Abstract

The effect of ultrasonic vibration on the deformation mechanism of a TRIP-assisted steel is comprehensively studied based on micro-tensile tests. Lower flow stress and work hardening rate are observed in ultrasonically assisted (UA) conditions. Digital image correlation (DIC) analysis reveals the change in strain distribution and formation of Lüders-like deformation bands under superimposed UA. Electron backscatter diffraction (EBSD) characterization shows that at the same strain, UA reduces the fraction of retained austenite that is transformed to martensite, indicating a delayed martensitic transformation process. Additionally, EBSD reveals less low-angle grain boundaries and geometrically necessary dislocations with UA. All these microstructure modifications contribute to reduced flow stress and the change of strain distribution during deformation.

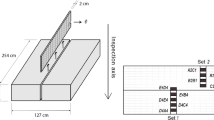

(Figure adapted with permission from Ref. [54])

Similar content being viewed by others

References

O. Bouaziz, H. Zurob, and M. Huang: Steel Res. Int., 2013, vol. 84, pp. 937–47. .

M.J. Sohrabi, M. Naghizadeh, and H. Mirzadeh: Arch. Civ. Mech. Eng., 2020, vol. 20, p. 124. .

P.J. Jacques, Q. Furnémont, F. Lani, T. Pardoen, and F. Delannay: Acta Mater., 2007, vol. 55, pp. 3681–93. .

S. Kumar, C.S. Wu, G.K. Padhy, and W. Ding: J. Manuf. Process., 2017, vol. 26, pp. 295–322. .

F. Blaha and B. Langenecker: Naturwissenschaften., 1955, vol. 42, pp. 1–10. .

K.F. Graff: Ultrasonic Metal Forming: Materials, in Power Ultrasonics. J.A. Gallego-Juárez and K.F. Graff, eds., Woodhead Publishing, Oxford, 2015, pp. 337–76.

B. Langenecker: IEEE Trans. Sonics Ultrason., 1966, vol. 13, pp. 1–8. .

N.A. Tyapunina, V.V. Blagoveshchenskii, G.M. Zinenkova, and Y.A. Ivashkin: Sov. Phys. J., 1982, vol. 25, pp. 569–78. .

H. Huang, A. Pequegnat, B.H. Chang, M. Mayer, D. Du, and Y. Zhou: J. Appl. Phys., 2009, vol. 106, p. 113514. .

I. Lum, H. Huang, B.H. Chang, M. Mayer, D. Du, and Y. Zhou: J. Appl. Phys., 2009, vol. 105, p. 024905. .

T. Jimma, Y. Kasuga, N. Iwaki, O. Miyazawa, E. Mori, K. Ito, and H. Hatano: J. Mater. Process. Technol., 1998, vol. 80–81, pp. 406–12. .

C. Bunget and G. Ngaile: Ultrasonics., 2011, vol. 51, pp. 606–16. .

J.-C. Hung and C. Hung: Ultrasonics., 2005, vol. 43, pp. 692–8. .

R. Cheng, N. Wiley, M. Short, X. Liu, and A. Taub: Procedia Manuf., 2019, vol. 34, pp. 186–92. .

G.A. Malygin: Phys. Solid State., 2000, vol. 42, pp. 72–8. .

G.E. Nevill: Effect of vibrations on the yield strength of a low carbon steel, Rice University, 1957.

H.O.K. Kirchner, W.K. Kromp, F.B. Prinz, and P. Trimmel: Mater. Sci. Eng., 1985, vol. 68, pp. 197–206. .

Y. Daud, M. Lucas, and Z. Huang: J. Mater. Process. Technol., 2007, vol. 186, pp. 179–90. .

M. Hoseini, M. Shalvandi, and A. Salimiasl: Modares Mech. Eng., 2018, vol. 18, pp. 40–5. .

R.K. Dutta, R.H. Petrov, R. Delhez, M.J.M. Hermans, I.M. Richardson, and A.J. Böttger: Acta Mater., 2013, vol. 61, pp. 1592–602. .

K.W. Siu and A.H.W. Ngan: Mater. Sci. Eng. A., 2013, vol. 572, pp. 56–64. .

K.W. Siu, A.H.W. Ngan, and I.P. Jones: Int. J. Plast., 2011, vol. 27, pp. 788–800. .

F. Ahmadi, M. Farzin, and M. Mandegari: Ultrasonics., 2015, vol. 63, pp. 111–7. .

C.J. Wang, Y. Liu, B. Guo, D.B. Shan, and B. Zhang: Mater. Des., 2016, vol. 112, pp. 246–53. .

H. Zhou, H. Cui, and Q.H. Qin: J. Mater. Process. Technol., 2018, vol. 251, pp. 146–59. .

T. Liu, J. Lin, Y. Guan, Z. Xie, L. Zhu, and J. Zhai: Ultrasonics., 2018, vol. 89, pp. 26–33. .

T. Wen, L. Wei, X. Chen, and C. Pei: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 70–6. .

J. Kang, X. Liu, and M. Xu: Mater. Sci. Eng. A, 2020, vol. 785, p. 139364.

ArcelorMittal: TRIP (TRansformation Induced Plasticity) steels, https://automotive.arcelormittal.com/products/flat/first_gen_AHSS/TRIP. Accessed 23 June 2021.

