Abstract

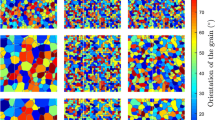

The effect of different initial structures on the simulation of microstructure evolution during normal grain growth was comparatively studied by using a two-dimensional phase-field model. Three methods, standard Voronoi construction, weighted Voronoi construction, and hand drawing, were used to generate the initial structures. For the hand-drawn initial structure, different boundary conditions, including periodic and gradient boundary conditions, were also applied. The phase-field simulation of normal grain growth in the succinonitrile–coumarin152 system was chosen as the benchmark, and compared with the experimental microstructure evolution. The phase-field simulated results generally conformed to Hillert’s theory, Von Neumann–Mullins law, and the experimental results. Different initial structures with similar initial grain size distribution showed similar grain size evolution. The simulation results for the “experimental” initial structure constructed by hand drawing showed best agreement with the experimental results during the early stage of grain growth process. With the increased time, the accuracy of simulation appeared strongly dependent on the grain numbers, and thus the gradient boundary condition is more suitable for long-time grain growth simulation than the periodic boundary condition. Overall, the combination of phase-field simulation and “experimental” initial microstructures allows the study of the grain growth in arbitrary polycrystalline materials, as demonstrated here for comprehensive study of austenite grain growth in two commercial high-strength steels.

Similar content being viewed by others

References

B. Zhu, R.J. Asaro, P. Krysl, K. Zhang and J.R. Weertman, Acta Mater 2006, vol. 54, pp. 3307-20.

T.B. Tengen, T. Wejrzanowski, R. Iwankiewicz and K.J. Kurzydlowski, Solid State Phenom 2008, vol. 140, pp. 185-90.

P. Blikstrin and A.P. Tschiptschin, Materials Research 1999, vol. 2, pp. 133-37.

X.Y. Song, G.Q. Liu and N.J. Gu, Scripta Mater 2000, vol. 43, pp. 355-59.

M.W. Nordbakke, N. Ryum and O. Hunderi, Acta Mater 2002, vol. 50, pp. 3661-70.

K. Marthinsen, O. Hunderi and N. Ryum, Acta Mater 1996, vol. 44, pp. 1681-89.

F. Wakai, N. Enomoto and H. Ogawa, Acta Mater 2000, vol. 48, pp. 1297-311.

H.J. Frost and C.V. Thompson, Curr Opin Solid St M 1996, vol. 1, pp. 361-68.

W. Fayad, C.V. Thompson and H.J. Frost, Scripta Mater 1999, vol. 40, pp. 1199-204.

D. Weygand, Y. Bréchet, J. Lépinoux and W. Gust, Philos Mag B 1999, vol. 79, pp. 703-16.

Y. Liu, T. Baudin and R. Penelle, Scripta Mater 1996, vol. 34, pp. 1679-83.

S. Raghavan and S.S. Sahay, Mater Sci Eng, A 2007, vol. 445-446, pp. 203-09.

C.E. Krill III and L.Q. Chen, Acta Mater 2002, vol. 50, pp. 3059-75.

S.G. Kim, D.I. Kim, W.T. Kim, and Y.B. Park: Phys. Rev. E, 2006, vol. 74, art. no. 061605.

R. Darvishi Kamachali and I. Steinbach, Acta Mater 2012, vol. 60, pp. 2719-28.

Z.R. Luo, C.J. Lu and Y.J. Gao, Guangxi Sci. 2016, vol. 23, pp. 432-36.

V. Yadav, L. Vanherpe and N. Moelans, Comput Mater Sci 2016, vol. 125, pp. 297-308.

K. Chang, L.Q. Chen, C.E.K. Iii and N. Moelans, Comput Mater Sci 2017, vol. 127, pp. 67-77.

E. Miyoshi, T. Takaki, M. Ohno, Y. Shibuta, S. Sakane, T. Shimokawabe, and T. Aoki: NPJ Comput. Mater., 2017, vol. 3, art. no. 25.

V. Yadav and N. Moelans, Scripta Mater 2018, vol. 142, pp. 148-52.

W.E. Benson and J.A. Wert, Acta Mater 1998, vol. 46, pp. 5323-33.

