Abstract

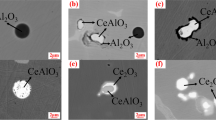

To investigate and clarify the roles and mechanism of Ce addition in grain refinement of primary δ-ferrite during solidification of steels, a Fe-4wt pct Si alloy, which can retain the primary δ-ferrite to room temperature after solidification, was used to evaluate the roles of Ce in refining the δ-ferrite. Experimental results showed that addition of small amount of Ce led to significant reduction in average grain size of the as-cast Fe-4wt pct Si alloy from 1906 ± 160 µm without Ce addition down to 998 ± 70 µm at 0.0260 wt pct Ce addition. For the purpose of investigating the grain refinement mechanism of Ce, the Equilib and Phase Diagram modules in the FactSage Software System were used to simulate the formation sequence and calculate fractions of the Ce-containing inclusions above the liquidus in various Fe-4wt pct Si alloys with different Ce, S and O contents. The predicted formation sequence was Ce2O3 > Ce2O2S > Ce2S3/Ce3S4. However, due to the low fraction of the oxide and sulfides formed, only the oxysulfide, Ce2O2S, was observed and verified in the experimental alloys at room temperature in a transmission electron microscopy and a scanning electron microscope that was equipped with the electron backscatter diffraction and energy-dispersive X-ray spectroscopy. Based on the crystallographic calculations using the edge-to-edge matching model together with previously determined orientation relationships between the δ-ferrite and Ce2O2S, it is considered that the heterogeneous nucleation of δ-ferrite on the in situ-formed Ce2O2S particles in the Fe-4wt pct Si alloy melt played a key role in grain refinement of the δ-ferrite. An inductively coupled plasma mass spectrometry was used to measure the amount of Ce solute in the ferrite after conducting low-temperature electrolysis to separate and filter out the Ce compounds. The calculation of the growth restriction parameter (β) using the Phase Diagram module in FactSage Software System indicated an almost negligible role of the Ce solute in the grain refinement of δ-ferrite. The present work clarifies previous uncleanness in understanding the grain refinement mechanism of δ-ferrite through Ce addition.

Similar content being viewed by others

References

P.S. Mohanty and J.E. Gruzleski: Acta Metall. Mater., 1995, vol. 43, pp. 2001-12.

F. Wang, D. Qiu, Z.L. Liu, J.A. Taylor, M.A. Easton and M.X. Zhang: Acta Mater., 2013, vol. 61, pp. 5636-45.

D.H. StJohn, M. Qian, M.A. Easton, P. Cao and Z. Hildebrand: Mater. Trans. A, 2005, vol. 36, pp. 1669-79.

Y. Ali, D. Qiu, B. Jiang, F.S. Pan and M.X. Zhang: J. Alloys Compd., 2015, vol. 619, pp. 639-51.

M.A. Easton, M. Qian, A. Prasad and D.H. StJohn: Curr. Opin. Solid State Mater. Sci., 2016, vol. 20, pp. 13-24.

M. Li, J.M. Li, Q. Zheng, D. Qiu, G. Wang and M.X. Zhang: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2902-12.

D.S. Sarma, A.V. Karasev and P.G. Jönsson: ISIJ Int., 2009. vol. 49, pp. 1063-74.

Y. Shan, X. Luo, X. Hu and S. Liu: J. Mater. Sci. Technol., 2011, vol. 27, pp. 352-8.

J. Fu, Q. Nie, W. Qiu, W. Qiu and J. Sun: J. Mater. Process. Technol., 2018, vol. 253, pp. 43-50.

Y. Nuri, T. Ohashi, T. Hiromoto and O. Kitamura: Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 399-407.

L.M. Wang, Q. Lin, L.J. Yue, L. Liu, F. Guo and F.M. Wang: J. Alloys Compd., 2008, vol. 451, pp. 534-7.

R.B. Tuttle: Int. J. Metalcast., 2016, vol. 10, pp. 1-11.

