Abstract

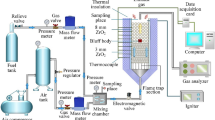

The utilization of coal mine methane (CMM) through porous medium combustion (PMC) contributes to energy saving and environmental protection. In this paper, a double-layer porous medium burner with the combination of heat exchangers was designed to recycle the exhausted heat for preheating the inlet gas. The effects of Raschig ring sizes on the temperature distributions and pollutant emissions were studied under different operating conditions. The results indicate that the preheating of inlet gas greatly influenced the temperature distribution and the optimum preheating effect was shown in the burner of spiral heat exchanger together with lower pollutant emissions. With the increasing of inlet velocity and equivalence ratio, the peak temperature was increased significantly. As the Raschig ring size increased, the flame temperature increased first and then decreased gradually. Meanwhile, the highest temperature and lowest average emissions of NOx and CO appeared in the burner of 10 mm Raschig rings. This study will provide the CMM utilization engineering with the theoretical foundation on PMC.

Similar content being viewed by others

References

Caldeira A.B., Susantez Ç., A simplified numerical approach to hydrogen and hydrocarbon combustion in single and double-layer porous burners. International Journal of Hydrogen Energy, 2020, 45: 35235–35245.

Bian Z., Inyang H.I., Daniels J.L., Otto F., Struthers S., Environmental issues from coal mining and their solutions. Mining Science and Technology (China), 2010, 20: 215–223.

Dai H., Zhao Q., Lin B., He S., Chen X., Zhang Y., Niu Y., Yin S., Premixed combustion of low-concentration coal mine methane with water vapor addition in a two-section porous media burner. Fuel, 2018, 213: 72–82.

Cheng Y., Wang L., Zhang X., Environmental impact of coal mine methane emissions and responding strategies in China. International Journal of Greenhouse Gas Control, 2011, 5: 157–166.

Banerjee A., Paul D., Developments and applications of porous medium combustion: A recent review. Energy, 2021, 221: 119868.

Habib R., Yadollahi B., Saeed A., Doranehgard M.H., Li L.K.B., Karimi N., Unsteady ultra-lean combustion of methane and biogas in a porous burner — An experimental study. Applied Thermal Engineering, 2021, 182: 116099.

Mujeebu M.A., Abdullah M.Z., Bakar M.Z.A., Mohamad A.A., Abdullah M.K., Applications of porous media combustion technology — A review. Applied Energy, 2009, 86: 1365–1375.

Chalia S., Bharti M.K., Thakur P., Thakur A., Sridhara S.N., An overview of ceramic materials and their composites in porous media burner applications. Ceramics International, 2021, 47: 10426–10441.

Mujeebu M.A., Abdullah M.Z., Bakar M.Z.A., Mohamad A.A., Abdullah M.K., A review of investigations on liquid fuel combustion in porous inert media. Progress in Energy and Combustion Science, 2009, 35: 216–230.

Mujeebu M.A., Abdullah M.Z., Mohamad A.A., Bakar M.Z.A., Trends in modeling of porous media combustion. Progress in Energy and Combustion Science, 2010, 36: 627–650.

Ellzey J.L., Belmont E.L., Smith C.H., Heat recirculating reactors: Fundamental research and applications. Progress in Energy and Combustion Science, 2019, 72: 32–58.

Qiu K., Hayden A.C.S., Increasing the efficiency of radiant burners by using polymer membranes. Applied Energy, 2009, 86: 349–354.

Xu K., Liu M., Zhao P., Stability of lean combustion in mini-scale porous media combustor with heat recuperation. Chemical Engineering and Processing: Process Intensification, 2011, 50: 608–613.

Song F., Wen Z., Dong Z., Wang E., Liu X., Ultra-low calorific gas combustion in a gradually-varied porous burner with annular heat recirculation. Energy, 2017, 119: 497–503.

Li J.W., Huang J.H., Chen X.J., Zhao D., Shi B.L., Wei Z.J., Wang N.F., Effects of heat recirculation on combustion characteristics of n-heptane in micro combustors. Applied Thermal Engineering, 2016, 109: 697–708.

Chaelek A., Grare U.M., Jugjai S., Self-aspirating/air-preheating porous medium gas burner. Applied Thermal Engineering, 2019, 153: 181–189.

Bakry A., Al-Salaymeh A., Al-Muhtaseb A.a.H., Abu-Jrai A., Trimis D., Adiabatic premixed combustion in a gaseous fuel porous inert media under high pressure and temperature: Novel flame stabilization technique. Fuel, 2011, 90: 647–658.

Wang G., Tang P., Li Y., Xu J., Durst F., Flame front stability of low calorific fuel gas combustion with preheated air in a porous burner. Energy, 2019, 170: 1279–1288.

Dai H., Lin B., Scale Effect of ceramic foam burner on the combustion characteristics of low-concentration coal mine methane. Energy & Fuels, 2014, 28: 6644–6654.

