Abstract

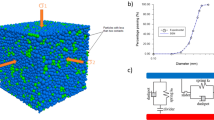

Aluminum- and magnesium-based metal matrix nano-composites with ceramic nano-reinforcements promise low weight with high durability and superior strength, desirable properties in aerospace, automobile, and other applications. However, nano-particle agglomerations lead to adverse effects on final properties: large-size clusters no longer act as dislocation anchors, but instead become defects; the resulting particle distribution will be uneven, leading to inconsistent properties. To prevent agglomeration and to break-up clusters, ultrasonic processing is used via an immersed sonotrode, or alternatively via electromagnetic vibration. A study of the interaction forces holding the nano-particles together shows that the choice of adhesion model significantly affects estimates of break-up force and that simple Stokes drag due to stirring is insufficient to break-up the clusters. The complex interaction of flow and co-joint particles under a high frequency external field (ultrasonic, electromagnetic) is addressed in detail using a discrete-element method code to demonstrate the effect of these fields on de-agglomeration.

Similar content being viewed by others

References

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, J Mater Sci, 26 (1991), 1137-1156

S. Vorozhtsov, D. Eskin, A. Vorozhtsov, and S. Kulkov: in Light Metals 2014, J. Grandfield, ed., TMS, Warrendale, PA, 2014.

J. Tamayo-Ariztondo, S. Madam, E. Djan, D. Eskin, N. Babu, and Z. Fan: in Light Metals 2014, J. Grandfield, ed., TMS, Warrendale, PA, 2014.

Y. Yang, J. Lan and X. Li, “Study on bulk aluminium MMNC fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy” Materials Science and Engineering A, 380(2004), 378–383.

M. Soltani and G. Ahmadi, “On particle adhesion and removal mechanisms in turbulent flow” Journal of Adhesion Science and Technology, 8(7), (1994), 763-785.

R. S. Bradley, “The Cohesive force between Solid Surfaces and the Surface Energy of solids” Phil. Mag. 13(1932), 853–62,

X. Li. Y. Yang, and D. Weiss: in Ultrasonic Cavitation Based Dispersion of Nanoparticles in Aluminum Melts for Solidification Processing of Bulk Aluminum Matrix Nano-composite: Theoretical Study, Fabrication and Characterization, AFS Transactions, American Foundry Society, Schaumburg, IL (2007)

D. Zhang, L. Nastac, J. Mater. Res. Technol., (2015) doi:10.1016/j.jmrt.2014.09.001.

G. Djambazov, V. Bojarevics, B. Lebon, and K. Pericleous: in Light Metals 2014, J. Grandfield, ed., TMS, Warrendale, PA, 2014.

C. Goniva, C. Kloss, A. Hager, G. Wierink, and S. Pirker: 8th International Conference on CFD in Oil & Gas, Metallurgical and Process Industries, SINTEF/NTNU, Trondheim Norway, 21–23 June 2011

A. Hager, C. Kloss, S. Pirker, and C. Goniva: ., “Parallel Resolved Open Source CFD-DEM: Method, Validation and Application” The Journal of Computational Multiphase Flows, 6(1), (2014), 13-27.

Derjaguin, B (1934) Kolloid-Z, 69, 155-164.

Johnson, K. L. “A note on the adhesion of elastic solids”, British Journal of Applied Physics (1958), 9, 199-200.

K.L. Johnson, K. Kendall and A.D. Roberts, “Surface Energy and the Contact of Elastic Solids” Proc. R. Soc. A 324 (1971), 301–13

B.V. Derjaguin, V.M. Muller and Y.P. Toporov, J. Coll. Int. Sci., 53(2) (1975) 314–326

D. Tabor, J. Colloid Interface Sci. 58(1) (1977) 2–13

V.M. Muller, V. S. Yushenko and B.V. Derjaguin, J. Colloid Interface Sci. 77(1) (1980) 91–101

D. Maugis J. Colloid Interface Sci. 150(1) (1992) 243–269

J. A. Greenwood, K. L. Johnson, “An alternative to the Maugis model of adhesion between elastic spheres” J. Phys. D: Appl. Phys., 31(1998), 3279–3290

R. D. Mindlin and H. Deresiewicz, (1953) J. Appl. Mech. Trans. ASME, 20, 327–344.

C. Thornton, K. K. Yin, “Impact of elastic spheres with and without adhesion” Powder Technology, 65(1991),153-166

A.R. Savkoor and G. A. D. Briggs, “The Effect of Tangential Force on the Contact of Elastic Solids in Adhesion” Proc. Roy. Soc. A 356 (1977), 103

R. Di Felice (1994) Int. J. Multiphase Flow 20(I), 153-159

J. N. Israelachvili, Intermolecular and Surface Forces, (Academic Press, New York, 1985), 253.

G.R. Edwards and D.L. Olson: Annual Report, Center for Welding and Joining Research, Colorado School of Mines (1990), pp. 19, 26–27.

S.Y. Oh: Ph.D. Thesis, Department of Material Science and Engineering, MIT, 1987, p. 192.

B.J. Keene “Review of Data for the Surface Tension of Pure Metals”, International Materials Reviews 38-4, (1993), pp 157-192

J. J. Brennan, J. A. Pask, “Effect of Nature of Surfaces on wetting of Sapphire by Liquid Aliminum”, J. of The Americal Ceramic Society 51-10, (1968), pp 569-573

S. Bao, K. Tang, A. Kvithyld, T. Engh, and M. Tangstad: “Wetting of Pure aluminum on Graphite, SiC and Al2O3 in Aluminum Filtration”, Trans. Nonferrous Met. Soc. China 22 (2012), pp 1930-1938

Acknowledgments

The authors acknowledge financial support from the ExoMet Project (co-funded by the European Commission (contract FP7-NMP3-LA-2012-280421), by the European Space Agency and by the individual partner organizations).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 18, 2014.

Rights and permissions

About this article

Cite this article

Manoylov, A., Bojarevics, V. & Pericleous, K. Modeling the Break-up of Nano-particle Clusters in Aluminum- and Magnesium-Based Metal Matrix Nano-composites. Metall Mater Trans A 46, 2893–2907 (2015). https://doi.org/10.1007/s11661-015-2934-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2934-0