Y. Ji, M.X. Zhang and H. Ren: Metals, 2018, vol. 8, pp. 884.

J. Gao, P. Fu, H. Liu and D. Li: Metals, 2015, vol. 5, pp. 383-94.

L.N. Bartlett and B.R. Avila: Int. J. Metalcast, 2016, vol. 10, pp. 401-20.

H. Li, A. Mclean, J.W. Rutter and I.D. Sommerville: Metall. Mater. Trans. B, 1988, vol. 19, pp. 383-95.

A.Q. Wang, M. Li, D.Q. Ma, Q.J. Wu and J.P. Xie: Kem. Ind., 2016, vol. 65, pp. 11-6.

B.L. Bramfitt: Metall. Trans., 1970, vol. 1, pp. 1987-95.

F.F. Hao, B. Liao, D. Li, L.G. Liu, T. Dan, X.J. Ren and Q.X. Yang: J. Rare Earths, 2011, vol. 29, pp. 609-13.

P.M. Kelly and M.X. Zhang: Mater. Forum, 1999, vol. 23, pp. 41-62.

M.X. Zhang and P.M. Kelly: Acta Mater., 2005, vol. 53, pp. 1073-84.

M.X. Zhang and P.M. Kelly: Acta Mater., 2005, vol. 53, pp. 1085-96.

M.X. Zhang and P.M. Kelly: Prog. Mater. Sci., 2009, vol. 54, pp. 1101-70.

M.X. Zhang, P.M. Kelly, M.A. Easton and J.A. Taylor: Acta Mater., 2005, vol. 53, pp. 1427-38.

D. Qiu, M.X. Zhang and P.M. Kelly: Scripta Mater., 2009, vol. 61, pp. 312-5.

D. Qiu, M.A. Zhang, J.A. Taylor and P.M. Kelly: Acta Mater., 2009, vol. 57, pp. 3052-9.

M. Zhang, P.M. Kelly, M. Qian and J.A. Taylor: Acta Mater., 2005, vol. 53, pp. 3261-70.

Z. Liu, D. Qiu, F. Wang, J.A. Taylor and M. Zhang: Acta Mater., 2014, vol. 79, pp. 315-26.

Z. Liu, D. Qiu, F. Wang, J.A. Taylor and M. Zhang: J. Appl. Crystallogr., 2015, vol. 48, pp. 890-900.

A. Cibula: J. Inst. Met., 1949, vol. 76, pp. 321-60.

J.W. Rutter and B. Chalmers: Can. J. Phys., 1953, vol. 31, pp. 15-39.

W.A. Tiller, K.A. Jackson, J.W. Rutter and B. Chalmers: Acta Metall., 1953, vol. 1, pp. 428-37.

L.A. Tarshis, J.L. Walker and J.W. Rutter: Metall. Trans., 1971, vol. 2, pp. 2589-97.

I. Maxwell and A. Hellawell: Acta Metall., 1975, vol. 23, pp. 229-37.

M.A. Easton and D.H. StJohn: Acta Mater., 2001, vol. 49, pp.1867-78.

Z. Fan, F. Gao, L. Zhou and S.Z. Lu: Acta Mater., 2018, vol. 152, pp. 248-57.

D.H. Stjohn, M.A. Easton, M.Qian and J.A.Taylor: Metall. Mater. Trans. A, 2013, vol. 44, pp. 2935-49.

V.E. Bazhenov: Mater. Sci. Technol., 2015, vol. 31, pp. 1305-12.

H. Xu, L.D. Xu, S.J. Zhang and Q. Han: Scripta Mater., 2006, vol. 54, pp. 2191-6.

M. Easton and D. StJohn: Metall. Mater. Trans. A, 1999, vol. 30, pp. 1625-33.

F. Wang, Z. Liu, D. Qiu, J.A. Taylor, M.A. Easton and M.X. Zhang: Acta Mater., 2013, vol. 61, pp. 360-70.

Z.L. Liu, F. Wang, D. Qiu, J.A. Taylor and M.X. Zhang: Metall. Mater. Trans. A, 2013, vol. 44, pp. 4025-30.

