Abstract

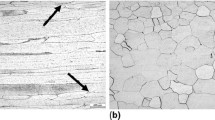

Decreasing thickness and optimizing texture are the two critical means to improve the magnetic properties of high-silicon electrical steel sheet. In the present study, the 0.15-mm-thick Fe-6.5 wt pct Si thin sheets were produced by two-stage cold rolling process with intermediate annealing. The effects of intermediate microstructure on recrystallization texture were investigated using X-ray diffraction and electron backscattered diffraction. As the intermediate grain size increases from 40 to 80 μm, the favorable η fiber (〈001〉//RD, rolling direction) is enhanced and harmful γ fiber (〈111〉//ND, normal direction) is weakened after final annealing, and consequently, the magnetic properties are improved evidently. The number and nature of shear bands relative to the grain boundary regions, which are closely related to the intermediate grain size and rolling parameters, are responsible for the recrystallization texture development.

Similar content being viewed by others

References

M. Abe, Y. Takada, T. Murakami, Y. Tanaka, and Y. Mihara: J. Mater. Eng., 1989, vol. 11, pp. 109–16.

T. Yamaji, M. Abe, Y. Takada, K. Okada, and T. Hiratani: J. Magn. Magn. Mater., 1994, vol. 133, pp. 187–89.

M. Baricco, E. Mastrandrea, C. Antonione, B. Viala, J. Degauque, E. Ferrara, and F. Fiorillo: Mater. Sci. Eng., 1997, vols. A226–228, pp. 1025–29.

A.H. Kasama, C. Bolfarini, C.S. Kiminami, and W.J. BottaFilho: Mater. Sci. Eng., 2007, vol. A449–451, pp. 375–77.

Y. Takada, M. Abe, S. Masuda, and J. Inagaki: J. Appl. Phys., 1988, vol. 64 (10), pp. 5367–69.

T. Ros, Y. Houbaert, O. Fischer, and J. Schneider: J. Mater. Process. Technol., 2003, vol. 141, pp. 132–37.

J.L. Liu, Y.H. Sha, F. Zhang, H.P. Yang, and L. Zuo: J. Appl. Phys., 2011, vol. 109, pp. 1–3.

J.L. Liu, Y.H. Sha, F. Zhang, J.C. Li, Y.C. Yao, and L. Zuo: Scripta Mater., 2011, vol. 65 (4), pp. 292–95.

X. S. Fang, Y. F. Liang, F. Ye, and J. P. Lin: J. Appl. Phys., 2012, vol. 111, pp. 1–4.

H.T. Liu, Z.Y. Liu, Y. Sun, F. Gao, and G.D. Wang: Mater. Lett., 2013, vol. 91, pp. 150–53.

H.Z. Liu, H.T. Liu, Z.Y. Liu, H.H. Lu, H.Y. Song, and G.D. Wang: Mater. Charact., 2014, vol. 88, pp. 1–6.

J.T. Park and J.A. Szpunar: Acta Mater., 2003, vol. 51, pp. 3037–51.

K. Murakami, N. Morishige, and K. Ushioda: Mater. Sci. Forum, 2012, vols. 715–716, pp. 158–63.

Y.H. Sha, C. Sun, F. Zhang, D. Patel, X. Chen, S.R. Kalidindi, and L. Zuo: Acta Mater., 2014, vol. 76, pp. 106–17.

Y. Wang, Y.B. Xu, Y.X. Zhang, F. Fang, X. Lu, H.T. Liu, and G.D. Wang: J. Magn. Magn. Mater., 2015, vol. 379, pp. 161–66.

M.R. Barnett and L. Kestens: ISIJ Int., 1999, vol. 39 (9), pp. 923–29.

Y.Y. Tse, G.L. Liu, and B.J. Duggan: Scripta Mater., 2000, vol. 42, pp. 25–30.

M.Z. Quadir and B.J. Duggan: Acta Mater., 2006, vol. 54, pp. 4337–50.

R. K. Ray, J. J. Jonas, and R. E. Hook: Int. Mater. Rev., 1994, vol. 39, pp. 129–72.

M.F. de Campos, F.J.G. Landgraf, R. Takanohashi, F. C. Chagas, I.G.S. Falleiros, G.C. Fronzaglia, and H. Kahn: ISIJ Int., 2004, vol. 44 (3), pp. 591–97.

S. da Costa Paolinelli, M.A. da Cunha, and A.B. Cota: J. Magn. Magn. Mater., 2008, Vol. 320, pp. e641–44.

R.F. de Araujo Cardoso, L. Brandao, and M.A. da Cunha: J. Mater. Res., 2008, vol. 11 (1), pp. 51–55.

J.T. Park and J.A. Szpunar: J. Magn. Magn. Mater., 2009, vol. 321, pp. 1928–32.

S.S.F. de Dafé, S. da Costa Paolinelli, and A.B. Cota: J. Magn. Magn. Mater., 2011, vol. 323, pp. 3234–38.

I. Samajdar, S. Cicale, B. Verlinden, P. Van Houtte, and G. Abbruzzesse: Scripta Mater., 1998, vol. 39 (8), pp. 1083–88.

J.T. Park and J.A. Szpunar: ISIJ Int., 2005, vol. 45, pp. 743–49.

J.L. Bocos, E. Novillo, M.M. Petite, A. Iza-Mendia, and I. Gutierrez: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 827–39.

Y.C. Yao, Y.H. Sha, J.L. Liu, F. Zhang, and L. Zuo: J. Electron. Mater., 2014, vol. 43 (1), pp. 121–25.

K. Verbeken, L. Kestens, and J.J. Jonas: Scripta Mater., 2003, vol. 48, pp. 1457–62.

K.M. Lee, S.Y. Park, M.Y. Huh, J.S. Kim, and O. Engler: J. Magn. Magn. Mater., 2014, vol. 354, pp. 324–32.

Acknowledgments

This work is supported by the National High Technology Research and Development Program of China (Grant No. 2012AA03A505), as well as the National Natural Science Foundation of China (51171042, 51101031), and the Specialized Research Fund for the Doctoral Program of Higher Education (20110042110002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 31, 2015.

Rights and permissions

About this article

Cite this article

Yao, Y., Sha, Y., Liu, J. et al. Texture and Microstructure for Magnetic Properties of Two-Stage Cold-Rolled Fe-6.5 Wt Pct Si Thin Sheets. Metall Mater Trans A 47, 5771–5776 (2016). https://doi.org/10.1007/s11661-015-3057-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3057-3