Abstract

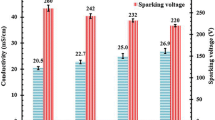

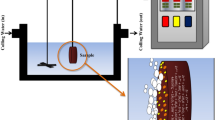

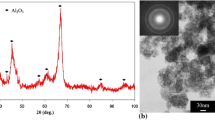

Plasma electrolytic oxidation (PEO) is a common surface treatment method to improve the properties of titanium alloys. Here, the structure, composition and corrosion resistance of the PEO coating treated in silicate electrolyte was investigated to uncover the effect of cathode current on PEO and how softening sparks work using bipolar mode (soft sparking mode), scanning electron microscope, X-ray energy dispersive spectrometer, transmission electron microscope, X-ray diffraction and potentiodynamic polarization test. The results show that the cathode current can reduce the spark intensity, promote the spark to migrate to the inner coating, resulting in a dense and thick inner layer. Besides, the cathode current can promote the type-A discharge, thus forming bubble-like oxide protrusions and bowl-like pits on the coating surface. The formation of TiO2 is inhibited with the cathode current increasing, so the thickness of the coating and the amorphous layer at the coating/substrate interface decreases. The spark causes SiO32− to form amorphous SiO2 which deposits around the pores. The existence of filamentous discharge in the inner layer was confirmed by observing SiO2 deposition location. After spark softening, coating growth is achieved by forming amorphous TiO2, but softening sparks can promote the transformation of amorphous TiO2 into rutile and anatase around them. The increasing cathode current increases the amount of electrolyte ions deposited in the outer layer, which provides a new method for functional coating prepared by using particle deposition.

Similar content being viewed by others

References

L. Wang, W. Fu, G. Yi, Z. Chen, Z. Gao, and Q. Pan: Membranes, 2022, vol. 12, p. 516. https://doi.org/10.3390/membranes12050516.

V. Grebnevs, K. Lesniak-Ziolkowska, M. Wala, M. Dulski, S. Altundal, A. Dutovs, L. Avotina, D. Erts, R. Viter, A. Viksna, and W. Simka: Appl. Surf. Sci., 2022, vol. 598, 153793. https://doi.org/10.1016/j.apsusc.2022.153793.

M. Adigamova, I. Lukiyanchuk, I. Tkachenko, and V. Morozova: Mater. Chem. Phys., 2022, vol. 275, 125231https://doi.org/10.1016/j.matchemphys.2021.125231.

C. Yang, S. Cui, Z. Wu, J. Zhu, J. Huang, Z. Ma, R. Fu, X. Tian, P. Chu, and Z. Wu: Tribol. Int., 2021, vol. 160, 107018. https://doi.org/10.1016/j.triboint.2021.107018.

X. Zhang, G. Cai, Y. Lv, Y. Wu, and Z. Dong: Surf. Coat. Technol., 2020, vol. 400, 126202. https://doi.org/10.1016/j.surfcoat.2020.126202.

T. Narayanan, J. Kim, and H. Park: Appl. Surf. Sci., 2020, vol. 504, 144388. https://doi.org/10.1016/j.apsusc.2019.144388.

M. Becerikli, A. Kopp, N. Kroger, M. Bodrova, C. Wallner, J. Wagner, M. Dadras, B. Jettkant, F. Pohl, M. Lehnhardt, O. Jung, and B. Behr: Mater. Sci. Eng. C-Mater. Biol. Appl., 2021, vol. 123, 112030. https://doi.org/10.1016/j.msec.2021.112030.

D. Mashtalyar, K. Nadaraia, I. Imshinetskiy, E. Belov, V. Filonina, S. Suchkov, S. Sinebryukhov, and S. Gnedenkov: Appl. Surf. Sci., 2021, vol. 536, 147976. https://doi.org/10.1016/j.apsusc.2020.147976.

M. Martinez-Viademonte, S. Abrahami, T. Hack, M. Burchardt, and H. Terryn: Coatings, 2020, vol. 10, p. 1106. https://doi.org/10.3390/coatings10111106.