Barra A.J., Diepvens G., Ellzey J.L., Henneke M.R., Numerical study of the effects of material properties on flame stabilization in a porous burner. Combustion and Flame, 2003, 134: 369–379.

Wang Y., Zeng H., Shi Y., Cai N., Methane partial oxidation in a two-layer porous media burner with Al2O3 pellets of different diameters. Fuel, 2018, 217: 45–50.

Gao H., Qu Z., He Y., Tao W., Experimental study of combustion in a double-layer burner packed with alumina pellets of different diameters. Applied Energy, 2012, 100: 295–302.

Gao H., Qu Z., Feng X., Tao W., Combustion of methane/air mixtures in a two-layer porous burner: A comparison of alumina foams, beads, and honeycombs. Experimental Thermal and Fluid Science, 2014, 52: 215–220.

Dai H., Lin B., Ji K., Wang C., Li Q., Zheng Y., Wang K., Combustion characteristics of low-concentration coal mine methane in ceramic foam burner with embedded alumina pellets. Applied Thermal Engineering, 2015, 90: 489–498.

Zheng C., Cheng L., Li T., Luo Z., Cen K., Filtration combustion characteristics of low calorific gas in SiC foams. Fuel, 2010, 89: 2331–2337.

Xiong T.Y., Viskanta R., A basic study of a porous-matrix combustor-heater. Natural Gas, 1992.

Xiong T.Y., Khinkis M.J., Fish F.F., Experimental study of a high-efficiency, low emission porous matrix combustor—heater. Fuel, 1995, 74: 1641–1647.

Dai H., Lin B., Ji K., Hong Y., Two-dimensional experimental study of superadiabatic combustion in a packed bed burner. Energy & Fuels, 2015, 29: 5311–5321.

Contarin F., Saveliev A.V., Fridman A.A., Kennedy L.A., A reciprocal flow filtration combustor with embedded heat exchangers: numerical study. International Journal of Heat and Mass Transfer, 2003, 46: 949–961.

Jugjai S., Sawananon A., The surface combustor-heater with cyclic flow reversal combustion embedded with water tube bank. Fuel, 2004, 83: 2369–2379.

Liu J.F., Hsieh W.H., Experimental investigation of combustion in porous heating burners. Combustion and Flame, 2004, 138: 295–303.

Shi J., Xie M., Liu H., Liu H., Zhang X., Xu Y., Two-dimensional numerical study of combustion and heat transfer in porous media combustor-heater. Proceedings of the Combustion Institute, 2011, 33: 3309–3316.

Loukou A., Frenzel I., Klein J., Trimis D., Experimental study of hydrogen production and soot particulate matter emissions from methane rich-combustion in inert porous media. International Journal of Hydrogen Energy, 2012, 37: 16686–16696.

Loukou A., Mendes M.A.A., Frenzel I., Pereira J.M.C., Ray S., Pereira J.C.F., Trimis D., Experimental and numerical investigation of methane thermal partial oxidation in a small-scale porous media reformer. International Journal of Hydrogen Energy, 2017, 42: 652–663.

Wang Y., Zeng H., Shi Y., Cai N., Methane partial oxidation in a two-layer porous media burner with Al2O3 pellets of different diameters. Fuel, 2018, 217: 45–50.

Zeng H., Wang Y., Gong S., Shi Y., Cai N., Catalytically enhanced methane-rich combustion by porous media reactor. Fuel, 2019, 248: 65–75.

Dai H., Zhu H., Dai H., Song Z., Wang Z., He S., Wang X., Syngas production by methane-rich combustion in a divergent burner of porous media. International Journal of Hydrogen Energy, 2021. DOI: https://doi.org/10.1016/j.ijhydene.2021.04.160.

Tarokh A., Lavrentev A., Mansouri A., Numerical investigation of effect of porosity and fuel inlet velocity on diffusion filtration combustion. Journal of Thermal Science, 2021, 30: 1278–1288.

Song F., Wen Z., Fang Y., Wang E., Liu X., Combustion Wave Propagation of a Modular Porous Burner with Annular Heat Recirculation. Journal of Thermal Science, 2020, 29: 98–107.

Acknowledgments

The authors wish to acknowledge the support to this work by the National Key Research and Development Program of China (No. 2018YFC0808500), the National Natural Science Foundation of China (No. 51804237), the Natural Science Foundation of Hubei Province of China (No. 2018CFB207), and the Fundamental Research Funds for the Central Universities (WUT: 2019IVB035). Comments by all anonymous reviewers were highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, H., Zhu, H., Yang, P. et al. Combustion Characteristics of Coal Mine Methane in a Preheated-Burner Packed with Raschig Rings. J. Therm. Sci. 30, 1741–1750 (2021). https://doi.org/10.1007/s11630-021-1508-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-021-1508-2