Abstract

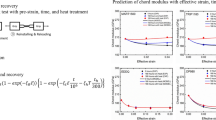

Transformation-induced plasticity (TRIP) steel might have a high energy-absorption characteristic because it could possibly consume impact energy by not only plastic deformation but also strain-induced martensitic transformation (SIMT) during deformation. Therefore, TRIP steel is considered to be suitable for automotive structures from the viewpoint of safety. Bending deformation due to buckling is one of the major collapse modes of automotive structures. Thus, an investigation on the bending deformation behavior and energy-absorption characteristic in TRIP steel at high deformation rate is indispensable to clarify the mechanism of better performance. Some past studies have focused on the improvement of mechanical properties by means of SIMT; however, the mechanism through which the energy-absorption characteristic in steel can be improved is still unclear. In this study, the three-point bending deformation behavior of a beam specimen made of type-304 austenitic stainless steel, a kind of TRIP steel, is investigated at various deflection rates by experiments and finite-element simulations based on a constitutive model proposed by one of the authors. After confirming the validity of the computation, the rate-sensitivity of energy absorption from the viewpoint of hardening behavior is examined and the improvement of the energy-absorption characteristic in TRIP steel including its mechanism is discussed.

Similar content being viewed by others

References

F.D. Fischer, G. Reisner, E. Werner, K. Tanaka, G. Cailletaud, and T. Antretter: Int. J. Plast., 2000, Vol. 16, pp. 723–748.

T. Iwamoto, T. Tsuta, and Y. Tomita: Int. J. Mech. Sci., 1998, vol. 40, pp. 173–182.

A. Khan, M. Baig, S. Choi, H. Yang, and X. Sun: Int. J. Plast., 2012, vol. 30-31, pp. 1–17.

R. Mahnken, A. Schneidt, and T. Antretter: Int. J. Plast., 2009, vol. 25, pp. 183–204.

A. Rusinek, J.A. Rodríguez-Martínez, R. Pesci, and J. Capelle: J. Theor. Appl. Mech., 2010, vol. 48, pp. 1027–1042.

I. Tamura: Met. Sci., 1982, vol. 16, pp. 245–253.

Y. Tomita and T. Iwamoto: Int. J. Mech. Sci., 1995, vol. 37, pp. 1295–1305.

R. Zaera, J.A. Rodríguez-Martínez, .A. Casado, J. Fernández-Sáez, A. Rusinek, and R. Pesci: Int. J. Plast., 2012, vol. 29, pp. 77–101.

R. Zaera, R.A Rodríguez-Martínez, and D. Rittel: Int. J. Plast., 2013, vol. 40, pp. 185–201.

H. Huh, S.B. Kim, J.H. Song, J.H. Lim: Int. J. Mech. Sci., 2008, vol. 50, pp. 918-931.

J. Huh, H. Huh, and C.S. Lee: Int. J. Plast., 2013, vol. 44, pp. 23–46.

L. Durrenberger, D. Even, A. Molinari, and A. Rusinek: J. Phys. IV., 2006, vol. 134, pp. 1287–1293.

J.A. Nemes and J. Eftis: Int. J. Plast., 1993, vol. 9, pp. 243–270.

T. Rong, L. Lin, B.C. De Cooman, W. Xi-chen, and S. Peng: ISIJ Int., 2006, vol. 13, pp. 51–56.

S. Curtze, V.T. Kuokkala, M. Hokka, and P. Peura: Mater. Sci. Eng. A, 2009, vol. 507, pp. 124–131.

J.A. Rodríguez-Martínez, R. Pesci, and A. Rusinek: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5974–5982.

J.A. Rodríguez-Martínez, A. Rusinek, R. Pesci, and R. Zaera: Int. J. Solids Struct., 2013, vol. 2, pp. 339–351.

R. Zaera, J.A. Rodríguez-Martínez, G. Vadillo, and J. Fernández-Sáez: J. Mech. Phys. Solids, 2014, vol. 64, pp. 316–337.

T. Iwamoto and T. Tsuta: Int. J. Plast., 2002, vol. 18, pp. 1583–1606.

Y. Chuman, K. Minuras, K. Kaizu, and S. Tanimura: Int. J. Impact Eng., 1997, vol. 19, pp. 165–174.

T. Yokoyama, K. Kishida: Exp. Mech., 1989, vol. 29, pp. 188–194.

Y. Tomita and T. Iwamoto: Int. J. Mech. Sci., 2001, vol. 43, pp. 2017–2034.

G.B. Olson and M. Cohen: Metall. Trans. A., 1975, vol. 6A, pp. 791–795.

R.G. Stringfellow, D.M. Parks, and G.B. Olson: Acta Metall. Mater., 1992, vol. 40, pp. 1703–1716.

T. Iwamoto, M. Cherkaoui, and T. Sawa: Int. J. Mod. Phys. B, 2008, vol. 22, pp. 5985–5990.

T. Iwamoto and T. Tsuta: Int. J. Plast., 2000, vol. 16, pp. 791–804.

T. Iwamoto, T. Kawagishi, T. Tsuta, S. Morita: JSME Int. J. Ser. A, 2001, vol. 44, pp. 443–452.

T. Iwamoto: Int. J. Plast., 2004, vol. 20, pp. 841–869.

T. Iwamoto and T. Tsuta: Key Eng. Mater., 2004, vol. 274–276, pp. 679–684.

Y. Tomita and Y. Shibutani: Int. J. Plast., 2000, vol. 16, pp. 769–789.

R.F. Kubler, M. Berveiller, and P. Buessler: Int. J. Plast., 2011, vol. 27, pp. 299–327.

M. Fischlschweiger, G. Cailletaud, and T. Antretter: Int. J. Plast., 2012, vol. 37, pp. 53–71.

D. Peirce, C.F. Shih, A. Needleman: Composite Struct., 1984, vol. 118, pp. 875–887.

J.D. Eshelby: Proc. R. Soc. Lond., 1957, vol. A241, pp. 376–396.

J. Talonen: Effect of Strain-Induced α′-Martensite Transformation on Mechanical Properties of Metastable Austenitic Stainless Steels. Doctoral Dissertation, Helsinki University of Technology, 2007.

Acknowledgment

We wish to thank Mr. Hashimoto of Webast Japan Corporation and Ms. Shi of Ondo Corporation for their assistance with the experimental investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 20, 2016.

Appendix A: Derivation of Eq. [7]

Appendix A: Derivation of Eq. [7]

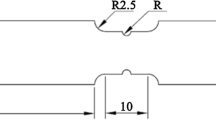

The maximum bending strain in the case of small deformation is calculated in the case that the shape of the deformed specimen is assumed to be an arc as,

where ε is bending strain; L is span length; ∆L is the change in length at the lower surface of specimen, h is the height of specimen; ρ is radius of curvature as shown in Figure A1. With the curvature is assumed to be constant in the entire region of the deformed beam, ρ can be calculated as

where δ is the deflection. (δ/L)2 is considered to be quite small and can be neglected. Thus, we can obtain the following equation,

From Eqs. [A1] and [A3], the normalized deflection is calculated as

Rights and permissions

About this article

Cite this article

Pham, H.T., Iwamoto, T. A Computational Investigation on Bending Deformation Behavior at Various Deflection Rates for Enhancement of Absorbable Energy in TRIP Steel. Metall Mater Trans A 47, 3897–3911 (2016). https://doi.org/10.1007/s11661-016-3565-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3565-9