D. Zhai, K. Feng, and H. Yue: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2019, vol. 50A, pp. 2507–18. https://doi.org/10.1007/s11661-019-05185-1.

M. Molaei, M. Nouri, K. Babaei, and A. Fattah-Alhosseini: Surf. Interfaces, 2021, vol. 22, 100888. https://doi.org/10.1016/j.surfin.2020.100888.

A. Bu, Y. Zhang, Y. Xiang, W. Chen, H. Cheng, and L. Wang: J. Mater. Sci. Mater. Electron., 2020, vol. 31, pp. 17067–74. https://doi.org/10.1007/s10854-020-04264-z.

M. Nadimi and C. Dehghanian: Ceram. Int., 2021, vol. 47, pp. 33413–25. https://doi.org/10.1016/j.ceramint.2021.08.248.

N. Ao, D. Liu, X. Zhang, and G. He: J. Alloys Compd., 2020, vol. 823, 153823. https://doi.org/10.1016/j.jallcom.2020.153823.

A. Bordbar-Khiabani, S. Ebrahimi, and B. Yarmand: Corros. Sci., 2020, vol. 173, 108781. https://doi.org/10.1016/j.corsci.2020.108781.

D.S. Tsai and C.C. Chou: Metals, 2018, vol. 8, p. 105. https://doi.org/10.3390/met8020105.

D.S. Tsai, G.W. Chen, and C.C. Chou: Surf. Coat. Technol., 2019, vol. 357, pp. 235–43. https://doi.org/10.1016/j.surfcoat.2018.09.080.

M. Shao, W. Wang, H. Yang, X. Zhang, and X. He: Coatings, 2021, vol. 11, p. 1288. https://doi.org/10.3390/coatings11111288.

A.B. Rogov, A. Yerokhin, and A. Matthews: Langmuir, 2017, vol. 33, pp. 11059–69. https://doi.org/10.1021/acs.langmuir.7b02284.

R. Hussein, P. Zhang, X. Nie, Y. Xia, and D. Northwood: Surf. Coat. Technol., 2011, vol. 206, pp. 1990–97. https://doi.org/10.1016/j.surfcoat.2011.08.060.

M. Rahmati, K. Raeissi, M. Toroghinejad, A. Hakimizad, and M. Santamaria: Coatings, 2019, vol. 9, p. 688. https://doi.org/10.3390/coatings9100688.

Z. Yao, Y. Jiang, F. Jia, Z. Jiang, and F. Wang: Appl. Surf. Sci., 2008, vol. 254, pp. 4084–91. https://doi.org/10.1016/j.apsusc.2007.12.062.

Z. Yao, Y. Liu, Y. Xu, Z. Jiang, and F. Wang: Mater. Chem. Phys., 2011, vol. 126, pp. 227–31. https://doi.org/10.1016/j.matchemphys.2010.11.035.

R.O. Hussein, X. Nie, and D.O. Northwood: Mater. Chem. Phys., 2012, vol. 134, pp. 484–92. https://doi.org/10.1016/j.matchemphys.2012.03.020.

S. Aliasghari, P. Skeldon, and G.E. Thompson: Appl. Surf. Sci., 2014, vol. 316, pp. 463–76. https://doi.org/10.1016/j.apsusc.2014.08.037.

W. Gebarowski and S. Pietrzyk: Arch. Metall. Mater., 2014, vol. 59, pp. 407–11. https://doi.org/10.2478/amm-2014-0070.

M. Laveissiere, H. Cerda, J. Roche, L. Cassayre, and L. Arurault: Surf. Coat. Technol., 2019, vol. 361, pp. 50–62. https://doi.org/10.1016/j.surfcoat.2018.12.122.

J. Han, Y. Cheng, W. Tu, T. Zhan, and Y. Cheng: Appl. Surf. Sci., 2018, vol. 428, pp. 684–97. https://doi.org/10.1016/j.apsusc.2017.09.109.

W. Cui, L. Jin, and L. Zhou: Mater. Sci. Eng. C Mater. Biol. Appl., 2013, vol. 33, pp. 3775–79. https://doi.org/10.1016/j.msec.2013.05.011.

