Abstract

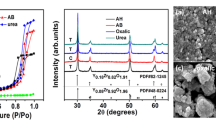

We investigated the impure phase problem and summarized its two formation mechanisms of YAG powders synthesized via the co-precipitation method. The ions loss problem caused by high concentration reaction solution in the titration process was emphatically studied, and the corresponding thermodynamic explanation was carried out. In addition, influence of powder crystallinity and its new qualitative and quantitative standards were studied. One reason of impure phase is the local nonuniform mixture of Y and Al elements in precursor, which easily causes intermediate phases during calcination and difficulty of high pure powders at low temperatures. The other reason is the precipitation dissolution during titration and then the Y3+/Al3+ loss, caused by high concentration of reaction solution. The powder crystallinity can be promoted by increasing calcination temperature or holding time of precursor. Besides the routine XRD method, the TEM-EDX method should be also introduced to directly determine the quality of crystallinity.

Similar content being viewed by others

References

Ikesue A, Aung YL. Ceramics Laser Materials[J]. Nat. Photon., 2008, 2: 721–727

Kochawattana S, Stevenson A, Lee SH, et al. Sintering and Grain Growth in SiO2 Doped Nd:YAG[J]. J. Am. Ceram. Soc., 2008, 28: 1 527–1 534

Zhao Y, Liu Q, Ge L, et al. Tape Casting Fabrication and Properties of Planar Waveguide YAG/Yb:YAG/YAG Transparent Ceramics[J]. Opt. Mater., 2017, 69: 169–174

Chrétien L, Bonnet L, Boulesteix R, et al. Influence of Hot Isostatic Pressing on Sintering Trajectory and Optical Properties of Transparent Nd:YAG Ceramics[J]. J. Eur. Ceram. Soc., 2016, 36: 2 035–2 042

Bagayev SN, Osipov VV, Vatnik SM, et al. Ho:YAG Transparent Ceramics Based on Nanopowders Produced by Laser Ablation Method: Fabrication, Optical Properties, and Laser Performance[J]. Opt. Mater., 2015, 50: 47–51

Hostaša J, Esposito L, Piancastelli A. Influence of Yb and Si Content on the Sintering and Phase Changes of Yb:YAG Laser Ceramics[J]. J. Eur. Ceram. Soc., 2012, 32: 2 949–2 956

Ma C, Zhu J, Nan X, et al. Demonstration and CW Laser Performances of Composite YAG/Nd:LuAG/YAG Transparent Laser Ceramic[J]. J. Alloys. Compd., 2017, 727: 912–918

Denker B, Galagan B, Osiko V, et al. Yb3+, Er3+: YAG at High Temperatures: Energy Transfer and Spectroscopic Properties[J]. Opt. Commun., 2007, 271: 142–147

Xu J, Shi Y, Xie J, et al. Fabrication, Microstructure, and Luminescent Properties of Ce3+-Doped Lu3Al5O12 (Ce:LuAG) Transparent Ceramics by Low-Temperature Vacuum Sintering[J]. J. Am. Ceram. Soc., 2013, 96: 1 930–1 936

Zhou T, Zhang L, Zhang J, et al. Improved Conversion Efficiency of Cr4+ Ions in Cr:YAG Transparent Ceramics by Optimization the Particle Sizes of Sintering Aids[J]. Opt. Mater., 2015, 50: 11–14

Stevenson AJ, Li X, Martinez MA, et al. Effect of SiO2 on Densification and Microstructure Development in Nd:YAG Transparent Ceramics[J]. J. Am. Ceram. Soc., 2011, 94: 1 380–1 387

Suárez M, Fernández A, Menéndez JL, et al. Hot Isostatic Pressing of Optically Active Nd:YAG Powders Doped by a Colloidal Processing Route[J]. J. Eur. Ceram. Soc., 2010, 30: 1 489–1 494

Frage N, Kalabukhov S, Sverdlov N, et al. Effect of the Spark Plasma Sintering (SPS) Parameters and LiF Doping on the Mechanical Properties and the Transparency of Polycrystalline Nd-YAG[J]. Ceram. Int., 2012, 38: 5 513–5 519

