2020, vol. 6, pp. 34–41.

S.M. Pang, D.H. Chen, Z.A. Li, S.H. Yan, L. Zhou, L.H. Xu, Z.Q. Wang, and J.L. Xu: Chin. J. Rare Earths, 2013, vol. 31, pp. 14–19.

M. Xiao: Jiangxi Chem. Ind., 2018, vol. 6, pp. 242–43.

K.X. Zhang, K. Liu, and Z.P. Yuan: Mater. Sci., 2020, vol. 10, pp. 506–11.

Y.M. Yang: China Powder Ind., 2020, vol. 2, pp. 27–30.

Y.K. Zhang, S.H. Wang, Y.L. Feng, and K. Liu: Rare Met. Cem Carbide, 2020, vol. 48(02), pp. 41–46.

C.X. Cui, J.M. Li, J.B. Sun, and R.P. Han: Funct. Mater., 2004, vol. 1, pp. 31–33.

M. Wu: Min. Lett., 2000, vol. 10, pp. 4–5.

P. Sun and C. Guo: Mod. Manuf. Technol. Equip., 2020, vol. 56, pp. 115–16.

W. Klement, R. Jun, H. Willens, and P. Duwez: Nature, 1960, vol. 4740, pp. 869–70.

Y. Yang, J.H. Hu, L.F. Wang, Q. Wu, P.Y. Zhang, and H.L. Ge: Magn. Mater. Dev., 2015, vol. 5, pp. 64–69.

Z.W. Liu, J.Y. He, and R.V. Ramanujan: Mater. Des., 2021, vol. 209, pp. 110004–12.

T.H. Wang, Y.Q. Qin, X.Q. Huang, Q. Zhang, and H. Xu: Hot Process. Technol., 2017, vol. 14, pp. 45–47.

G.W. Wang, F.F. Shao, and W.G. Wei: Heat Treat. Technol. Equip., 2011, vol. 3, pp. 30–33.

Z.F. Wu, J. Wu, L. Zhang, R. Wu, and Q.M. Chang: Rare Metal Mater. Eng., 2018, vol. 7, pp. 1993–98.

K. Lu: Acta Metall. Sin., 1990, vol. 5, pp. 92–96.

P.Y. Zhang, J.W. Zhang, J.H. Liu, L. Yang, K.Q. Zhang, Y. Guan, and X.Y. Zhang: J. Funct. Mater. Dev., 2001, vol. 7, pp. 423–26.

M. Matsuura, K. Yamamoto, S. Sugimoto, N. Sakuma, and M. Ito: Mater. Trans., 2022, vol. 63, pp. 363–72.

C.Z. Hu, Z. Guo, S. Wu, Z. Sun, C.C. Li, L.J. Liu, and L. Fang: Ceram. Int., 2018, vol. 44, pp. 224–27.

P.Y. Zhang, J.W. Zhang, J.H. Liu, L. Yang, K.Q. Zhang, Y. Guan, and X.Y. Zhang: J. Funct. Mater. Dev., 2001, vol. 4, pp. 423–26.

G. Yu and K. Lücke: Prog. Nat. Sci., 1995, vol. 3, pp. 81–88.

X.L. Wang and X. Yao: J. Silic., 1994, vol. 22, pp. 381–86.

Y.Z. Zhang and H.J. Jin: Acta Metall. Sin., 1984, vol. 2, pp. 85–88.

S. Guo and C.T. Liu: Prog. Nat. Sci, 2011, vol. 21, pp. 433–46.

L.X. Shi and K.F. Yao: Mater. Des., 2020, vol. 189, p. 108511.

U. Andrey, M. Viktoria, and V. Aleksey: J. Magn. Magn. Mater., 2022, vol. 551, pp. 169143–45.

Acknowledgments

This work was supported by Colleges and Universities in Hebei Province Science and Technology Research Project (No. QN2021115), Natural Science Foundation of Hebei Province (No. E2021209146) and The Central Government Guides the Local Science and Technology Development Fund Project (Free Exploration Basic Research No. 226Z1006G). We would like to thank Editage (www.editage.cn) for English language editing.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Wang, S., Liu, K. et al. Regulating the Microstructure of Sm2Fe17ZrNb0.4Cu0.2B0.2 Amorphous Alloys by Two-Step Annealed. Metall Mater Trans A 54, 605–614 (2023). https://doi.org/10.1007/s11661-022-06905-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06905-w