Abstract

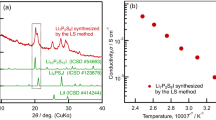

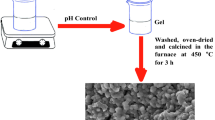

Aluminum-matrix nanocomposites offer advantageous properties over conventional aluminum alloys. However, controlling the size and size distribution of ceramic nanoparticles during in situ synthesis at high temperatures has been a long-term challenge due to a lack of effective size-control mechanisms. Here, we successfully synthesized titanium diboride (TiB2) nanoparticles with an unprecedented narrow size distribution in molten aluminum. The average size of TiB2 nanoparticles was tunable from 22.1 to 171.4 nm by solely controlling the reaction temperature under a diluted reactant salt solution. To uncover the mechanism of particle size control, an interface diffusion-controlled model was developed. The dilution of reactant salt was crucial to achieve a steady reaction environment while confining the growth of the particles in a shallow region. The model suggests that the average size of as-synthesized nanoparticles is mostly controlled by reaction temperature and unaffected by the titanium salt concentration in a diluted solution due to a steady diffusion of titanium and boron. Temperature controls the diffusion of reactants and nucleation rate to dictate the average size of the as-synthesized nanoparticles.

Similar content being viewed by others

References

J. Geng, G. Liu, T. Hong, M. Wang, D. Chen, N. Ma, and H. Wang: J. Alloys Compd., 2019, vol. 775, pp. 193–201.

C. Mallikarjuna, S.M. Shashidhara, U.S. Mallik, and K.I. Parashivamurthy: Mater. Des., 2011, vol. 32, pp. 3554–9.

L.-Y. Chen, J.-Q. Xu, H. Choi, M. Pozuelo, X. Ma, S. Bhowmick, J.-M. Yang, S. Mathaudhu, and X.-C. Li: Nature, 2015, vol. 528, pp. 539–43.

Q. Zhang and D.L. Chen: Scr. Mater., 2004, vol. 51, pp. 863–7.

Z.Z. Chen and K. Tokaji: Mater. Lett., 2004, vol. 58, pp. 2314–21.

C. Cao, L. Chen, J. Xu, J. Zhao, M. Pozuelo, and X. Li: Mater. Lett., 2016, vol. 174, pp. 213–6.

C. Cao, W. Liu, Z. Liu, J. Xu, I. Hwang, I. De Rosa, and X. Li: Mater. Des., 2018, vol. 146, pp. 163–71.

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, and T.M. Pollock: Nature, 2017, vol. 549, pp. 365–9.

M. Sokoluk, C. Cao, S. Pan, and X. Li: Nat. Commun., 2019, vol. 10, p. 98.

A. Javadi, C. Cao, and X. Li: Procedia Manuf., 2017, vol. 10, pp. 531–5.

W. Liu, C. Cao, J. Xu, X. Wang, and X. Li: Mater. Lett., 2016, vol. 185, pp. 392–5.

Y. Yang, J. Lan, and X. Li: Mater. Sci. Eng. A, 2004, vol. 380, pp. 378–83.

A.B. Pandey, R.S. Mishra, and Y.R. Mahajan: Mater. Sci. Eng. A, 1994, vol. 189, pp. 95–104.

J. Fjellstedt and A.E.W. Jarfors: Mater. Sci. Eng. A, 2005, vol. 413–414, pp. 527–32.

Y. Tang, Z. Chen, A. Borbély, G. Ji, S.Y. Zhong, D. Schryvers, V. Ji, and H.W. Wang: Mater. Charact., 2015, vol. 102, pp. 131–36.

N. El-Mahallawy, M.A. Taha, A.E.W. Jarfors, and H. Fredriksson: J. Alloys Compd., 1999, vol. 292, pp. 221–9.

P. Moldovan and M. Butu: J. Eng. Sci. Innov., 2019, vol. 4, pp. 285–300.

A.E. Karantzalis, A. Lekatou, M. Georgatis, V. Poulas, and H. Mavros: J. Mater. Eng. Perform., 2011, vol. 20, pp. 198–202.

Y. Liang, J. Zhou, S. Dong, and T. Yang: J. Wuhan Univ. Technol. Mater Sci Ed, 2008, vol. 23, p. 342.

Z. Liu, Q. Han, Z. Huang, and J. Xing: Metall. Mater. Trans. A, 2016, vol. 47, pp. 916–26.

C. Cao, W. Liu, A. Javadi, H. Ling, and X. Li: Procedia Manuf., 2017, vol. 10, pp. 634–40.

A. Javadi, S. Pan, C. Cao, G. Yao, and X. Li: Mater. Lett., 2018, vol. 229, pp. 107–10.

N.T.K. Thanh, N. Maclean, and S. Mahiddine: Chem. Rev., 2014, vol. 114, pp. 7610–30.

M.X. Guo, M.P. Wang, K. Shen, L.F. Cao, Z. Li, and Z. Zhang: J. Alloys Compd., 2008, vol. 460, pp. 585–9.

M. Estruga, L. Chen, H. Choi, X. Li, and S. Jin: ACS Appl. Mater. Interfaces, 2013, vol. 5, pp. 8813–9.

L. Anestiev, L. Froyen, and L. van Vugt: J. Appl. Phys., 2000, vol. 88, pp. 2130–7.

L.-Y. Chen, J.-Q. Xu, H. Choi, H. Konishi, S. Jin, and X.-C. Li: Nat. Commun., 2014, vol. 5, p. 3879.

