Abstract

This study investigates the effect of grain/sub-grain size, boundary misorientation, and dislocation density on mechanical properties of nanostructured aluminum. A fully recrystallized high-purity aluminum was deformed to different strains from low to ultrahigh strains by a combination of conventional cold rolling and accumulative roll-bonding, followed by annealing for recovery and structural coarsening, to produce sub-grained samples dominated by low-angle boundaries and ultrafine-grained samples dominated by high-angle boundaries. The ultrafine-grained samples showed unusual discontinuous yielding and had a very high strength, which was positively deviated from the extrapolation of the Hall–Petch curve in coarse grains. On the other hand, sub-grained samples showed continuous yielding, and the strength was lower than that of ultrafine-grained samples at the same structural size. It is suggested that in the ultrafine-grained samples, due to lack of dislocation sources in the grains, extremely high stress is required for yielding, which is responsible for the unexpected discontinuous yielding and extra Hall–Petch strengthening. On the other hand, in the sub-grained samples, dislocations in the low-angle dislocation boundaries may act as active dislocation sources, leading to a lower yield stress.

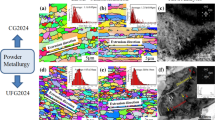

Adopted from Ref. [33]

Adopted from Ref. [33] (Color figure online)

Similar content being viewed by others

References

E.O. Hall: Proc. Phys. Soc., 1951, vol. B64, pp. 747-753.

N.J. Petch: J. Iron Steel Inst., 1953, vol. 174, pp. 25-28.

L.L. Shaw: J. Metals (JOM), 2000, vol. 52, pp. 41-45.

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zechetbauer, Y.T. Zhu: J. Metals (JOM), 2006, vol. 58, pp. 33-39.

A. Azushima, R. Kopp, A. Korhonen, D. Y. Yang, F. Micari, G. D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski and A. Yanagida: CIRP Annals – Manufacturing Tech., 2008, vol. 57, pp. 716-735.

M.A. Meyers, A. Mishra and D.J. Benson: Prog. Mater. Sci., 2006, vol. 51, pp. 427-556.

R.Z. Valiev, A.P. Zhilyaev and T.G. Langdon: Bulk Nanostructured Materials: Fundamentrals and Applications, Wiley, Hoboken, NJ, 2014.

R.Z. Valiev and Y. Zhu: Trans. Mater. Res. Soc. Japan, 2015, vol. 40, pp. 309-318.

C.Y. Yu, P.W. Kao and C.P. Cheng: Acta Mater., 2005, vol. 53, pp. 4019-4028.

N. Kamikawa, X. Huang, N. Tsuji and N. Hansen: Acta Mater., 2009, vol. 57, pp. 4198-4208.

G.M. Le, A. Godfrey and N. Hansen: Mater. Des., 2013, vol. 49, pp. 360-367.

K.N. Zhu, A. Godfrey, N. Hansen and X. D. Zhang: Mater. Des., 2017, vol. 117, pp. 95-103.

S. Gao, M. Chen, S. Chen, N. Kamikawa, A. Shibata and N. Tsuji: Mater. Trans., 2014, vol. 55, pp. 73-77.

S. Gao, M. Chen, M. Joshi, A. Shibata and N. Tsuji: J. Mater. Sci., 2014, vol. 49, pp. 6536-6542.

J.W. Wyrzykowski and M.W. Grabski: Mater. Sci. Eng., 1982, vol. 56, pp. 197-200.

Y.Z. Tian, S. Gao, L.J. Zhao, S. Lu, R. Pippan, Z.F. Zhang and N. Tsuji: Scripta Mater., 2018, vol. 142, pp. 88-91.

D. Terada, M. Inoue, H. Kitahara and N. Tsuji: Mater. Trans., 2008, vol. 49, pp. 41-46.

Z. Li, L. Fu and A. Shan: Mater. Letters, 2013, vol. 96, pp. 1-4.

N. Tsuji, Y. Ito, Y. Saito and Y. Minamino: Scripta Mater., 2002, vol. 47, pp. 893-899.

R. Saha, R. Ueji and N. Tsuji: Scripta Mater., 2013, vol. 68, pp. 813-816.

X. Huang, N. Tsuji and N. Hansen: Science, 2006, vol. 312, pp. 249-251.

T. Ohashi, M. Kawamukai and H.M. Zbib: Int. J. Plast., 2007, vol. 23, pp. 897-914.

Y. Aoyagi, T. Tsuru and T. Shimokawa: Int. J. Plast., 2014, vol. 55, pp. 43-57.

S. Cheng, J.A. Spencer and W.W. Milligan: Acta Mater., 2003, vol. 51, pp. 4505–4518.

M. Kato, T. Fujii and S. Onaka: Mater. Trans., 2008, vol. 49, pp. 1278-1283.

I.A. Ovid’ko and N.V. Skiba: Scripta Mater., 2012, vol. 67, pp. 13–16.

I.A. Ovid’ko, A.G. Sheinerman and R.Z. Valiev: Scripta Mater., 2014, vol. 76, pp. 45-48.

