Abstract

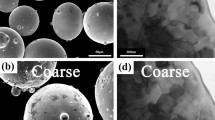

Short-circuit diffusion in fine-grained Ni samples processed by Spark Plasma sintering has been investigated by the radiotracer technique. Ni grain boundary self-diffusion is measured in samples sintered from commercial as-received powder and from a powder processed by mechanical milling (MM). Both samples displayed high penetration of the radiotracer and ultrafast diffusion rates, which exceed the diffusivity along general high-angle grain boundaries as they are present in pure polycrystalline Ni. A distinct profile was observed for each sample, dependent on the precursor powder. A stable penetration profile after pre-annealing at 773 K was observed when using commercial powder whereas a decrease in the grain boundary diffusion coefficient was depicted for the sample prepared from MM powders. The latter observation was interpreted in terms of partial relaxation of non-equilibrium grain boundaries generated by MM. Sample preparation by focused ion beam enabled the observation of interconnected porous paths in the sample prepared from commercial powders, which represent the main ultrafast diffusion path. A measurement of the surface diffusion coefficient through the pores was attempted considering a B–C-type kinetic regime. The isolated pores observed in the sample prepared from MM powder suggest a complex hierarchy of diffusion paths.

Similar content being viewed by others

References

J.M. Torralba, Improvement of Mechanical and Physical Properties in Powder Metallurgy. in: S. Hashmi (Ed.) Advanced forming technologies. Elsevier, Amsterdam, 2014, pp. 281-93.

W.B. James (2015) Powder Metallurgy Methods and Applications. In: W. Newkirk (Ed.) Powder Metal. ASM International, Cleveland

M. Suarez, A. Fernandez, J.L. Menendez, R. Torrecillas, H.U.J. Hennicke, R. Kirchner, and T. Kessel, Challenges and Opportunities for Spark Plasma Sintering: A Key Technology for a New Generation of Materials, in: B. Ertug (Ed.) Sintering Applications. IntechOpen, Dundas, 2013.

P. Ramakrishnan: Indian J. Hist. Sci., 1983, vol. 18, pp. 109-14.

D.A. Levina, L.I. Chernyshev, and N.V. Mikhailovskaya: Powder Metall. Met. Ceram., 2007, vol. 46, pp. 202-05.

L.A. Dobrzanski, Goals and Contemporary Position of Powder Metallurgy, in: L.A. Dobrzanski (Ed.) Powder Metallurgy. Fundamentals and Case Studies, IntechOpen, 2017, pp. 1-17.

T. Sekiguchi, K. Ono, H. Fujiwara, and K. Ameyama: Mater. Trans., 2010, vol. 51, pp. 39-45.

J. Gubicza, H.-Q. Bui, F. Fellah, and G. Dirras: J. Mater. Research, 2009, vol. 24, pp. 217-26.

Z. Zhang, D. Orlov, S.K. Vajpai, B. Tong, and K. Ameyama: Advanced Engineering Materials, 2015, vol. 17, pp. 791-95.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1-184.

B. Flipon, C. Keller, L. Garcia de la Cruz, E. Hug, and F. Barbe: Mater. Sci. Eng. A, 2018, 729, 249-56.

G.D. Dutel, D. Tingaud, P. Langlois, and G. Dirras: J. Mater. Sci., 2012, vol. 47, pp. 7926-31.

C. Sawangrat, O. Yamaguchi, S.K. Vajpai, and K. Ameyama: Mater. Trans., 2014, vol. 55, pp. 99-105.

Y. Zhao, T. Topping, J.F. Bingert, J.J. Thornton, A.M. Dangelewicz, Y. Li, W. Liu, Y. Zhu, Y. Zhou, and E.J. Lavernia: Adv. Mater., 2008, vol. 20, pp. 3028-33.

P. Knorr, J.G. Nam, and J.S. Lee: Metall. Mater. Trans. A, 2000, vol. 31, pp. 503-10.

S.V. Divinski, J.S. Lee, and C. Herzig: J. Metast. Nano. Mater., 2004, vol. 19, pp. 55-68.

D.B. Bober, A. Khalajhedayati, M. Kumar, and T.J. Rupert: Metall. Mater. Trans. A, 2016, vol. 47, pp. 1389-403.

S.V. Divinski, G. Reglitz, H. Rösner, Y. Estrin, and G. Wilde: Acta Mater., 2011, vol. 59, pp. 1974-85.

S.V. Divinski: Diffus. Found., 2015, vol. 5, pp. 57-73.

G. Wilde, and S.V. Divinski: Mater. Trans., 2019, vol. 60, pp. 1302-15.

H. Miyamoto: Mater. Trans., 2016, vol. 57, pp. 559-72.

A. Hasnaoui, H.V. Swygenhoven, and P.M. Derlet: Acta Mater., 2002, vol. 50, pp. 3927-39.

S.V. Divinski, G. Reglitz, I.S. Golovin, M. Peterlechner, R. Lapovok, Y. Estrin, and G. Wilde: Acta Mater., 2015, vol. 82, pp. 11-21.

