Abstract

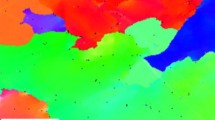

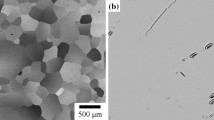

The microstructural and high-temperature mechanical properties of Fe–26Al–xNb (x = 3 and 5 at. pct) are compared. The alloys were investigated “as cast” and after hot rolling at 1473 K (1200 °C). Scanning electron microscopes equipped with EDS and EBSD were used for the microstructure and phase identification. The addition of 3 at. pct of Nb into the Fe3Al matrix leads to the formation of C14 λ—Laves phase (Fe,Al)2Nb (LP) particles spread in the Fe3Al matrix, while an eutectic with thin lamellae of LP C14 λ—Laves phase (Fe,Al)2Nb and matrix is also formed in the iron aluminide with 5 at. pct of Nb. The presence of incoherent precipitates is connected with the enhancement of the high-temperature strength and creep resistance.

Similar content being viewed by others

References

C. G. McKamey: Physical Metallurgy and Processing of Intermetallic Compounds, 1994, Springer, Boston, pp. 351 – 391.

[2] N. S. Stoloff: Materials Science and Engineering A258, 1998, pp. 1 – 14.

[3] S. C. Deevi, V. K. Sikka: Intermetallics 4, 1996, pp. 357 – 375.

[4] M. Palm: Intermetallics 13, 2005, pp. 1286 – 1295.

M. Palm, A. Schneider, F. Stein, and G. Sauthoff: Mater. Res. Soc. Symp. Proc., Vol. 842, 2005, S1.7.1–S1.7.12.

P. Kejzlar, P. Kratochvíl, R. Král, V. Vodičková: Metall. Mater. Trans. A. 2014, 45(1), 335–342.

[7] P. Kratochvíl, P. Kejzlar, R. Král, V. Vodičková: Intermetallics 20, 2012, pp. 39 – 46.

P. Kratochvíl, M. Švec, V. Vodičková: Metall. Mater. Trans. A 48, 2017, 4093–4096.

[9] O. Prymak, F. Stein: Intermetallics 18, 2010, pp. 1322 –1326.

Morris DG, Muñoz-Morris MA.: Intermetallics. 2012;23:169-76

D. M. Dimiduk, M. G. Mendiratta, D. Banerjee, H. A. Lipsitt: Acta Metallurgica, 36, 2947–58, 1988.

M. Palm: J. Alloys Compd. 2009, 475(1–2), 173–177.

V. Raghavan: Journal of Phase Equilibria and Diffusion, 27, 284–287, 2006.

J. Čadek: Creep in Metallic Materials. Academia, Prague 1988.

O. D. Sherby, J. Wertman: Acta Metall., 1979, 27, 387-400.

C. Herring: J. Appl. Phys. 21, 1950, 437.

F. R. N. Nabarro: Reports on Conference on Strength of Solids, The Physical Society, London, 1948, pp. 75.

Acknowledgments

The research was supported by the Grant Agency of the Czech Republik through the Project No. 16-05608S and with the support of the Institutional Endowment for the Long Term Conceptual Development of Research Institutes (at the Technical University of Liberec), as provided by the Ministry of Education, Youth and Sports of the Czech Republic in the year 2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 10, 2017.

Rights and permissions

About this article

Cite this article

Kratochvíl, P., Švec, M., Král, R. et al. The Effect of Nb Addition on the Microstructure and the High-Temperature Strength of Fe3Al Aluminide. Metall Mater Trans A 49, 1598–1603 (2018). https://doi.org/10.1007/s11661-018-4524-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4524-4