M. Li, J.M. Li, Q. Zheng, D. Qiu, G. Wang and M.X. Zhang: Metall. Mater. Trans. A, 2018, vol. 49, pp. 2235-47.

Y.P. Ji, Y.M. Li, M.X. Zhang and H.P. Ren: Metall. Mater. Trans. A, 2019, vol. 50, pp. 1787-94.

R. Tuttle: Int. J. Metalcast., 2012, vol. 6, pp. 51-65.

T.B. Massalski, H. Okamoto, P.R. Subramanian and L. Kacprzak: Binary Alloy Phase Diagrams, 2nd ed., ASM International, Ohio, 1990.

Y. Ali, D. Qiu, B. Jiang, F.S. Pan and M.X. Zhang: Scripta Mater., 2016, vol. 114, pp. 103-7.

L.J. Yue, L.L. Wang and L.M. Wang: J. Rare Earths, 2014, vol. 35, pp. 20-6.

F. Pan, J. Zhang, H.L. Chen, Y.H. Su, C.L. Kuo, Y.H. Su, S.H. Chen, K.J. Lin, P.H. Hsieh and W.S. Hwang: Materials, 2017, vol. 9, pp. 1-19.

L.A. Smirnov, V.A. Rovnushkin, A.S. Oryshchenko, G.Y. Kalinin and V.G. Milyuts: Metallurgist, 2016, vol. 59, pp. 1053-61.

Y. Li, C. Liu, T. Zhang, M. Jiang and C. Peng: Metall. Mater. Trans. B, 2016, vol. 48, pp. 1-10.

C. Yang, Y. Luan, D. Li and Y. Li: J. Mater. Sci. Technol., 2019, vol. 35, pp. 1298-308.

M. Mikami and S. Nakamura: J. Alloys Compd., 2006, vol, 408, pp. 687-92.

S. Ohba, Y. Saito and Y. Noda: Acta Crystallogr. Sect. A, 1982, vol, 38, pp. 725-9.

B. Wu, M. Zinkevich, F. Aldinger, D.Z. Wen and L. Chen: J. Solid State Chem., 2007, vol. 180, pp. 3280-7.

W. H. Zachariasen: Acta Crystallogr., 1948, vol. 1, pp. 265-8.

A. Dönni, A. Furrer, P. Fischer and F. Hulliger: Phys. B, 1993, vol. 186-188, pp. 541-3.

T. Schleid and P. Lauxmann: ChemInform, 1999, vol. 30, pp. 1053-5.

Q. Ma: Acta Mater., 2007, vol. 55, pp. 943-53.

D. Qiu and M.X. Zhang: J. Alloys Compd., 2009, vol. 488, pp. 260-4.

H.T. Li, Y. Wang and Z. Fan: Acta Mater., 2012, vol. 60, pp. 1528-37.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans and D.J. Bristow: Acta Mater., 2000, vol. 48, pp. 2823-35.

Q. Ma, D.H. Stjohn and M.T. Frost: Scripta Mater., 2004, vol. 50, pp. 1115-9.

M. Easton and D. Stjohn: Metall. Mater. Trans. A, 2005, vol. 36, pp. 1911-20.

Acknowledgments

The authors are very grateful to the funding support from the National Natural Science Foundation of China (Grant Nos. 51761034 and 51261018) and the Natural Science Foundation of Inner Mongolia in China (Grant No. 2017MS0512). Additionally, the authors thank the financial support from the Inner Mongolia Science & Technology Plan.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 15, 2019.

Rights and permissions

About this article

Cite this article

Ji, Y.P., Li, Y.M., Zhang, M.X. et al. Grain Refinement Mechanism of the δ-Ferrite in Steels Through Cerium Addition. Metall Mater Trans A 51, 1707–1718 (2020). https://doi.org/10.1007/s11661-020-05645-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05645-z