Abstract

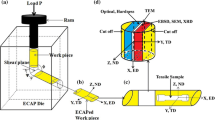

The low-carbon steel workpieces are deformed by equal-channel angular pressing at 293 K (20 °C) up to an equivalent strain of ~12 using route B c, which results in the bulk ultrafine-grained (UFG) structure with high dislocation density and partial dissolution of cementite. The yield strength (YS) is enhanced from 208 (as-received) to 872 MPa and the tensile strength is increased from 362 to 996 MPa, but the material loses total elongation (TE) from 36.2 to 2.9 pct. Cold rolling of equal-channel angular pressed steel produces the refined structure of grain size 0.11 μm. The YS increases further to 924 MPa with a marginal gain in ductility due to the reappearance of the γ fiber component. Flash annealing the samples, which were equal-channel angular pressed followed by cold rolling, at 873 K (600 °C) results in 27 pct of micron-sized (9 µm) ferrite grains in submicron-sized (<1 µm) matrix with a reduced defect density and small amount of precipitation of cementite. TE increases from 2.9 to 23.3 pct. The material retains a YS of 484 MPa and tensile strength of 517 MPa, which are higher than those of the as-received material. The UFG grains are failed by cleavage, but the micron-sized grains display ductile fracture. The ductility of the flash-annealed material is recovered significantly due to bimodal grain size distribution in ferrite and the development of a good amount of γ fiber texture components. The major contribution toward recovery of ductility comes from the bimodal grain size distribution in ferrite rather the precipitation of cementite.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Progr. Mater. Sci., 2000, vol. 45, pp. 103–89.

A.A. Karimpoor, U. Erb, K.T. Aust, and G. Palumbo: Scripta Mater., 2003, vol. 49, pp. 651–56.

K.T. Park and D.H. Shin: Mater. Sci. Eng. A, 2002, vol. 334, pp. 79–86.

C.C. Koch: Scripta Mater., 2003, vol. 49, pp. 657–62.

W.D. Callister, Jr.: Materials Science and Engineering—An Introduction, 6th ed., John Wiley & Sons, Inc., New York, NY, 2004, pp. 346–84.

R.Z. Valiev and T.G. Langdon: Progr. Mater. Sci., 2006, vol. 51, pp. 881–98.

L.S. Toth and C. Gu: Mater. Charact., 2014, vol. 92, pp. 1–14.

J.T. Wang, C. Xu, Z.Z. Du, G.Z. Qu, and T.G. Langdon: Mater. Sci. Eng. A, 2005, vols. 410–411, pp. 312–15.

D.H. Shin, J. Kim, and K.T. Park: Met. Mater. Int., 2001, vol. 7 (5), pp. 431–35.

L. Kraus, J. Zrnik, M. Fujda, and M. Cieslar: Grain Refinement of Low Carbon Steel by ECAP Severe Plastic Deformation, Nanocon 2011, Brno, Czech Republic, European Union, 2011.

Y. Fukuda, K. Oh-ishi, Z. Horita, and T.G. Langdon: Acta Mater., 2002, vol. 50, pp. 1359–68.

G.G. Maier, E.G. Astafurova, H.J. Maier, E.V. Naydenkin, G.I. Raab, P.D. Odessky, and S.V. Dobatkin: Mater. Sci. Eng. A, 2013, vol. 581, pp. 104–07.

R. Manna, N.K. Mukhopadhyay, and G.V.S. Sastry: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1525–34.

L.G. Kornelyuk, A.Y. Lozovoi, and I.M. Razumovskii: Phil. Mag. A, 1998, vol. 77 (2), pp. 465–74.

R. Manna, N.K. Mukhopadhyay, and G.V.S. Sastry: Mater. Sci. Forum, 2012, vol. 710, pp. 241–46.

S. Patra, Sk.Md. Hasan, N. Narasaiah, and D. Chakrabarti: Mater. Sci. Eng. A, 2012, vol. 538, pp. 145–55.

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Matlock: Mater. Sci. Eng. A, 2006, vol. 441, pp. 1–17.

D. Jia, Y.M. Wang, K.T. Ramesh, E. Ma, Y.T. Zhu, and R.Z. Valiev: Appl. Phys. Lett., 2001, vol. 79, pp. 611–13.

Y.M. Wang, M.W. Chen, F. Zhou, and E. Ma: Nature (London), 2002, vol. 419, pp. 912–14.

J.R. Weertman: in Nanostructured Materials: Processing, Properties and Applications, C.C. Koch, ed., William Andrews Publishing, Norwich, 2002, p. 397.

F. Khodabakhshi and M. Kazeminezhad: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5212–18.

G.E. Dieter: Mechanical Metallurgy, 2nd ed., McGraw-Hill Book Co., New York, NY, 1988, pp. 185–240.

