Abstract

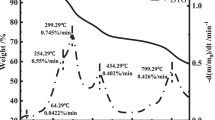

The addition of effective additives can effectively improve the pyrolysis performance of oil sludge (OS) and have a great potential to reduce pyrolysis costs. In the present study, co-pyrolysis performance of OS with different proportions of additives at a heating rate of 10°C/min was conducted in a thermal analyzer. Walnut shell, Fe2O3, K2CO3, PVC and the pyrolysis char produced from OS at the final pyrolysis temperature of 700°C were selected as the additives. TG results showed that the OS pyrolysis with and without additives can be divided into five reaction stages, which include volatilization of free water, the escape of light components, the cleavage of heavy components, carbon decomposition and inorganic minerals decomposition. The addition of additives decreased the maximum weight loss rate when the blending ratio was 5 wt% during OS pyrolysis. Kinetic analysis revealed that the overall activation energy of pyrolysis reaction was lower during pyrolysis of OS with the addition of walnut shells and pyrolysis char. The activation energy of three main reaction stages all decreased during co-pyrolysis of OS with K2CO3 and PVC.

Similar content being viewed by others

References

Cheng S., Wang Y., Gao N., Takahashi F., Li A., Yoshikawa K., Pyrolysis of oil sludge with oil sludge ash additive employing a stirred tank reactor. Journal of Analytical and Applied Pyrolysis, 2016, 120: 511–520.

Xue J., Huang C., Zhang Y., Liu Y., Gamal El-Din M., Bioreactors for oil sands process-affected water (OSPW) treatment: A critical review. Science of the Total Environment, 2018, 627: 916–933.

Gao N., Wang X., Quan C., Wu C., Study of oily sludge pyrolysis combined with fine particle removal using a ceramic membrane in a fixed-bed reactor. Chemical Engineering and Processing-Process Intensification, 2018, 128: 276–281.

Hu G., Li J., Zeng G., Recent development in the treatment of oily sludge from petroleum industry: a review. Journal of Hazardous Materious, 2013, 261: 470–490.

Gong Z., Wang Z., Wang Z., Fang P., Meng F., Study on pyrolysis characteristics of tank oil sludge and pyrolysis char combustion. Chemical Engineering Research and Design, 2018, 135: 30–36.

Karamalidis A.K., Voudrias E.A., Cement-based stabilization/solidification of oil refinery sludge: Leaching behavior of alkanes and PAHs. Journal of Hazardous Materials, 2007, 148(1–2): 122–135.

Gao Y., Ding R., Chen X., Gong Z., Zhang Y., Yang M., Ultrasonic washing for oily sludge treatment in pilot scale. Ultrasonics, 2018, 90: 1–4.

Parker H.D., Pitt G.D., Pollution control instrumentation for oil and effluents. Springer Netherlands, Dordrecht, 1987, pp. 309–316.

Wu X., Xie L., Li X., Dai X., Fei X., Jiang Y., Effect of wastewater treatment processes on the pyrolysis properties of the pyrolysis tars from sewage sludges. Journal of Thermal Science, 2011, 20(2): 167–172.

Lin B., Wang J., Huang Q., Chi Y., Effects of potassium hydroxide on the catalytic pyrolysis of oily sludge for high-quality oil product. Fuel, 2017, 200: 124–133.

Liu J., Jiang X., Zhou L., Wang H., Han X., Co-firing of oil sludge with coal-water slurry in an industrial internal circulating fluidized bed boiler. Journal of Hazardous Materials, 2009, 167(1–3): 817–823.

Gong Z., Liu C., Wang M., Wang Z., Li X., Experimental study on catalytic pyrolysis of oil sludge under mild temperature. Science of the Total Environment, 2020, 708: 135039.

Wang Z., Guo Q., Liu X., Cao C., Low temperature pyrolysis characteristics of oil sludge under various heating conditions. Energy & Fuels, 2007, 21(2): 957–962.

Chang C., Shie J., Lin J., Wu C., Lee D., Chang C., Major products obtained from the pyrolysis of oil sludge. Energy & Fuels, 2000, 14(6): 1176–1183.

Wang Z., Wang J., Xie L., Zhu H., Shu X., Influence of the addition of cotton stalk during co-pyrolysis with sewage sludge on the properties, surface characteristics, and ecological risks of biochars. Journal of Thermal Science, 2019, 28(4): 755–762.

Cheng S., Wang Y., Gao N., Takahashi F., Li A., Yoshikawa K., Pyrolysis of oil sludge with oil sludge ash additive employing a stirred tank reactor. Journal of Analytical and Applied Pyrolysis, 2016, 120: 511–520.

Shen Y., Chen X., Wang J., Ge X., Chen M., Oil sludge recycling by ash-catalyzed pyrolysis-reforming processes. Fuel, 2016, 182: 871–878.

Shie J., Lin J., Chang C., Lee D., Wu C., Pyrolysis of oil sludge with additives of sodium and potassium compounds. Resources, Conservation and Recycling, 2003, 39(1): 51–64.

Gong, Z., Wang, Z., Wang, Z., Du A., Fang P., Sun Z., Li X., Study on pyrolysis of oil sludge with microalgae residue additive. The Canadian Journal of Chemical Engineering, 2018, 96: 1919–1925.