Yavetskiy RP, Vovk EA, Doroshenko AG, et al. Y3Al5O12 Translucent Nanostructured Ceramics-obtaining and Optical Properties[J]. Ceram. Int., 2011, 37: 2 477–2 484

Spina G, Bonnefont G, Palmero P, et al. Transparent YAG Obtained by Spark Plasma Sintering of Co-precipitated Powder. Influence of Dispersion Route and Sintering Parameters on Optical and Microstructural Characteristics[J]. J. Eur. Ceram. Soc., 2012, 32: 2 957–2 964

Huang H, Gong H, Tang D, et al. Synthesis and Characterization of Yttrium Aluminum Garnet by High-energy Ball Milling[J]. Opt. Mater., 2009, 31: 716–719

Appiagyei KA, Messing GL, Dumm JQ. Aqueous Slip Casting of Transparent Yttrium Aluminum Garnet (YAG) Ceramics[J]. Ceram. Int., 2008, 34: 1 309–1 313

Yang H, Qin XP, Zhang J, et al. Fabrication of Nd:YAG Transparent Ceramics with both TEOS and MgO Additives[J]. J. Alloys. Compd., 2011, 509: 5 274–5 279

Ikesue A, Yoshida K, Yamamoto T, et al. Optical Scattering Centers in Polycrystalline Nd:YAG Laser[J]. J. Am. Ceram. Soc., 1997, 80: 1 517–1 522

Liu W, Jiang B, Zhang W, et al. Influence of Heating Rate on Optical Properties of Nd:YAG Laser Ceramics[J]. Ceram. Int., 2010, 36: 2 197–2 201

Katz A, Barraud E, Lemonnier S, et al. Role of LiF Additive on Spark Plasma Sintered Transparent YAG Ceramics[J]. Ceram. Int., 2017, 43: 15 626–15 634

Yao Q, Zhang L, Jiang Z, et al. Isobam Assisted Slurry Optimization and Gelcasting of Transparent YAG Ceramics[J]. Ceram. Int., 2018, 44: 1 699–1 704

Kraxner J, Chovanec J, Haladejová K, et al. Hollow Polycrystalline YAG Microspheres by Flame Synthesis[J]. Mater. Lett., 2017, 204: 181–183

Lu J, Prabhu M, Song J, et al. Optical Properties and Highly Efficient Laser Oscillation of Nd:YAG Ceramics[J]. Appl. Phys. B, 2000, 71: 469–473

Yagi H, Yanagitani T, Takaichi K, et al. Characterizations and Laser Performances of Highly Transparent Nd3+:Y3Al5O12 Laser Ceramics[J]. Opt. Mater., 2007, 29: 1 258–1 262

Li J, Wu YS, Pan YB, et al. Fabrication, Microstructure and Properties of Highly Transparent Nd:YAG Laser Ceramics[J]. Opt. Mater., 2008, 31: 6–17

Guo W, Cao Y, Huang Q, et al. Fabrication and Laser Behaviors of Nd:YAG Ceramic Microchips[J]. J. Eur. Ceram. Soc., 2011, 31: 2 241–2 246

Wei N, Lu T, Li F, et al. Transparent Ce:Y3Al5O12 Ceramic Phosphors for White Light-emitting Diodes[J]. Appl. Phys. Lett., 2012, 101: 061902

Singh R, Khardekar RK, Kumar A, et al. Preparation and Characterization of Nanocrystalline Nd-YAG Powder[J]. Mater. Lett., 2007, 61: 921–924

Rabinovitch Y, Bogicevic C, Karolak F, et al. Freeze-dried Nanometric Neodymium-doped YAG Powders for Transparent Ceramics[J]. J. Mater. Process. Technol., 2008, 199: 314–320

Li X, Li Q, Wang J, et al. Synthesis of Nd3+ Doped Nano-crystalline Yttrium Aluminum Garnet (YAG) Powders Leading to Transparent Ceramic[J]. Opt. Mater., 2007, 29: 528–531

Wen L, Sun X, Xiu ZM, et al. Synthesis of Nanocrystalline Yttria Powder and Fabrication of Transparent YAG Ceramics[J]. J. Eur. Ceram. Soc., 2004, 24: 2 681–2 688

