Abstract

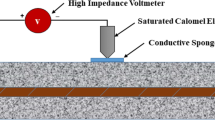

In this article, the rusting evolution of 690 MPa grade multifunctional construction structural steel was investigated under a simulated industrial atmospheric environment. The corrosion product stabilization process was examined using the corrosion mass loss method, electrochemical measurements, X-ray diffraction (XRD), scanning electron microscopy (SEM), and electron probe microanalysis (EPMA). The results indicated that the corrosion kinetics exhibited a two-stage process, including a rapid stage followed by a slow stage. The initial sharp rise in corrosion rate was related to the involvement of reducible corrosion products in the cathode reduction process, which accelerated the dissolution of the anodic steel substrate. The appearance of the inflection point in the corrosion stage was strongly associated with the accumulation of corrosion products. As the corrosion time progressed, the corrosion products changed from porous to compact structures because of the synergistic effects of Cu, Ni, and Cr. This compact, thick, and uniform rust layer was identified to contain aggregates of crystalline γ-FeOOH along with a large number of fully grown flowery-shaped α-FeOOH on its top. Thus, the corrosion resistance increased when the rust layer gradually accumulated, and the diffusion of the corrosive ions was obstructed owing to the inhibited electrochemical corrosion. After a prolonged dry–wet cyclic corrosion, the rust layer led to stress cracking, but its self-repairing ability would make the cracks die.

Similar content being viewed by others

References

T.Y. Zhang, W. Liu, Z. Yin, B.J. Dong, Y.G. Zhao, Y.M. Fan, J.S. Wu, Z. Zhang, and X.G. Li: J. Mater. Eng. Perform., 2020, vol. 29, pp. 2531–41.

S. Sabir and A.A. Ibrahim: Corros. Eng. Sci. Technol., 2017, vol. 52, pp. 276–82.

W. Wu, X.Q. Cheng, J.B. Zhao, and X.G. Li: Corros. Sci., 2020, vol. 165, 108416.

Z.Y. Liu, M. Zhao, X.L. Wang, and J.G. Li: J. B. Univ. Chem. Technol. (Nat. Sci. Ed.), 2016, vol. 43, pp. 57–62.

Z.Y. Chen, Z.G. Lin, J.J. Qi, Y. Feng, L.Q. Chen, and G.D. Wang: Acta Metall. Sin. Engl. Lett., 2022, https://doi.org/10.1007/s40195-021-01359-2.

W.M. Liu, J. Liu, H.B. Pan, F.B. Cao, Z.J. Wu, H.H. Lv, and Z.Y. Xu: J. Alloys Compd., 2020, vol. 834, 155095.

W. Wu, Z.Y. Liu, X.G. Li, C.W. Du, and Z.Y. Cui: Mater. Sci. Eng. A, 2019, vol. 759, pp. 124–41.

W. Wu, Z.Y. Liu, Q.Y. Wang, and X.G. Li: Corros. Sci., 2020, vol. 170, 108693.

C. Pan, W. Han, Z.Y. Wang, C. Wang, and G.C. Yu: J. Mater. Eng. Perform., 2016, vol. 25, pp. 5382–90.

T.L. Zhao, K. Liu, and Q. Li: Constr. Build. Mater., 2021, vol. 309, 125211.

W.T. Zhu, J.J. Cui, Z.Y. Chen, Y. Feng, Y. Zhao, and L.Q. Chen: Acta Metall. Sin., 2021, vol. 57, pp. 340–52.

W.T. Zhu, J.J. Cui, Z.Y. Chen, Y. Zhao, and L.Q. Chen: Acta Metall. Sin. Engl. Lett., 2022, vol. 35, pp. 527–36.

J.X. Yu, H.K. Wang, Y. Yu, Z. Luo, W.D. Liu, and C.M. Wang: Corros. Sci., 2018, vol. 133, pp. 276–87.

R. Vera, R. Araya, C. Garín, S. Ossandón, and P. Rojas: Mater. Corros., 2019, vol. 70, pp. 1151–61.

C. Martínez, F. Briones, M. Villarroel, and R. Vera: Materials, 2018, vol. 11, pp. 591–607.

M. Yamashita, H. Konishi, T. Kozakura, J. Mizuki, and H. Uchida: Corros. Sci., 2005, vol. 47, pp. 2492–98.

J. Alcántara, B. Chico, J. Simancas, I. Díaz, D. de la Fuente, and M. Morcillo: Mater. Charact., 2016, vol. 118, pp. 65–78.

H. Chen, H.Y. Cui, Z.B. He, L. Lu, and Y.H. Huang: Mater. Chem. Phys., 2021, vol. 259, 123971.

Y. Zhang, F. Huang, Q. Hu, Z.X. Peng, and J. Liu: Mater. Chem. Phys., 2020, vol. 241, 122045.

S. Fonna, I.B.M. Ibrahim, Gunawarman, S. Huzni, M. Ikhsan, and S. Thalib: Heliyon, 2021, vol. 7, p. e06608.

R.E. Melchers: Corros. Sci., 2013, vol. 68, pp. 186–94.

J.F. Gu, Y. Xiao, N.W. Dai, X. Zhang, Q.Z. Ni, and J.X. Zhang: Corros. Eng. Sci. Techn., 2019, vol. 54, pp. 249–56.