D. Prokoshkina, L. Klinger, A. Moros, G. Wilde, E. Rabkin, and S.V. Divinski: Acta Mater., 2014, vol. 69, pp. 314-25.

A.A. Nazarov, A.E. Romanov, and R.Z. Valiev: Nanostruct. Mater., 1995, vol. 6, pp. 775-78.

G. Liang, J. Huot, S. Boily, A.V. Neste, and R. Schulz: J. Alloy Compd, 1999, vol. 292, pp. 247-52.

A. Zaluska, L. Zaluski, and J.O. Ström-Olsen: J. Alloy Compd, 1999, 288, 217-25.

V.M. Skripnyuk, E. Rabkin, Y. Estrin, and R. Lapovok: Acta Mater., 2004, vol. 52, pp. 405-14.

S. Poulat, B. Décamps, and L. Priester: Phil. Mag. A, 1999, vol. 79, pp. 2655-80.

A.A. Nazarov: Interface Sci., 2000, vol. 8, pp. 315-22.

S.V. Divinski, F. Hisker, Y.S. Kang, J.S. Lee, and C. Herzig: Interface Sci., 2003, vol. 11, pp. 67-80.

Y. Amouyal, S.V. Divinski, Y. Estrin, and E. Rabkin: Acta Mater., 2007, vol. 55, pp. 5968-79.

G. Cipolloni, M. Pellizzari, A. Molinari, M. Hebda, and M. Zadra: Powder Techn., 2015, vol. 275, pp. 51-59.

V. Randle: Mater. Charact., 2001, vol. 47, pp. 411-16.

A.H. King, and S. Shekhar: J. Mater. Sci., 2006, vol. 41, pp. 7675-82.

T. Borkar, and R. Banerjee: Mater. Sci. Eng. A, 2014, vol. 618, pp. 176-81.

L.G. Harrison: Trans. Faraday Soc., 1961, vol. 57, pp. 1191-99.

S.V. Divinski, G. Reglitz, and G. Wilde: Acta Mater., 2010, vol. 58, pp. 386-95.

A. Paul, T. Laurila, V. Vuorinen, and S.V. Divinski, Thermodynamics, Diffusion and Kirkendall Effect in Solids, Springer International Publishing Switzerland, 2014.

K. Maier, H. Mehrer, E. Lessmann, and W. Schüle: Phys. Stat. Sol. B, 1976, vol. 78, pp. 689-98.

D.L. Beke, I. Gödény, G. Erdélyi, and F.J. Kedves: Phil. Mag. A, 1987, vol. 56, pp. 659-71.

S.V. Divinski, F. Hisker, Y.S. Kang, J.S. Lee, and C. Herzig: Zeit. Metall., 2002, vol. 93, pp. 265-72.

S.V. Divinski, F. Hisker, Y.S. Kang, J.S. Lee, and C. Herzig: Acta Mater., 2004, vol. 52, pp. 631-45.

D. Prokoshkina, V.A. Esin, G. Wilde, and S.V. Divinski: Acta Mater., 2013, vol. 61, pp. 5188-97.

S.V. Divinski, M. Lohmann, C. Herzig, B. Straumal, B. Baretzky, and W. Gust: Phys. Rev. B, 2005, vol. 71, pp. 104104.

J. Ribbe, D. Baither, G. Schmitz, and S.V. Divinski: Scripta Mater., 2009, vol. 61, pp. 129-32.

R.T. Tung, and W.R. Graham: Surf. Sci., 1980, vol. 97, pp. 73-87.

L. García de la Cruz, B. Flipon, C. Keller, M. Martinez, and E. Hug: AIP Conf. Proc., 2017, vol. 1896, pp. 200002.

S.V. Divinski, J. Ribbe, D. Baither, G. Schmitz, G. Reglitz, H. Rösner, K. Sato, Y. Estrin, and G. Wilde: Acta Mater., 2009, vol. 57, pp. 5706-17.

R. Singh, J.H. Schneibel, S. Divinski, and G. Wilde: Acta Mater., 2011, vol. 59, pp. 1346-53.

S.V. Divinski, J. Ribbe, G. Reglitz, Y. Estrin, and G. Wilde: J. Appl. Phys., 2009, vol. 106, pp. 063502.

H. Gleiter: Prog. Mater. Sci., 1989, vol. 33, pp. 223-315.

Acknowledgments

This work was performed with the financial support of the program EQUIPEX GENESIS, Agence Nationale de la Recherche (Grant No. ANR-11-EQPX-0020) for dual-beam experiments. A partial financial support from the German Science Foundation (DFG) via research project is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 4, 2019.

Rights and permissions

About this article

Cite this article

García de la Cruz, L., Domenges, B., Divinski, S.V. et al. Ultrafast Atomic Diffusion Paths in Fine-Grained Nickel Obtained by Spark Plasma Sintering. Metall Mater Trans A 51, 3425–3434 (2020). https://doi.org/10.1007/s11661-020-05791-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05791-4