Lin B., Huang Q., Chi Y., Co-pyrolysis of oily sludge and rice husk for improving pyrolysis oil quality. Fuel Processing Technology, 2018, 177: 275–282.

Trejo F., Centeno G., Ancheyta J., Precipitation, fractionation and characterization of asphaltenes from heavy and light crude oils. Fuel, 2004, 83(16): 2169–2175.

Cheng X., Zhang M., Wang Z., Xu G., Ma C., IR and kinetic study of sewage sludge combustion at different oxygen concentrations. Waste Management, 2018, 74: 279–287.

Liu J., Huang L., Sun G., Chen J., Zhuang S., Chang K., Xie W., Kuo J., He Y., Sun S., Buyukada M., Evrendilek F., (Co-)combustion of additives, water hyacinth and sewage sludge: Thermogravimetric, kinetic, gas and thermodynamic modeling analyses. Waste Management, 2018, 81: 211–219.

Xie W., Huang J., Liu J., Zhao Y., Chang K., Kuo J., He Y., Sun J., Zheng L., Xie W., Sun S., Buyukada M., Evrendilek F., Assessing thermal behaviors and kinetics of (co-)combustion of textile dyeing sludge and sugarcane bagasse. Applied Thermal Engineering, 2018, 131: 874–883.

Huang L., Liu J., He Y., Sun S., Chen J., Sun J., Chang K., Kuo J., Ning X., Thermodynamics and kinetics parameters of co-combustion between sewage sludge and water hyacinth in CO2/O2 atmosphere as biomass to solid biofuel. Bioresource Technology, 2016, 218: 631–642.

Brems A., Baeyens J., Beerlandt J., Dewil R., Thermogravimetric pyrolysis of waste polyethylene-terephthalate and polystyrene: A critical assessment of kinetics modelling. Resources Conservation & Recycling, 2011, 55(8): 772–781.

Korkut A., Thermogravimetric analysis of walnut shell as pyrolysis feedstock. Journal of Thermal Analysis and Calorimetry, 2011, 105(1): 145–150.

Vasudev V., Ku X., Lin J., Kinetic study and pyrolysis characteristics of algal and lignocellulosic biomasses. Bioresource Technology, 2019, 288: 121496.

Demirbas A., Effect of temperature on pyrolysis products from four nut shells. Journal of Analytical & Applied Pyrolysis, 2006, 76: 285–289.

Aygün A., Yenisoy-Karaka S., Duman I., Production of granular activated carbon from fruit stones and nutshells and evaluation of their physical, chemical and adsorption properties. Microporous & Mesoporous Materials, 2003, 66(2–3): 189–195.

Vamvuka D., Kakaras E., Kastanaki E., Grammelis P., Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite. Fuel, 2003, 82(15): 1949–1960.

Deng S., Wang X., Zhang J., Liu Z., Mikulčić H., Vujanović M., A kinetic study on the catalysis of KCl, K2SO4, and K2CO3 during oxy-biomass combustion. Journal of Environmental Management, 2018, 218: 50–58.

Yu J., Sun L., Ma C., Qiao Y., Yao H., Thermal degradation of PVC: A review. Waste Management, 2016, 48: 300–314.

Uzun B., Yaman E., Pyrolysis kinetics of walnut shell and waste polyolefins using thermogravimetric analysis. Journal of the Energy Institute, 2017, 90(6): 825–837.

Kar Y., Co-pyrolysis of walnut shell and tar sand in a fixed-bed reactor. Bioresource Technology, 2011, 102(20): 9800–9805.

Özsin G., Pütün A.E., TGA/MS/FT-IR study for kinetic evaluation and evolved gas analysis of a biomass/PVC co-pyrolysis process. Energy Conversion and Management, 2019, 182: 143–153.

Çepelioğullar Ö., Pütün A.E., A pyrolysis study for the thermal and kinetic characteristics of an agricultural waste with two different plastic wastes. Waste Management & Research, 2014, 32(10): 971–979.

Gong Z., Du A., Wang Z., Fang P., Li X., experimental study on pyrolysis characteristics of oil sludge with a tube furnace reactor. Energy & Fuels, 2017, 31(8): 8102–8108.

Tang F., Yu Z., Li Y., Chen L., Ma X., Catalytic co-pyrolysis behaviors, product characteristics and kinetics of rural solid waste and chlorella vulgaris. Bioresource Technology, 2020, 299: 122636.

Dai M.Q., Yu Z.S., Fang S.W., Ma X.Q., Behaviors, product characteristics and kinetics of catalytic co-pyrolysis spirulina and oil shale. Energy Conversion and Management, 2019, 192: 1–10.

Acknowledgement

The research was supported by Natural Science Foundation of Shandong Province (ZR2020QE199), State Key Laboratory of Pollution Control and Resource Utilization research (No. PCRRF19023) and Key Research and Development Program of Liaoning Province (No. 2020JH2/10300099).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, Z., Zhang, H., Liu, C. et al. Co-Pyrolysis Characteristics and Kinetic Analysis of Oil Sludge with Different Additives. J. Therm. Sci. 30, 1452–1467 (2021). https://doi.org/10.1007/s11630-021-1421-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-021-1421-8