Abstract

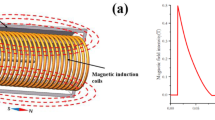

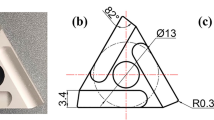

In order to study the effect of electromagnetic compound treatment on the mechanical property, cutting performance and microstructure of cemented carbide, the samples were treated by a self-made electromagnetic compound treatment device with different magnetic field strength (H=1, 1.25 and 1.5 T). The electromagnetic compound treatment method was proposed to couple pulsed magnetic field and pulsed current. The results show that after the pulsed magnetic field treatment, the values of the transverse rupture strength of the samples were respectively reduced by 21%, 20.6% and 20.1%; the cutting performance was decreased by about 4.5%, which means the tool life was decreased. After the electromagnetic compound treatment, the values of the transverse rupture strength of the rectangular samples were respectively increased by 8%, 8.6% and 9.5%, and the tool life was increased by 4.2%, 7% and 10.3%. After the electromagnetic compound treatment, the pulse current provided the driving force for dislocation motion. A strong pulse current driving force is more likely to make the dislocation multiply and slip. A high density dislocation cell is formed within the material, so the mechanical properties were significantly increased.

Similar content being viewed by others

References

D Paulmier, Helal Z. Steel Surface Modifications in Magnetised Sliding Contact[J]. Surface and Coatings Technology, 1995, 76–77 (2): 583–588

Paul C. Look at Magnetic Treatment of Tools and Wear Surfaces[J]. Tooling and Production, 1990, 55 (12): 100–103

R F Hochman, N Tselesin, V Drits. Magnetic Fields: Fertile Ground for Metals Processing[J]. Advanced Materials and Processes, 1998, 8): 36–41

Omar B, Barney K, Barry G. Effect of Pulsed Magnetic Treatment on Drill Wear[J]. Journal of Materials Processing Technology, 2003, 134 (2): 190–196

M S C Bose. Effect of Saturated Magnetic-field on Fatigue Life of Carbon-steel[J]. Physica Status Solidi A, 1984, 86): 649–654

Yusef F, Tom H, Conrad. Effects of a Pulsed Magnetic Treatment on The Fatigue of Low Carbon Steel [J]. Scripta Materialia, 1998, 38 (9): 1 355–1 358

S N Prasad, P N Singh, Vakil S. Influence of Pulsating Magnetic Field on Softening Behaviour of Cold Rolled AISI 4340 Steel at Room Temperature[ J]. Singh, Scripta Materialia, 1996, 34 (12): 1 857–1 860

Lv B T, Qiao S R, Sun X Y. Exploration on Repairing Fatigue Damage of Steel Specimens with Magnentic Treatment[J]. Scripta Materialia, 1999, 40 (7): 767–771

Barney E K. Residual Stress Reduction by Pulsed MagneticTreatment[ J]. Journal of Materials Processing Technology, 2003, 141(3): 385–394

Tang F, Lu A L, Fang H Z, et al. Effect of Magnetic Treatment on Magnetostrictive Behaviour of HT70 Steel[J]. Materials Science and Engineering A, 1998, 248): 98–100

Lu A L, Tang F, Luo X J, et al. Research on Residual-stress Reduction by Strong Pulsed Magnetic Treatment[J]. Journal of Materials Processing Technology, 1998, 74: 259–262

Tang F, Lu A L, Mei J F, et al. Research on Residual Stress Reduction by a Low Frequency Alternating Magnetic Field[J]. Journal of Materials Processing Technology, 1998, 74): 255–258

Tang F. Research on Residual Stress Reduction in Steel by Pulsed Magnetic Treatment[D]. Beijing: Tsinghua University, 1999

Zhang L, Zhou W, Hu P H, et al. Microstructural Characteristics and Mechanical Properties of Mg-Zn-Y Alloy Containing Icosahedral Quasicrystals Phase Treated by Pulsed Magnetic Field[J]. Journal of Alloys and Compounds, 2016, 688): 868–874

Fu J W, Yang Y S. Microstructure and Mechanical Properties of Mg–Al-Zn Alloy under a Low-voltage Pulsed Magnetic Field[J]. Materials Letters, 2012, 67): 252–255

Zhang L, Li W, Yao J. P, et al. Effects of Pulsed Magnetic Field on Microstructures and Morphology of the Primary Phase in Semisolid A356 Al Slurry[J]. Materials Letters, 2012, 66): 190–192

Troitskii O A, Spitsyn V I, Sokolov N V, et al. Application of High-density Current in Plastic Working of Metals[J]. Physica Status Solidi (A) Appiled Research, 1979, 52(1): 85–93

Kiryanchev N E, Troitskii O A, Klevtsur S A. Electroplastic Deformation of Metals[J]. ProblemyProchnosti, 1983, 5(5): 167–170