Y. Estrin and A. Vinogradov: Acta Mater., 2013, vol. 61, pp. 782–817.

Y.M. Wang and E. Ma: Acta Mater., 2004, vol. 52, pp. 1699–1709.

E. Ma: JOM, 2006, pp. 5849–53.

T.S. Wang, Z. Li, B. Zhang, X.J. Zhang, J.M. Deng, and F.C. Zhang: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2798–2801.

H.W. Park and J. Yanagimoto: Mater. Sci. Eng. A, 2013, vol. 567 pp. 29–37.

A. Karmakar, A. Karani, S. Patra, and D. Chakrabarti: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2041–52.

E. Ma: Scripta Mater., 2003, vol. 49, pp. 663–68.

J.J. Zheng, C.S. Li, S. He, B. Cai, and Y.L. Song: Mater. Sci. Eng. A, 2016, vol. 670, pp. 275–79.

N. Phoumiphon, R. Othman, and A.B. Ismail: Procedia Chem., 2016, vol. 19, pp. 822–27.

D.H. Shin and K.T. Park: Mater. Sci. Eng. A, 2005, vols. 410–411, pp. 299–302.

S.M. Hosseini, M. Alishahi, A. Najafizadeh, and A. Kermanpur: Mater. Lett., 2012, vol. 74, pp. 206–08.

B.R. Kumar, S. Sharma, and B. Mahato: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2209–16.

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon: Scripta Mater., 1996, vol. 35, pp. 143–46.

P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1989–97.

G.R. Stibitz: Phys. Rev., 1936, vol. 49, p. 859.

S.S. Hazra, A.A. Gazder, and E.V. Pereloma: Mater. Sci. Eng. A, 2009, vol. 524, pp. 158–67.

A. Borbely, J.H. Driver, and T. Ungar: Acta Mater., 2000, vol. 48, pp. 2005–16.

H.P. Klug and L.E. Alexander: X-Ray Diffraction Procedures for Polycrystalline and Amorphous Materials, John Wiley, New York, NY, 1954, pp. 491–94.

G.K. Williamson and R.E. Smallman: Phil. Mag., 1956, vol. 1, pp. 34–46.

R.E. Smallman and K.H. Westmacott: Phil. Mag., 1957, vol. 2, pp. 669–83.

K. Zhang, I.V. Alexandrov, A.R. Kilmametovz, R.Z. Valievz, and K. Luy: J. Phys. D: Appl. Phys., 1997, vol. 30, pp. 3008–15.

S.S. Hazra, A.A. Gazder, A. Carman, and E.V. Pereloma: Min. Met. Mater. Soc. ASM Int., 2010, pp. 1334–48.

D.H. Shin, B.C. Kim, Y.S. Kim, and K.T. Park: Acta Mater., 2000, vol. 48, pp. 2247–55.

D.H. Shin, I. Kim, J. Kim, and K.T. Park: Acta Mater., 2001, vol. 49, pp. 1285–92.

R. Singh, S. Kumar, N.K. Mukhopadhyay, G.V.S. Sastry, and R. Manna: Int. J. Met. Eng., 2013, vol. 2 (1), pp. 62–68.

R. Manna, N.K. Mukhopadhyay, and G.V.S. Sastry: Scripta Mater., 2005, vol. 53, pp. 1357–61.

R. Manna, N.K. Mukhopadhyay, and G.V.S. Sastry: Proc. 30th Risø Int. Symp on Materials Science: Nanostructured Metals—Fundamentals to Applications, J.-C. Grivel et al., eds., Risø National Laboratory for Sustainable Energy, T.U.D., Roskilde, Denmark, Sept. 7–11, 2009, pp. 245–52.

Y.T. Zhu and T.C. Lowe: Mater. Sci. Eng. A, 2000, vol. 291, pp. 46–53.

D. Verma, N.K. Mukhopadhyay, G.V.S. Sastry, and R. Manna: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1803–17.

P.B. Prangnell, J.R. Bowen, and P.J. Apps: Mater. Sci. Eng. A, 2004, vols. 375–377, pp. 178–85.

T. Hebesberger, H.P. Stüwe, A. Vorhauer, F. Wetscher, and R. Pippan: Acta Mater., 2005, vol. 53, pp. 393–402.

H. Jazaeri, F.J. Humphreys, and S.P. Bate: Mater. Sci. Forum, 2006, vol. 153, pp. 519–21.

P.B. Prangnell, Y. Huang, M. Berta, and P.J. Apps: Proc. Int. Symp. on Fundamentals of Deformation and Annealing, P.B. Prangnell and P.S. Bate, eds., Trans Tech, Zurich, 2007.

H. Jazaeri and F.J. Humphreys: Acta Mater., 2004, vol. 52, pp. 3239–50.

Yuntian Zhu and Terence G. Langdon: JOM, 2004, vol. 56, pp. 58–63.