H. Li, G. Sun, G. Li, Z. Gong, D. Liu, and Q. Li: Mater. Des., 2011, vol. 32, pp. 3272–9. .

A.W. Wilson, J.D. Madison, and G. Spanos: Scr. Mater., 2001, vol. 45, pp. 1335–40. .

M.M. Nowell, S.I. Wright, and J.O. Carpenter: in Materials Processing and Texture. John Wiley & Sons, Inc., Hoboken, NJ, 2008, pp. 285–92.

J. Shi, X. Sun, M. Wang, W. Hui, H. Dong, and W. Cao: Scr. Mater., 2010, vol. 63, pp. 815–8. .

L. Luo, W. Li, L. Wang, S. Zhou, and X. Jin: Mater. Sci. Eng. A., 2017, vol. 682, pp. 698–703. .

Z.H. Cai, H. Ding, R.D.K. Misra, and Z.Y. Ying: Acta Mater., 2015, vol. 84, pp. 229–36. .

X.G. Wang, L. Wang, and M.X. Huang: Mater. Sci. Eng. A., 2016, vol. 674, pp. 59–63. .

M. Zhang, R. Li, J. Ding, H. Chen, J.-S. Park, J. Almer, and Y.-D. Wang: Mater. Res. Lett., 2018, vol. 6, pp. 662–7. .

Y. Zhang and H. Ding: Mater. Sci. Eng. A., 2018, vol. 733, pp. 220–3. .

H. Wang, Y. Zhang, G. Yuan, J. Kang, Y. Wang, R.D.K. Misra, and G. Wang: Mater. Sci. Eng. A., 2018, vol. 737, pp. 176–81. .

T. Brlić, S. Rešković, F. Vodopivec, and I. Jandrlić: Metalurgija., 2018, vol. 57, pp. 357–9. .

S.J. Kim, C.G. Lee, I. Choi, and S. Lee: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2001, vol. 32, pp. 505–14.

K. Lee, J.H. Ryu, S.W. Lee, W.H. Lee, J.I. Kim, and D.W. Suh: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2016, vol. 47, pp. 5259–65.

C.H. Seo, K.H. Kwon, K. Choi, K.H. Kim, J.H. Kwak, S. Lee, and N.J. Kim: Scr. Mater., 2012, vol. 66, pp. 519–22. .

R. Blondé, E. Jimenez-Melero, L. Zhao, J.P. Wright, E. Brück, S. Van Der Zwaag, and N.H. Van Dijk: Acta Mater., 2012, vol. 60, pp. 565–77. .

Y.B. Xu, Y. Zou, Z.P. Hu, D.T. Han, S.Q. Chen, and R.D.K. Misra: Mater. Sci. Eng. A., 2017, vol. 698, pp. 126–35. .

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A., 2010, vol. 527, pp. 2738–46. .

Y. Sakuma, D.K. Matlock, and G. Krauss: Metall. Trans. A., 1992, vol. 23, pp. 1221–32. .

J.H. Ryu, J.I. Kim, H.S. Kim, C.-S. Oh, H.K.D.H. Bhadeshia, and D.-W. Suh: Scr. Mater., 2013, vol. 68, pp. 933–6. .

M. Naghizadeh and H. Mirzadeh: Steel Res. Int., 2019, vol. 90, p. 1900153. .

Z.C. Li, H. Ding, R.D.K. Misra, and Z.H. Cai: Mater. Sci. Eng. A., 2017, vol. 679, pp. 230–9. .

E. Emadoddin, A. Akbarzadeh, and G.H. Daneshi: Mater. Sci. Eng. A., 2007, vol. 447, pp. 174–9. .

C. Chisholm, H. Bei, M.B. Lowry, J. Oh, S.A. Syed Asif, O.L. Warren, Z.W. Shan, E.P. George, and A.M. Minor: Acta Mater., 2012, vol. 60, pp. 2258–64.

Y. Tomita and T. Iwamoto: Int. J. Mech. Sci., 1995, vol. 37, pp. 1295–305. .

S. Curtze, V.T. Kuokkala, M. Hokka, and P. Peura: Mater. Sci. Eng. A., 2009, vol. 507, pp. 124–31. .

X. Liu, S. Lan, and J. Ni: Mater. Sci. Eng. A., 2013, vol. 582, pp. 211–8. .

J.R. Patel and M. Cohen: Acta Metall., 1953, vol. 1, pp. 531–8. .

T. Suzuki, H. Kojima, K. Suzuki, T. Hashimoto, S. Koike, and M. Ichihara: Scr. Metall., 1976, vol. 10, pp. 353–8. .

E. Cakmak, H. Choo, K. An, and Y. Ren: Acta Mater., 2012, vol. 60, pp. 6703–13. .

Acknowledgments

This work was supported by National Science Foundation CMMI AM program [Grant Number: 2019238]. Electron microscopy was performed at the Center for Electron Microscopy and Analysis (CEMAS) at The Ohio State University.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 17, 2021; accepted July 12, 2021.

Rights and permissions

About this article

Cite this article

Kang, J., Liu, X. Ultrasonic Effect on the Deformation Behavior and Microstructure Evolution of a TRIP-Assisted Steel. Metall Mater Trans A 52, 4468–4478 (2021). https://doi.org/10.1007/s11661-021-06398-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06398-z