Abstract

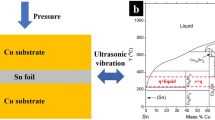

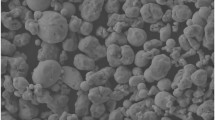

In this study, the microstructure and mechanical properties of Cu6Sn5 and Cu3Sn intermetallic joints, formed by the transient liquid phase (TLP) soldering process with and without the assistance of ultrasonic waves (USWs), were compared. After the application of USWs in the TLP soldering process, Cu-Sn intermetallic compounds (IMCs) exhibited a novel noninterfacial growth pattern in the molten solder interlayer. The resulting Cu6Sn5 and Cu3Sn joints consisted of refined equiaxed IMC grains with average sizes of 3 and 2.3 µm, respectively. The Cu6Sn5 grains in the ultrasonically soldered intermetallic joints demonstrated uniform mechanical properties with elastic modulus and hardness values of 123.0 and 5.98 GPa, respectively, while those of Cu3Sn grains were 133.9 and 5.08 GPa, respectively. The shear strengths of ultrasonically soldered Cu6Sn5 and Cu3Sn joints were measured to be 60 and 65 MPa, respectively, higher than that for reflow-soldered intermetallic joints. Ultrasonically soldered Cu6Sn5 and Cu3Sn joints both exhibited a combination of transgranular and intergranular fractures during shear testing.

Similar content being viewed by others

References

F.P. Carson, Y.C. Kim, and I.S. Yoon: Proc. IEEE, 2009, vol. 97, pp. 31-42.

H.Y. Hsiao, C.M. Liu, H.W. Lin, T.C. Liu, C.L. Lu, Y.S. Huang, C. Chen, and K. Tu: Science, 2012, vol. 336, pp. 1007-1010.

Y.J. Chang, C.T. Ko, and K.N. Chen: IEEE Electron. Device Lett., 2013, vol. 34, pp. 102-104.

Y. Lv, M. Chen, M. Cai, and S. Liu: Semicond. Sci. Tech., 2014, vol. 29, pp. 25003-25009.

W. Zhang and W. Ruythooren: J. Electron. Mater., 2008, vol. 37, pp. 1095-1101.

J.F. Li, P.A. Agyakwa, and C.M. Johnson: Acta Mater., 2010, vol. 58, pp. 3429-3443.

N.S. Bosco and F.W. Zok: Acta Mater., 2004, vol. 52, pp. 2965-2972.

G.O. Cook and C.D. Sorensen: J. Mater. Sci., 2011, vol. 46, pp. 5305-5323.

B. Liu, Y. Tian, J. Feng, and C. Wang: J. Mater. Sci., 2016, vol. 52, pp. 1-12.

B. Liu, Y. Tian, C. Wang, R. An, and C. Wang: Intermetallics, 2017, vol. 80, pp. 26-32.

B. Liu, Y. Tian, C. Wang, R. An, and Y. Liu: J. Alloys Compd., 2016, vol. 687, pp. 667-673.

J.F. Li, P.A. Agyakwa, and C.M. Johnson: Acta Mater., 2011, vol. 59, pp. 1198-1211.

M. Li, Z. Li, Y. Xiao, and C. Wang: Appl. Phys. Lett., 2013, vol. 102, pp. 094104.

Z.L. Li, H.J. Dong, X.G. Song, H.Y. Zhao, J.C. Feng, J.H. Liu, H. Tian, and S.J. Wang: Ultrason. Sonochem., 2017, vol. 36, pp. 420-426.

H. Ji, Y. Qiao, and M. Li: Scr. Mater., 2015, vol. 110, pp. 19-23.

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A.Venkatesh, and S. Suresh: Acta Mater., 2001, vol. 49, pp. 3899-3918.

R. Zhang, Y. Tian, C. Hang, B. Liu, and C. Wang: Mater. Lett., 2013, vol. 110, pp. 137-140.

M. Virot, T. Chave, S.I. Nikitenko, D.G. Shchukin, T. Zemb, and H. Mohwald: J. Phys. Chem. C, 1974, vol. 114, pp. 13083-13091.

K.S. Suslick, D.A. Hammerton, and R.E. Cline: J. Am. Chem. Soc., 1986, vol. 89, 5641-5642.

A. Karimi and J.L. Martin: Int. Mater. Rev., 1985, vol. 31, pp. 219-224.

T. Hyeon, K. Kolbeck, W. Mcnamara, and M. Mdleleni: Philos. Trans. R. Soc. B, 1999, vol. 357, pp. 335.

Z. Li, M. Li, Y. Xiao, and C. Wang: Ultrason. Sonochem., 2014, vol. 21, pp. 924-929.

X. Chen, J. Yan, F. Gao, J. Wei, Z. Xu, and G. Fan: Ultrason. Sonochem., 2013, vol. 20, pp. 144-154.

R.K. Chinnam, C. Fauteux, J. Neuenschwander, and J. Janczak-Rusch: Acta Mater., 2011, vol. 59, pp. 1474-1481.

C. Hang, Y. Tian, and R. Zhang: J. Mater. Sci: Mater. Electron., 2013, vol. 24, pp. 3905-3913.

S.F. Choudhury and L. Ladani: J. Electron. Mater., 2014, vol. 43, pp. 996-1004.

P.F. Yang, Y.S. Lai, S.R. Jian, J. Chen, and R.S. Chen: Mater. Sci. Eng. A, 2008, vol. 485, pp. 305-310.

D. Mu, H. Huang, and K. Nogita: Mater. Lett., 2012, vol. 86, pp. 46-49.

D. Mu, H. Huang, S.D. Mcdonald, J. Read, and K. Nogita: Mater. Sci. Eng. A, 2013, vol. 566, pp. 126-133.

X. Deng, N. Chawla, K.K. Chawla, and M. Koopman: Acta Mater., 2004, vol. 52, pp. 4291–303.

C. Lee, P. Wang, and J. Kim: 57th Electron. Compo. Technol. Conf. (ECTC 2007), 2007, pp. 648–52.

N. Hansen: Scr. Mater., 2004, vol. 51, pp. 801-806.

N. Hansen: Mater. Sci. Eng. A, 2005, vol. 409, pp. 39-45.

K. Chu, Y. Sohn, and C. Moon: Scr. Mater., 2015, vol. 109, pp. 113-117.

C. Yang, F. Le, and S. W. Ricky Lee: Microelectron. Reliab., 2016, vol. 62, pp. 130-140.

Acknowledgments

This research is sponsored by the Shandong Provincial Natural Science Foundation of China (ZR2016EEQ12), the Researching Innovation Fund of Harbin Institute of Technology (HIT. NSRIF. 2016091), the National Natural Science Foundation of China (Grant Nos. 51405099 and U1537206), the Shanghai Aerospace Innovation Fund (Grant No. SAST 2015045), and the National Science and Technology Major Project (No. 2014ZX04001131).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted December 14, 2017.

Rights and permissions

About this article

Cite this article

Zhao, H.Y., Liu, J.H., Li, Z.L. et al. A Comparative Study on the Microstructure and Mechanical Properties of Cu6Sn5 and Cu3Sn Joints Formed by TLP Soldering With/Without the Assistance of Ultrasonic Waves. Metall Mater Trans A 49, 2739–2749 (2018). https://doi.org/10.1007/s11661-018-4664-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4664-6