T. Teh, A. Berkani, S. Mato, P. Skeldon, G.E. Thompson, H. Habazaki, and K. Shimizu: Corros. Sci., 2003, vol. 45, pp. 2757–68. https://doi.org/10.1016/S0010-938X(03)00101-X.

A. Hakimizad, K. Raeissi, M. Santamaria, and M. Asghari: Electrochim. Acta, 2018, vol. 284, pp. 618–29. https://doi.org/10.1016/j.electacta.2018.07.200.

R. Hussein, X. Nie, D. Northwood, A. Yerokhin, and A. Matthews: J. Phys. D-Appl. Phys., 2010, vol. 43, 105203. https://doi.org/10.1088/0022-3727/43/10/105203.

Q. Li, W. Yang, C. Liu, D. Wang, and J. Liang: Surf. Coat. Technol., 2017, vol. 316, pp. 162–70. https://doi.org/10.1016/j.surfcoat.2017.03.021.

H.B. Wang, D. Zhai, and K. Feng: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2021, vol. 52, pp. 4691–702. https://doi.org/10.1007/s11661-021-06421-3.

S. Tsunekawa, Y. Aoki, and H. Habazaki: Surf. Coat. Technol., 2011, vol. 205, pp. 4732–40. https://doi.org/10.1016/j.surfcoat.2011.04.060.

A. Lugovskoy and S. Lugovskoy: Mater. Sci. Eng. C Mater., 2014, vol. 43, pp. 527–32. https://doi.org/10.1016/j.msec.2014.07.030.

E. Poorqasemi, O. Abootalebi, M. Peikari, and F. Haqdar: Corros. Sci., 2009, vol. 51, pp. 1043–54. https://doi.org/10.1016/j.corsci.2009.03.001.

M. Chiku, W. Tsujiwaki, E. Higuchi, and H. Inoue: J. Power Sources, 2013, vol. 244, pp. 675–78. https://doi.org/10.1016/j.jpowsour.2012.12.047.

J. Bockris: J. Chem. Phys., 1956, vol. 24, pp. 817–27. https://doi.org/10.1063/1.1742616.

X. Wang, S. Hu, W. Li, and Y. Hu: Constr. Build. Mater., 2022, vol. 337, 127572. https://doi.org/10.1016/j.conbuildmat.2022.127572.

Q. Tang, T. Qiu, P. Ni, D. Zhai, and J. Shen: Coatings, 2022, vol. 12, p. 1191. https://doi.org/10.3390/coatings12081191.

H. Chen, J. Shen, J. Deng, Y. Hu, and Y. Zhang: Appl. Surf. Sci., 2020, vol. 508, 145285. https://doi.org/10.1016/j.apsusc.2020.145285.

A. Pergament, A. Velichko, V. Putrolaynen, G. Stefanovich, N. Kuldin, A. Cheremisin, I. Feklistov, and N. Khomlyuk: J. Phys. D Appl. Phys., 2008, vol. 41, p. 225306. https://doi.org/10.1088/0022-3727/41/22/225306.

R.S. Alwitt: J. Electrochem. Soc., 1987, vol. 134, pp. 1891–96. https://doi.org/10.1149/1.2100784.Author.

Acknowledgments

This research is funded by China Postdoctoral Science Foundation (Grant No.2021M700569), Chongqing Postdoctoral Science Foundation (Grant No. cstc2021jcyj-bsh0133), and 2022 Jiangsu Provincial Science and technology plan special fund BE2022110 (key research and development plan, industry prospect and key core technology).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author Contributions

TQ: Writing, analyzing, investigation and drawing. LT: Editing, investigation and formal analysis. DZ: Experiment and theoretical analysis. PN: Formal analysis, Investigation, Data Curation. JS: Editing and writing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiu, T., Tan, L., Zhai, D. et al. Correlation Between Plasma Electrolytic Oxidation Coating on Ti6Al4V Alloy and Cathode Current. Metall Mater Trans A 54, 333–345 (2023). https://doi.org/10.1007/s11661-022-06883-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06883-z