R. Heilbronner, J Struct Geol 2000, vol. 22, pp. 969-81.

I. Steinbach: Modell. Simul. Mater. Sci. Eng., 2009, vol. 17, art. no. 073001.

N. Warnken, D. Ma, A. Drevermann, R.C. Reed, S.G. Fries and I. Steinbach, Acta Mater 2009, vol. 57, pp. 5862-75.

N. Ta, L.J. Zhang, Y. Tang, W.M. Chen and Y. Du, Surf Coat Technol 2015, vol. 261, pp. 364-74.

M. Wei, Y. Tang, L.J. Zhang, W.H. Sun and Y. Du, Metall Mater Trans A 2015, vol. 46, pp. 3182-91.

K. Wang, M. Wei, L.J. Zhang and Y. Du, Metall Mater Trans A 2016, vol. 47, pp. 1510-16.

K. Wang, M. Wei, and L.J. Zhang: Materials, 2016, vol. 9, art. no. 584.

J.E. Burke and D. Turnbull, Prog Met Phys 1952, vol. 3, pp. 220-92.

W.W. Mullins, J Appl Phys 1956, vol. 27, p. 900-04.

J. Von Neumann, American Society for Metals, Cleveland 1952, pp. 108–10.

M. Hillert, Acta Mater 1965, vol. 13, p. 227-38.

MICRESS: The MICRostructure Evolution Simulation Software. http://www.micress.de. Accessed 27 May 2018.

I. Steinbach and F. Pezzolla, Physica D 1999, vol. 134, pp. 385-93.

K. Lee. PhD Dissertation. Maryland: University of Maryland College Park, 2004.

K. Lee and W. Losert, Acta Mater 2005, vol. 53, pp. 3503-10.

N. Maraşlı, K. Keşlıoğlu and B. Arslan, J Cryst Growth 2003, vol. 247, pp. 613-22.

Y. He, H. Ding, L. Liu and K. Shin, Mater Sci Eng, A 2006, vol. 429, pp. 236-46.

ImageJ: Image Processing and Analysis in Java. https://imagej.nih.gov/ij. Accessed 27 May 2018.

T. Wejrzanowski and K.J. Kurzydlowski, Solid State Phenom 2005, vol. 101-102, pp. 315-18.

P.R. Rios and K. Lucke, Scripta Mater 2001, vol. 44, p. 2471.

G.W. Yang, X.J. Sun, Q.L. Yong, Z.D. Li and X.X. Li, J Iron Steel Res Int 2014, vol. 21, pp. 757-64.

S.S. Zhang, M.Q. Li, Y.G. Liu, J. Luo and T.Q. Liu, Mater Sci Eng, A 2011, vol. 528, pp. 4967-72.

H.S. Zurob, C.R. Hutchinson, Y. Brechet and G. Purdy, Acta Mater 2002, vol. 50, pp. 3077-94.

V.E. Fradkov, Philos Mag Lett 1988, vol. 58, pp. 271-75.

E.D. Hondros, Proc R Soc London, Ser A 1965, vol. 286, pp. 479-98.

Acknowledgments

The financial support from the National Key Research and Development Program of China (Grant No. 2016YFB0301101) and the National Natural Science Foundation of China (Grant No. 51474239) is acknowledged. Lijun Zhang acknowledges financial support from the project supported by State Key Laboratory of Powder Metallurgy Foundation, Central South University, Changsha, P. R. China. The authors wish to thank Dr. Z. Lu from School of Materials Science and Engineering, Guilin University of Electronic Technology, Guilin, Guangxi, P.R. China for discussions on the effect of the boundary condition on the grain growth simulation during the revision of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 5, 2018.

Rights and permissions

About this article

Cite this article

Gao, J., Wei, M., Zhang, L. et al. Effect of Different Initial Structures on the Simulation of Microstructure Evolution During Normal Grain Growth via Phase-Field Modeling. Metall Mater Trans A 49, 6442–6456 (2018). https://doi.org/10.1007/s11661-018-4908-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4908-5