F. Khodabakhshi and M. Kazeminezhad: Mater. Des., 2011, vol. 32, pp. 3280–86.

Kyung-Tae Park, Yong-Seog Kim, Jung Guk Lee, and Dong Hyuk Shin: Mater. Sci. Eng. A, 2000, vol. 293, pp. 165–72.

J. Hodowany, G. Ravichandran, A.J. Rosakis, and P. Rosakis: Exp. Mech., 2000, vol. 40, pp. 113–23.

G. Purcek, O. Saray, M.I. Nagimov, A.A. Nazarov, I.M. Safarov, V.N. Danilenko, O.R. Valiakhmetov, and R.R. Mulyukov: Phil. Mag., 2012, vol. 92 (6), pp. 690–704.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 1st ed., Pergamon, New York, NY, 1995, pp. 369–78.

S. Berbenni, V. Favier, and M. Berveiller: Int. J. Plasticity, 2007, vol. 23, pp. 114–42.

D.H. Shin, W.G. Kim, J.Y. Ahn, K.T. Park, and N.J. Kim: La Metall. Ital., 2006, vol. 5, pp. 49–54.

Stephen D. Antolovich and Ronald W. Armstrong: Progr. Mater. Sci., 2014, vol. 59, pp. 1–160.

P. Zhang, S.X. Li, and Z.F. Zhang: Mater. Sci. Eng. A, 2011, vol. 529, pp. 62–73.

V.G. Gavriljuk: Mater. Sci. Eng. A, 2003, vol. 345, pp. 81–89.

C. Borchersa, T. Al-Kassaba, S. Gotoa, and R. Kirchheim: Mater. Sci. Eng. A, 2009, vol. 502, pp. 131–38.

Y.J. Li, P. Choi, C. Borchers, S. Westerkamp, S. Goto, D. Raabe, and R. Kirchheim: Acta Mater., 2011, vol. 59, pp. 3965–77.

Y. Ivanisenko, W. Lojkowski, R.Z. Valiev, and H.-J. Fecht: Acta Mater., 2003, vol. 51, pp. 5555–70.

Y.V. Ivanisenko1’, R.Z. Valiev, W. Lojkowski, A. Grob, and H.-J. Fecht: in Ultrafine-Grained Materials II, Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.S. Lowe, eds., TMS, Seattle, WA, 2002, p. 17.

Y. Ivanisenko, R.K. Wunderlich, R.Z. Valiev, and H.J. Fecht: Scripta Mater., 2003, vol. 49, pp. 947–52.

K.T. Park, C.S. Lee, and D.H. Shin: Rev. Adv. Mater. Sci., 2005, vol. 10, pp 133–37.

J.R. Tarpani, M.H.P. Braz, W.W. Bose Filho, and D. Spinelli: Mater. Res., 2002, vol. 5, pp. 357–64.

I.M. Safarov, A.V. Korznikov, R.M. Galeev, S.N. Sergeev, S.V. Gladkovskii, E.M. Borodin, and I.Y. Pyshmintsev: Phys. Met. Metallogr., 2014, vol. 115, pp. 295–302.

N. Tsuji, S. Okuno, Y. Koizumi, and Y. Minamino: Mater. Trans., 2004, vol. 45, pp. 2272–81.

J.I. Leinonen: Acta Polytech., 2004, vol. 44, pp. 37–40.

A. Haldar, S. Suwas, and D.M. Bhattacharjee: Texture in Steels, Springer, New York, NY, 2009, pp. 185–205.

R.K. Ray, J.J. Jonas, and R.E. Hook: Int. Mater. Rev., 1994, vol. 39 (4), pp. 129–72.

Pei He: On the Structure-Property Correlation and the Evolution of Nanofeatures in 12-13.5 pct Cr Oxide Dispersion Strengthened Ferritic Steels, KIT Scientific Publishing, 2013, vol. 31, p. 152.

Acknowledgments

The authors thank the Department of Science and Technology, the Government of India, for the financial support under Project No. SR/S3/ME/0009/2010 (G) dated July 14, 2011. They also gratefully acknowledge the help of Professor I. Samajdar, Indian Institute of Technology Bombay, for extending the OIM facility supported by the Intensification of Research in High Priority Areas of DST, New Delhi, and the X-ray diffraction facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 28 2016.

Rights and permissions

About this article

Cite this article

Singh, R.B., Mukhopadhyay, N.K., Sastry, G.V.S. et al. Recovery of Ductility in Ultrafine-Grained Low-Carbon Steel Processed Through Equal-Channel Angular Pressing Followed by Cold Rolling and Flash Annealing. Metall Mater Trans A 48, 1189–1203 (2017). https://doi.org/10.1007/s11661-016-3892-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3892-x