H.Y. Wu, H.G. Lei, Y.F. Chen, and J.Y. Qiao: Constr. Build. Mater., 2019, vol. 211, pp. 228–43.

J.D. Fu, S. Wan, Y. Yang, Q. Su, W.W. Han, and Y.B. Zhu: Constr. Build. Mater., 2021, vol. 306, 124864.

N.S. Palsson, K. Wongpinkaew, P. Khamsuk, S. Sorachot, and W. Pongsaksawad: Mater. Corros., 2019, vol. 71, pp. 1019–34.

P. Cheng, J. Liu, X.Q. Huang, F. Huang, and T. Pang: Constr. Build. Mater., 2022, vol. 328, 127030.

D. de la Fuente, I. Díaz, J. Simancas, B. Chico, and M. Morcillo: Corros. Sci., 2011, vol. 53, pp. 604–17.

Q. Guo, Y. Zhao, Y. Xing, J.F. Jiao, B.Z. Fu, and Y.Q. Wang: Structures, 2022, vol. 39, pp. 115–31.

Y.H. Qian, C.H. Ma, D. Niu, J.J. Xu, and M.S. Li: Corros. Sci., 2013, vol. 74, pp. 424–29.

K. Wei and J.H. Dong: Acta Metall. Sin., 2010, vol. 46, pp. 1365–78.

M.E. Ikpi and B.O. Okonkwo: J. Mater. Environ. Sci., 2017, vol. 8, pp. 3809–16.

C. Thee, L. Hao, J.H. Dong, X. Mu, X. Wei, X.F. Li, and W. Ke: Corros. Sci., 2014, vol. 78, pp. 130–37.

T.Y. Zhang, W. Liu, T. Chowwanonthapunya, B.J. Dong, Y.G. Zhao, and Y.M. Yang: J. Mater. Eng. Perform., 2020, vol. 29, pp. 5057–68.

B. Qian, B.R. Hou, and M. Zheng: Corros. Sci., 2013, vol. 72, pp. 1–9.

M. Hosseini, S.F.L. Mertens, M. Ghorbani, and M.R. Arshadi: Mater. Chem. Phys., 2003, vol. 78, pp. 800–08.

H.Q. Fan, S.Y. Li, Z.C. Zhao, H. Wang, Z.C. Shi, and L. Zhang: Corros. Sci., 2011, vol. 53, pp. 4273–81.

M. Cao, L. Liu, Z.F. Yu, L. Fan, Y. Li, and F.H. Wang: J. Mater. Sci. Technol., 2019, vol. 35, pp. 651–59.

Y.Y. Chen, H.J. Tzeng, L.I. Wei, L.H. Wang, J.C. Oung, and H.C. Shih: Corros. Sci., 2005, vol. 47, pp. 1001–21.

Y.L. Zhou, J. Chen, and Z.Y. Liu: J. Iron Steel Res. Int., 2013, vol. 20, pp. 66–73.

E. Zitrou, J. Nikolaou, P.E. Tsakiridis, and G.D. Papadimitriou: Constr. Build. Mater., 2007, vol. 21, pp. 1161–69.

R.R. Hussain, A. Al-Negheimish, A. Alhozaimy, and D.D.N. Singh: Cem. Concr. Compos., 2020, vol. 113, 103728.

W.J. Chen, L. Hao, J.H. Dong, and W. Ke: Corros. Sci., 2014, vol. 83, pp. 155–63.

C. Lin, Q. Zhao, Y.E. Liu, and J.N. Liang: Acta Metall. Sin., 2010, vol. 46, pp. 358–65.

M. Kimura, H. Kihira, N. Ohta, M. Hashimoto, and T. Senuma: Corros. Sci., 2005, vol. 47, pp. 2499–2509.

M. Stratmann, K. Bohnenkamp, and H.J. Engell: Corros. Sci., 1983, vol. 23, pp. 969–85.

T. Kamimura, S. Hara, H. Miyuki, M. Yamashita, and H. Uchida: Corros. Sci., 2006, vol. 48, pp. 2799–2812.

M. Yamashita, H. Miyuki, Y. Matsuda, H. Nagano, and T. Misawa: Corros. Sci., 1994, vol. 25, pp. 283–99.

C. Pan, M.X. Guo, W. Han, Z.Y. Wang, and C. Wang: Corros. Eng. Sci. Techn., 2019, vol. 54, pp. 241–48.

J.T. Keiser, C.W. Brown, and R.H. Heidersbach: J. Electrochem. Soc., 1982, vol. 129, pp. 2686–89.

K. Asami and M. Kikuchi: Corros. Sci., 2003, vol. 45, pp. 2671–88.

L. Hao, S.X. Zhang, J.H. Dong, and W. Ke: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1724–30.

Acknowledgments

This work was financially supported by the Independent Project of State Key Laboratory of Rolling and Automation, Northeastern University (Grant No. ZZ202001), National Natural Science Foundation of China (Grant No. 51904071), the Key Research and Development Program of Hebei Province of China (Grant No. 18211019D), and Technical Development Program between HBIS Company Limited and NEU (Contract No. 2019040200044).

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, W., Zhao, Y., Feng, Y. et al. Structure and Electrochemical Behavior of the Rust on 690 MPa Grade Construction Steel in a Simulated Industrial Atmosphere. Metall Mater Trans A 53, 3044–3056 (2022). https://doi.org/10.1007/s11661-022-06725-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06725-y