Abstract

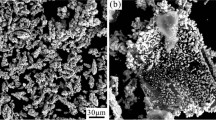

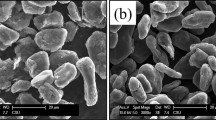

Copper-graphite composites were prepared by spark plasma sintering (SPS) using copper-coated graphite powder. Hydrophobic surfaces were successfully constructed by chemical etching and surface treatment. The density, metallographic structure, microstructure, Shore hardness, resistivity, water contact angle, and friction/wear properties of the composites were investigated using the Archimedes drainage method, a metallographic microscope, a scanning electron microscope, a hardness tester, a resistometer, a surface science tester, and a friction tester. The results showed that the relative density and Shore hardness of the copper—graphite composites increased slightly from 90.04% and 56 HSD to 92.66% and 59 HSD, respectively, when the sintering temperature increased from 700 to 900 °C. The copper and graphite phases in the copper-graphite composites were uniformly distributed with a continuous and network-like structure at various sintering temperatures. The interface between the copper and graphite was in good condition, without any obvious cracks or voids. The optimum process for hydrophobic surface construction included etching with a 1 mol/L K2Cr2O7-H2SO4 solution for 1 min, and soaking in a 0.09 mol/L cetylbenzene sulfonic acid alcohol solution for 1 h. The contact angle of the copper—graphite composite reached 130°. Hydrophobic treatment was beneficial for reducing the friction coefficient (from 0.18–0.19 to 0.13–0.15) and the wear rate (from 4.1–6.2×10−3 to 1.1–2.1×10−3 mm3/(N·m)), demonstrating obvious antifriction and wear-resisting properties. The resistivities of the hydrophobic-treated samples increased slightly, from (4–8)×10−7 Ω·m to (5–15)×10−7 Ω·m, meeting the resistivity requirements of copper-graphite composite pantograph sliders and current receiver sliders in actual working conditions.

Similar content being viewed by others

References

Cao H. Effect of Emulsified Asphalt on the Microstructure and Properties of Copper Graphite Pantograph Slide[D]. Kunming: Kunming University of Science and Technology, 2018

Cheng J J, Gan X P, Chen S Q, et al. Properties and Microstructure of Copper/Nickel-Iron-Coated Graphite Composites Prepared by Electro-less Plating and Spark Plasma Sintering[J]. Powder Technology, 2019. 343: 705–713

Daoush W M, Lim B K, Mo C B, et al. Electrical and Mechanical Properties of Carbon Nanotube Reinforced Copper Nanocomposites Fabricated by Electroless Deposition Process[J]. Materials Science and Engineering A, 2009, 513: 247–253

Cui X, Gao W. Research Status and Development Prospect of Biomimetic Superhydrophobic Materials[J]. Knitting Industry, 2018, 1: 63–67

Bhushan B, Yong C J. Natural and Biomimetic Artificial Surfaces for Superhydrophobicity, Self-cleaning, Low Adhesion, and Drag Reduction[J]. Progress in Materials Science, 2011, 56(1): 1–108

Yan Y Y, Gao N, Barthlott W. Mimicking Natural Superhydrophobic Surfaces and Grasping the Wetting Process: A Review on Recent Progress in Preparing Superhydrophobic Surfaces[J]. Advances in Colloid & Interface Science, 2011, 169(2): 80–105

Jamali M, Vahedi Tafreshi H, Pourdeyhimi B. Penetration of Liquid Droplets into Hydrophobic Fibrous Materials under Enhanced Gravity[J]. Journal of Applied Physics, 2019, 125(14): 145304–145316

Li K, Zeng X, Li H, et al. A Study on the Fabrication of Superhydrophobic Iron Surfaces by Chemical Etching and Galvanic Replacement Methods and Their Anti-icing Properties[J]. Applied Surface Science, 2015, 346: 458–463

Chen T, Ge S, Liu H, et al. Fabrication of Low Adhesive Superhydro-phobic Surfaces Usingnano Cu/Al2O3Ni-Cr Composited Electro-brush Plating[J]. Applied Surface Science, 2015, 356: 81–90

Li Y, Wan Y, Dong Z, et al. Excellent Friction-reducing Performance of Superhydrophobic Steel Surface in Dry Sliding[J]. R.S.C Advances, 2014, 4(39): 20548–20553

Li P, Chen X, Yang G, et al. Fabrication and Characterization of Stable Superhydrophobic Surface with Good Friction-reducing Performance on Al Foil[J]. Applied Surface Science, 2014, 300: 184–190

Shao G S, Liu P, Zhang K, et al. Mechanical Properties of Graphene Nanoplates Reinforced Copper Matrix Composites Prepared by Electrostatic Self-assembly and Spark Plasma Sintering[J]. Materials Science and Engineering A, 2019, 739: 329–334

Deng H, Yi J H, Xia C, et al. Improving the Mechanical Properties of Carbon Nanotube-reinforced Pure Copper Matrix Composites by Spark Plasma Sintering and Hot Rolling[J]. Materials Letters, 2018, 210:177–181

Zhang H. Construction of Super-hydrophobic Surface of 45# Steel and Its Anti-corrosion and Tribological Properties[D]. Zhenjiang: Jiangsu University, 2016

Wang H J, Yu J, Wu Y Z, et al. A Facile Two-step Approach to Prepare Superhydrophobic Surfaces on Copper Substrates[J]. Journal of Materials Chemistry A, 2014, 2(14): 5010–5017

Nguyen T B, Park S, Jung Y, et al. Effects of Hydrophobicity and Lubricant Characteristics on Anti-icing Performance of Slippery Lubricant-infused Porous Surfaces[J]. Journal of Industrial and Engineering Chemistry, 2019, 69: 99–105

Huang J Y, Wei S B, Zhang L X, et al. Fabricating the Superhydrophobic Nickel and Improving Its Antifriction Performance by the Laser Surface Texturing[J]. Materials, 2019, 12: 1155, doi:https://doi.org/10.3390/ma12071155

Pal V K, Balani K, Choudhury S K, et al. Hydrophobicity and Tribology of Large-area Textured Copper with Nanogrown Copper Oxide[J]. Surface Innovations, 2016, 4(4): 205–213

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Open Subject of The State Key Laboratory of Heavy Duty AC Drive Electric Locomotive Systems Integration (No. 172195100710)

Rights and permissions

About this article

Cite this article

Zou, J., Wei, H. & Xiao, C. Effect of Sintering Temperature and Hydrophobic Treatment on the Microstructure and Properties of Copper-Graphite Composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 305–313 (2022). https://doi.org/10.1007/s11595-022-2532-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2532-0