Abstract

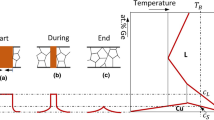

A new numerical model is developed for transient liquid phase (TLP) bonding involving two solid–liquid interfaces that concurrently undergo two-dimensional (2D) or three-dimensional (3D) migration in contrast to previous models in the literature where two solid–liquid interfaces are assumed to undergo one-dimensional (1D) migration. The developed model which incorporates variable diffusivity and conserves solute by using a unique hybrid explicit–fully implicit approach and an adaptable space discretization based on Murray–Landis transformation, respectively, is used to investigate the kinetics of the process and major predictions of the model are experimentally validated. It is found that in contrast to the case of 1D migration, despite matching material and bonding conditions, there is a transition from conventional symmetric solidification behavior to asymmetric solidification behavior such that the extent of isothermal solidification is consistently larger on the substrate in which curvature reduces along the direction of solute diffusion. Moreover, aside from what is generally known that the kinetics of isothermal solidification is controlled by diffusivity, equilibrium concentrations at the interface and initial substrate composition, this work shows that when the solid–liquid interface migrates in 2D or 3D, the kinetics is also significantly controlled by the type and degree of curvature at the migrating interface.

Similar content being viewed by others

References

P. Davies, A. Johal, H. Davies, S. Marchisio, Int. J. Adv. Manuf. Technol. 103, 441–452 (2019)

Y. Fang, X. Jiang, D. Mo, D. Zhu, Z. Luo, Int. J. Adv. Manuf. Technol. 102, 2845–2863 (2019)

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, K. Nakashima, Mater. Sci. Eng. 755A, 37–49 (2019)

T. Lin, H. Li, P. He, H. Wei, L. Li, J. Feng, Intermetallics 37, 59–64 (2013)

S.S.S. Afghahi, A. Ekrami, S. Farahany, A. Jahangiri, Philos. Mag. 94(11), 1166–1176 (2014)

N. Sheng, J. Liu, T. Jin, X. Sun and Z. Hu: Philos. Mag., 2014, vol. 94(11), pp. 12, 19–34.

J.E. Ramirez, S. Liu, Weld. J. 71(10), 365–376 (1992)

R. Asthana, J. Colloid Interface Sci. 158, 146–151 (1993)

Y. Zhou, J. Mater. Sci. Lett. 20, 841–844 (2001)

T.C. Illingworth, I.O. Golosnoy, V. Gergely, T.W. Clyne, Proc. IV Int. Conf. Temp. Capillarity 40, 2505–2511 (2005)

T.C. Illingworth, I.O. Golosnoy, J. Comput. Phys. 209(1), 207–225 (2005)

B. Binesh, A.J. Gharehbagh, J. Mater. Sci. Technol. 32(11), 1137–1151 (2016)

K. Bai, F.L. Ng, T.L. Tan, T. Li, D. Pan, J. Alloys Compd. 699, 1084–1094 (2017)

M.I. Saleh, H.J. Roven, T.I. Khan, T. Iveland, J. Manuf. Mater. Process (2018). https://doi.org/10.3390/jmmp2030058

A. Ghanbar, D.E. Michael, O.A. Ojo, Philos. Mag. 99(17), 2169–2184 (2019)

J. Crank, The Mathematics of Diffusion (Oxford University Press, Oxford, 1975), pp. 112–118

W. Kass, M. O’Keeffe, J. Appl. Phys. 37(6), 2377–2379 (1966)

M. Ghezzo, J. Electrochem. Soc. 120(8), 1123–1127 (1973)

W.D. Murray, F. Landis, J. Heat Transf. 81(2), 106–112 (1959)

O.C. Afolabi, O.A. Ojo, Int. J. Adv. Manuf. Technol. 110, 2295–2304 (2020)

G.S.C.R. Houska, F. Dietrich, G. Subbaraman, Thin Solid Films 44, 217–231 (1977)

K.A. Ellis, R.A. Buhrman, Appl. Phys. Lett. 74(7), 967–969 (1999)

L. Cheng-Wu, X. Hong-Lai, G. Cheng, L. Wen-biao, J. Geophys. Eng. 15, 315–329 (2018)

Acknowledgments

The authors gratefully acknowledge the financial support from NSERC of Canada.

Funding

This work was supported by the Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 12, 2020; accepted February 22, 2021.

Rights and permissions

About this article

Cite this article

Afolabi, O.C., Ojo, O.A. Development of a Numerical Model for Simulating Transient Liquid Phase (TLP) Bonding Involving Two Solid–Liquid Interfaces that Concurrently Undergo 2D or 3D Migration. Metall Mater Trans A 52, 2287–2297 (2021). https://doi.org/10.1007/s11661-021-06221-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06221-9