Abstract

The effect of Pb on the creep properties of Ni-base single crystal superalloy was evaluated and compared with the reference data of polycrystalline superalloys. Alloy variants containing 0.04 (no Pb added), 0.9, and 31 ppm of Pb were prepared, and creep tests under different temperatures and stresses (i.e., 800/735, 900/392, 1000/245, 1100/137, and 1150 °C/137 MPa) as well as microstructural observations were conducted. The initial microstructure, such as the γ′ size and volume fraction of γ′, and the γ/γ′ microstructure after the creep test, such as the extent of raft structure formation, were almost identical in all the alloy variants. Moreover, the extent of topologically close-packed or precipitate phase formation could not be correlated with the Pb content. Based on these results and those of the creep tests, it was concluded that Pb did not affect the creep rupture life. In single crystal superalloy, no grain boundary exists, and the results of the field-emission electron-probe microanalysis indicated that Pb was dispersed in the substrate and its segregation did not occur during the creep test. Thus, in contrast to the Ni-base polycrystalline superalloy, no negative effect of Pb on the creep properties of the Ni-base single crystal superalloy was detected.

Similar content being viewed by others

References

K. Kawagishi, A. Yeh, T. Yokokawa, T. Kobayashi, Y. Koizumi, and H. Harada: Superalloys 2012, 2012, pp. 189–95.

T. Kobayashi, Y. Koizumi, H. Harada, T. Yokokawa, J.X. Zhang, A. Sato, and A. Sato: J. Jpn. Inst. Met., 2005, vol. 69, pp. 241–44.

W. Song, X.G. Wang, J.G. Li, L.H. Ye, G.C. Hou, Y.H. Yang, J.L. Liu, J.D. Liu, W.L. Pei, Y.Z. Zhou, and X.F. Sun: J. Mater. Sci. Eng. A., 2020, vol. A772, pp. 1–10.

L. Liu, J. Meng, J. Liu, M. Zou, H. Zhang, X. Sun, and Y. Zhou: J. Mater. Sci. Technol. (Shenyang, China), 2019, vol. 35, pp. 1917–24.

A. Heckl, S. Neumeier, M. Göken, and R.F. Singer: J. Mater. Sci. Eng. A., 2011, vol. A528, pp. 3435–44.

A.C. Yeh and S. Tin: Scr. Mater., 2004, vol. 52, pp. 519–24.

R.T. Holt and W. Wallace: Int. Met. Rev., 1976, vol. 21, pp. 1–24.

T.G. Gibbons: Mater. Sci. Technol., 1985, vol. 1, pp. 1033–39.

G.B. Thomas and T.B. Gibbons: Met. Technol. (London), 1979, vol. 6, pp. 95–101.

S. Utada, Y. Joh, M. Osawa, T. Yokokawa, T. Kobayashi, K. Kawagishi, S. Suzuki, and H. Harada: Superalloys 2016, 2016, pp. 591–99.

H. Harada, K. Kawagishi, T. Kobayashi, T. Yokokawa, M. Osawa, M. Yuyama, S. Suzuki, Y. Joh, and S. Utada: US Patent, patent number 10689741 (2020.06.23).

G.L.R. Durber and M. Boneham: Met. Technol. (London), 1984, vol. 11, pp. 428–37.

O.P. Sinha, M. Chatterjee, V.V.R.S. Sarma, and S.N. Jha: Bull. Mater. Sci., 2005, vol. 28, pp. 379–82.

D.A. Ford: Met. Technol. (London), 1984, vol. 11, pp. 438–45.

Y. Iijima and K. Kakehi: J. Jpn. Inst. Met., 2014, vol. 78, pp. 201–04.

S. Osgerby and T.G. Gibbons: Mater. Sci. Eng. A., 1992, vol. 157, pp. 63–71.

G.B. Thomas and T.B. Gibbons: Mater. Sci. Eng., 1984, vol. 67, pp. 13–23.

Y. Takata, T. Sugiyama, T. Yokokawa, M. Osawa, M. Yuyama, K. Kawagishi, J. Uzuhashi, T. Ohkubo, H. Harada, and S. Suzuki: National Institute for Materials Science and Waseda University, Japan, unpublished research, 2021.

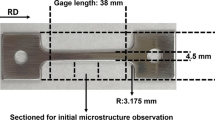

JIS Z2271, 2010, “Metallic materials-Uniaxial creep testing in tension-Method of test”.

S. Utada, Y. Joh, M. Osawa, T. Yokokawa, T. Sugiyama, T. Kobayashi, K. Kawagishi, S. Suzuki, and H. Harada: Metall. Mater. Trans. A., 2018, vol. 49A, pp. 4029–41.

N. Matan, D.C. Cox, P. Carter, M.A. Rist, C.M.F. Rae, and R.C. Reed: Acta Mater., 1999, vol. 47, pp. 1549–63.

C.M.F. Rae and R.C. Reed: Acta Mater., 2007, vol. 55, pp. 1067–81.

R.C. Reed, N. Matan, D.C. Cox, M.A. Rist, and C.M.F. Rae: Acta Mater., 1999, vol. 47, pp. 3367–81.

J. Coakley, R.C. Reed, J.L.W. Warwick, K.M. Rahman, and D. Dye: Acta Mater., 2012, vol. 60, pp. 2729–38.

C.M.F. Rae and L. Zhang: Mater. Sci. Technol., 2009, vol. 25, pp. 228–35.

T. Murakumo, Y. Koizumi, K. Kobayashi, and H. Harada: Superalloys 2004, 2004, pp. 155–62.

J.X. Zhang, T. Murakumo, Y. Koizumi, T. Kobayashi, H. Harada, and S. Masaki, JR: Metall. Mater. Trans. A., 2002, vol. 33A, pp. 3741–46.

A. Sato, T. Yokokawa, Y. Koizumi, T. Kobayashi, and H. Harada: J. Jpn. Inst. Met., 2005, vol. 69, pp. 691–94.

T. Yokokawa, M. Osawa, K. Nishida, Y. Koizumi, T. Kobayashi, and H. Harada: J. Jpn. Inst. Met., 2004, vol. 68, pp. 138–41.

Q. Feng, T.K. Nandy, and T.M. Pollock: Mater. Sci. Eng. A., 2004, vol. 373A, pp. 239–49.

Acknowledgments

The authors are grateful to Dr. Michinari Yuyama of Superalloys and High Temperature Materials Group at NIMS for conducting the creep tests. This work was supported by Council for Science, Technology and Innovation (CSTI), Cross-ministerial Strategic Innovation Promotion Program (SIP), “Materials Integration for revolutionary design system of structural materials” (Funding agency: JST).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Horie, T., Kawagishi, K., Takata, Y. et al. Creep Durability of Ni-Base Single Crystal Superalloy Containing Pb Impurity. Metall Mater Trans A 53, 2627–2641 (2022). https://doi.org/10.1007/s11661-022-06692-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06692-4