Lu Q, Dong W, Wang H, et al. A Novel Way to Synthesize Yttrium Aluminum Garnet from Metal-inorganic Precursors[J]. J. Am. Ceram. Soc., 2002, 85: 490–492

Wildfire C, Sabolsky EM, Spencer MJ, et al. Solid-state Synthesis of YAG Powders Through Microwave Coupling of Oxide/Carbon Particulate Mixtures[J]. Ceram. Int., 2017, 43: 11 455–11 462

Su X, Zhou J, Bai G, et al. Low Temperature Synthesis and Characterization of YAG Nanopowders by Polyacrylamide Gel Method[J]. Ceram. Int., 2016, 42: 17 497–17 502

Su J, Zhang QL, Gu CJ, et al. Preparation and Characterization of Y3Al5O12 (YAG) Nano-powder by Co-precipitation Method[J]. Mater. Res. Bull., 2005, 40: 1 279–1 285

Li JG, Ikegami T, Lee JH, et al. Co-precipitation Synthesis and Sintering of Yttrium Aluminum Garnet (YAG) Powders: the Effect of Precipitant[J]. J. Eur. Ceram. Soc., 2000, 20: 2 395–2 405

Lu Z, Lu T, Wei N, et al. Novel Phenomenon on Valence Unvariation of Doping Ion in Yb:YAG Transparent Ceramics using MgO Additives[J]. J. Wuhan. Univ. Technol-Mater. Sci. Ed., 2013, 28: 320–324

Li J, Chen F, Liu W, et al. Co-precipitation Synthesis Route to Yttrium Aluminum Garnet (YAG) Transparent Ceramics[J]. J. Eur. Ceram. Soc., 2012, 32: 2 971–2 979

Wang H, Gao L, Niihara K. Synthesis of Nanoscaled Yttrium Aluminum Garnet Powder by the Co-precipitation Method[J]. Mater. Sci. Eng. A, 2000, 288: 1–4

Li J, Sun X, Liu S, et al. A Homogenuous Co-precipitation Method to Synthesize Highly Sinterability YAG Powders for Transparent Ceramics[J]. Ceram. Int., 2015, 41: 3 283–3 287

Qiu Q, Huang M, Zheng W, et al. Impact of Molar Ratio of Total Metal Ions to Precipitant on YAG:Ce Nanophosphors Synthesized by Reverse Titration Coprecipitation[J]. Ceram. Int., 2017, 43: 8 730–8 734

Marlot C, Barraud E, Gallet SL, et al. Synthesis of YAG Nanopowder by the Co-precipitation Method: Influence of pH and Study of the Reaction Mechanisms[J]. J. Solid. State. Chem., 2012, 191: 114–120

Rahmani M, Mirzaee O, Tajally M, et al. The Effects of pH and Excess Al3+ Content on the Microstructure and Phase Evolution of YAG Polycrystals[J]. Ceram. Int., 2017, 43: 12 563–12 571

Ma B, Lu T, Xiao S, et al. Preparation of YAG Powder by Co-precipitation Method in a Narrow pH-change Environment[J]. J. Wuhan. Univ. Technol-Mater. Sci. Ed., 2010, 25: 379–383

Guo W, Lu T, Tong S. Effect of Phase of YAG Powder Synthesized by Co-precipitation on Transparent Ceramic Sintering[J]. Key Eng. Mater., 2007, 336–338: 2 054–2 057

Cao XZ, Song TY, Wang XQ. Inorganic Chemistry[M]. 3rd ed. Bei Jing: Higher Education Press, 1994

Ma B, Wang B, Zhang W, et al. Promotion of Powder Crystallinity and Its Influence on the Properties of Nd:YAG Transparent Ceramics[J]. Opt. Mater., 2017, 64: 383–390

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Science Fund of Educational Department of Henan Province of China (No. 19A430002)

Rights and permissions

About this article

Cite this article

Ma, B., Pu, C., He, J. et al. Formation Mechanism of Impure Phases and Crystallinity Investigation of YAG Powders Synthesized via the Co-precipitation Method. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 517–525 (2021). https://doi.org/10.1007/s11595-021-2439-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2439-1