H. Van Swygenhoven, M. Spaczér and A. Caro: Nanostruct. Mater., 1998, vol. 10, pp. 819-828.

H. Van Swygenhoven, M. Spaczér, D. Farkas and A. Caro: Nanostruct. Mater., 1999, vol. 12, pp. 323-326.

K. Kinoshita, T. Shimokawa and T. Kinari: Mater. Trans., 2012, vol. 53, pp. 147-155.

J.W. Wyrzykowski and M.W. Grabski: Phil. Mag. A, 1986, vol. 53, pp. 505-520.

P.L. Sun, C.Y. Yu, P.W. Kao and C.P. Chang: Scripta Mater., 2005, vol. 52, pp. 265-269.

N. Kamikawa, T. Hirochi, and T. Furuhara: Proc. 33rd Risø Int. Symp. Mater. Sci. Nanomet. Status Perspect., Technical University of Denmark, 2012, pp. 257–64.

T. Hu, K. Ma, T.D. Topping, B. Saller, A. Yousefiani, J.M. Schoenung and E.J. Lavernia: Scripta Mater., 2014, vol. 78-79, pp. 25-28.

V.V. Polyakova, I.P. Semenova, A.V. Polyakov, D.K. Magomedova, Y. Huang and T.G. Langdon: Materials Letters, 2017, vol. 190, pp. 256-259.

J.R. Gatti and P.P. Bhattacharjee: J. Alloys Comp., 2014, vol. 615, pp. 950–961.

I. Zuiko and R. Kaibyshev: Mate. Sci. Eng. A, 2017, vol. 702, pp. 53-64.

T. Huang, L. Shuai, A. Wakeel, G. Wu, N. Hansen and X. Huang: Acta Mater., 2018, vol. 156, pp. 369-378.

Y. Saito, H. Utsunomiya, N. Tsuji and T. Sakai: Acta Mater., 1999, vol. 47, pp. 579-583.

L. Su, C. Lu, H. Li, G. Deng and K. Tieu: Mater. Sci. Eng. A, 2014, vol. 614, pp. 148–155.

Y.B. Zhang and O.V. Mishin: Mater. Charact., 2017, vol. 129, pp. 323–328.

N. Kamikawa, N. Tsuji, X. Huang and N. Hansen: Acta Mater., 2006, vol. 54, pp. 3055-3066.

R.K. Ham: Phil. Mag., 1961, vol. 6, pp. 1183-1184.

N. Kamikawa and N. Tsuji: Mater. Trans., 2016, vol. 57, pp. 1720-1728.

Y. Ito and Z. Horita: Mater. Sci. Eng. A, 2009, vol. 503, pp. 32–36.

N. Kamikawa and T. Furuhara: J. Mater. Process. Technol., 2013, vol. 213, pp. 1412-1418.

Y. Ito, K. Edalati and Z. Horita: Mater. Sci. Eng. A, 2017, vol. 679, pp. 428-434.

Z. Horita, K. Kishikawa, K. Kimura, K. Tatsumi and T.G. Langdon: Mater. Sci. Forum, 2007, vols. 558-559, pp. 1273-1278.

R.Z. Valiev, I.V. Alexandrov, Y.T. Zhu and T.C. Lowe: J. Mater. Res., 2002, vol. 17, pp. 5-8.

H.W. Höppel, J. May and M. Göken: Adv. Eng. Mater., 2004, vol. 6, pp. 781-784.

H.-W. Kim, S.-B. Kang, N. Tsuji and Y. Minamino: Acta Mater., 2005, vol. 53, pp. 1737-1749.

J.E. Bailey and P.B. Hirsch: Phil. Mag., 1960, vol. 5, pp. 485-497.

N. Hansen: Scripta Mater., 2004, vol. 51, pp. 801-806.

N. Hansen and X. Huang: Acta Mater., 1998, vol. 46, pp. 1827-1836.

G.W.C. Kaye and T.H. Laby: Tables of Physical and Chemical Constants, 14th ed., Longman, London, 1973, pp. 31.

G.I. Taylor: J. Inst. Metals, 1938, vol. 62, pp. 307-324.

W.G. Johnston: J. Appl. Phy., 1962, vol. 33, pp. 2716-2730.

E.O. Hall: Yield point phenomena in metals and alloys, Plenum Press, New York, 1970.

D.J. Lloyd: Metal Sci., 1980, vol. 14, pp. 193-198.

M.W. Grabski and R. Korski: Phil. Mag., 1970, vol. 22, pp. 707-715.

J.P. Hirth: Metall. Trans., 1972, vol. 3, pp. 3047-3067.

J. Kacher, B.P. Eftink, B. Cui and I.M. Robertson: Curr. Opin. Solid State Mater. Sci., 2014, vol. 18, pp. 227-243.

J.C.M. Li: Trans. Metall. Soc. AIME, 1963, vol. 227, pp. 239-247.

Acknowledgments

This research was financially supported partly by the Grant-in-Aid for Scientific Research on Innovative Area, “Bulk Nanostructured Metals” (Grant No. 22102006) and partly by the Grant-in-Aid for Research Activity Start-up (Grant No. 21860010), through the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan, which are gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 24, 2018.

Rights and permissions

About this article

Cite this article

Kamikawa, N., Hirochi, T. & Furuhara, T. Strengthening Mechanisms in Ultrafine-Grained and Sub-grained High-Purity Aluminum. Metall Mater Trans A 50, 234–248 (2019). https://doi.org/10.1007/s11661-018-5007-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5007-3