J. Xu: UCLA, 2015.

A.E. Nielsen: J. Phys. Chem., 1961, vol. 65, pp. 46–9.

L. Wang: EPJ Web Conf., 2017, vol. 151, p. 02004.

T. Wang, F. Zhang, L. Yang, X.W. Fang, S.H. Zhou, M.J. Kramer, C.Z. Wang, K.M. Ho, and R.E. Napolitano: Sci. Rep., 2015, vol. 5, pp. 1–9.

X. Wang, J. Song, W. Vian, H. Ma, and Q. Han: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3285–90.

M. Emamy, M. Mahta, and J. Rasizadeh: Compos. Sci. Technol., 2006, vol. 66, pp. 1063–6.

Q. Li and Y.-S. Jun: Commun. Chem., 2018, vol. 1, pp. 1–9.

K.L. Tee, L. Lu, and M.O. Lai: Compos. Struct., 1999, vol. 47, pp. 589–93.

A. Chrysanthou and G. Erbaccio: J. Mater. Sci., 1995, vol. 30, pp. 6339–44.

E. Taheri-Nassaj, M. Kobashi, and T. Choh: Scr. Mater., 1997, vol. 37, pp. 605–14.

I. Gotman, M.J. Koczak, and E. Shtessel: Mater. Sci. Eng. A, 1994, vol. 187, pp. 189–99.

C. Biselli, D.G. Morris, and N. Randall: Scr. Metall. Mater., 1994, vol. 30, pp. 1327–32.

L. Lu, M.O. Lai, X.P. Niu, and H.N. Ho: Z. Fuer Met. Res. Adv. Tech., 1998, vol. 89, pp. 567–72.

X. Liu, Y. Liu, D. Huang, Q. Han, and X. Wang: Mater. Sci. Eng. A, 2017, vol. 705, pp. 55–61.

C.F. Feng and L. Froyen: J. Mater. Sci., 2000, vol. 35, pp. 837–50.

G. Han, W. Zhang, G. Zhang, Z. Feng, and Y. Wang: Mater. Sci. Eng. A, 2015, vol. 633, pp. 161–8.

D. Chen, Z. Chen, P. Zhang, Y.J. Zhang, H. Ma, and H.W. Wang: Adv. Mater. Res., 2012, vol. 535–537, pp. 1005–10.

L. Lu, M.O. Lai, and F.L. Chen: Acta Mater., 1997, vol. 45, pp. 4297–309.

M. Wang, D. Chen, Z. Chen, Y. Wu, F. Wang, N. Ma, and H. Wang: Mater. Sci. Eng. A, 2014, vol. 590, pp. 246–54.

J.V. Wood, P. Davies, and J.L.F. Kellie: Mater. Sci. Technol., 1993, vol. 9, pp. 833–40.

S. Lakshmi, L. Lu, and M. Gupta: J. Mater. Process. Technol., 1998, vol. 73, pp. 160–6.

J. Xue, J. Wang, Y. Han, C. Chen, and B. Sun: Trans. Nonferrous Met. Soc. China, 2012, vol. 22, pp. 1012–7.

Y. Chen and D.D.L. Chung: J. Mater. Sci., 1996, vol. 31, pp. 311–5.

K. Sivaprasad, S.P.K. Babu, S. Natarajan, R. Narayanasamy, B.A. Kumar, and G. Dinesh: Mater. Sci. Eng. A, 2008, vol. 498, pp. 495–500.

Y. Han, X. Liu, and X. Bian: Compos. Part Appl. Sci. Manuf., 2002, vol. 33, pp. 439–44.

M.A. Herbert, C. Sarkar, R. Mitra, and M. Chakraborty: Metall. Mater. Trans. A, 2007, vol. 38, pp. 2110–26.

A. Mandal, R. Maiti, M. Chakraborty, and B. Murty: Mater. Sci. Eng. A, 2004, vol. 386, pp. 296–300.

M. Mandal and R. Mitra: Mater. Charact., 2018, vol. 146, pp. 267–78.

Z.Y. Ma, J. Bi, Y.X. Lu, H.W. Shen, and Y.X. Gao: Compos. Interfaces, 1993, vol. 1, pp. 287–91.

Z.Y. Ma, J.H. Li, S.X. Li, X.G. Ning, Y.X. Lu, and J. Bi: J. Mater. Sci., 1996, vol. 31, pp. 741–7.

A.K. Kuruvilla, K.S. Prasad, V.V. Bhanuprasad, and Y.R. Mahajan: Scr. Metall. Mater., 1990, vol. 24, pp. 873–8.

Z. Li, D. Chen, H. Wang, E.J. Lavernia, and A. Shan: J. Mater. Res. Warrendale, 2014, vol. 29, pp. 2514–24.

J.P. Tu, N.Y. Wang, Y.Z. Yang, W.X. Qi, F. Liu, X.B. Zhang, H.M. Lu, and M.S. Liu: Mater. Lett., 2002, vol. 52, pp. 448–52.

Acknowledgement

This work was supported by MetaLi, LLC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 11, 2020; accepted March 19, 2021.

Rights and permissions

About this article

Cite this article

Yuan, J., Yao, G., Pan, S. et al. Size Control of In Situ Synthesized TiB2 Particles in Molten Aluminum. Metall Mater Trans A 52, 2657–2666 (2021). https://doi.org/10.1007/s11661-021-06260-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06260-2