Mkaddem A, Benabou A. Analytical Modeling to Predict the Cutting Behavior of Ferromagnetic Steels: A Coupled Magnetic-mechanical Approach[J]. International Journal of Solids & Structures, 2013, 50(13): 2078–2086

Chin K J, Zaidi H, Nguyen M T, et al. Tribological Behavior and Surface Analysis of Magnetized Sliding Contact XC 48 Steel[J]. Wear, 2001, 250): 470–476

Chin K J, Zaidi H, Mathia T. Oxide Film Formation in Magnetized Sliding Steel/steel Contact -Analysis of the Contact Stress Field and Film Failure Mode[J]. Wear, 2005, 259): 477–481

Sehijpal S, Shan H S, Pradeep K. Parametric Optimization of Magnetic-field-assisted Abrasive Flow Machining by the Taguchi Method[J]. Journal of Materials Processing Technology, 2002, 128): 155–158

Zaidi H, Pan L, Paulmier D, et al. Influence of a Magnetic-field on the Wear and Friction Behavior of a Nickel Xc-48 Steel[J]. Wear, 1995, 181): 799–804

Jiang J, Tian Y, Meng Y G. Role of External Magnetic Field During Friction of Ferromagnetic Materials[J]. Wear, 2011, 271): 2991–2 997

Lu R C, Yuan S Q, Cao Y L, et al. Research Status on Applying Electric Pulsing Treatment in Metallic Materials[J]. Material & Heat Treatment, 2009 (6): 52–55

Yang S Z, Li N, Wen Y H. Effect of Electropulsing Treatment on the Shape Memory Effect of Fel4Mn6Si8Cr5Ni Solid Solution Alloy[J]. Journal of Sichuan University, 2010, 42(2): 232–236

Yan J, Cen Q H, Jiang Y H, et al. As-cast Microstructure of High-boron Middle-carbon Alloy Tool Steel[J]. Journal of Materials Engineering, 2013, 3(6): 55–59

Zhan L C, Chi H X, Ma D S, et al. The As-cast Microstructure of ESRCDS M2 High Speed Steel[J]. Journal of Materials Engineering, 2013, 24(7): 29–34

Li Q, Cen Q, Jiang Y, et al. Effects of Electric Pulse on Solidification Structure of High-boron Middle-carbon Alloy Steel[J]. Special Casting and Nonferrous Alloys, 2012, 32(12): 1095–1098

Conrad H, Karam N, Mannan S. Effect of Electric Current Pulse on the Recrystallization of Copper[J]. Script Metall, 1983, 17): 411–415

Tian B. Research of Thermal Fatigue Recover of Hot Work Die Steel Treated by Current Pulse[D]. Changchun: Jilin University, 2007

Zhang Y J. Effect of Electropulsing and Annealing Treatment on Thermal Fatigue Property of HHD Steel Weld[D]. Changchun: Jilin University, 2007

Sprecher A F, Mannan S L, Conrad H. On the Temperature Rise Associated with the Electroplastic Effect in Titanium[J]. Scripta Metallurgica, 1983, 17 (6): 769–773

Zhang J. The Application of “Electroplastic Effect” in Wire-Drawing Process and Analysis on Its Mechanism[D]. Beijing: Tsinghua University, 2000

Li Q C, Li L J. Effects of Pulsed Current and Pulsed Magnetic Field Complex Pretreatment on Martensite Transformation of Cr5 Steel during Continuous Cooling[J]. Journal of Iron & Steel Research International, 2015, 22(12): 1 131–1 137

Li D. The Mechanism and Experimental Study of Electroplastic Effect on Metal Flow Stress[D]. Yanshan: Yanshan University, 2006

Antolovich S D, Conrad H. The Effects of Electric Currents and Fields on Deformation in Metals, Ceramics, and Ionic Materials: An Interpretive Survey[J]. Materials and Manufacturing Processes, 2004, 19(4): 587–591

H C, A F S. Dislocations in Solids[M]. Amsterdam: Elsevier Science Publications, 1989

CAO F R. Electron Wind Stress Model and Calculation Examples under Pulse Current[J]. Advances in Condensed Matter Physics, 2017, 6(1): 1–5

Li J, He P. Study on Microstructure and Properties of WC-Co Cemented Carbides[J]. Rare Metal Materials and Engineering, 1995, 24(3): 53–56

Gerhard G, J B, B G. Advanced and New Grades of WC and Binder Powder-Their Properties and Application[J]. Refractory Metals & Hard Materials, 2000, 18(2): 87–102

Li J, Guo X, Yao J, et al. Effect of Magnetic Quenching on Performance and Structure of Cemented Carbides[J]. Journal of Central South University (Science and Technology), 2012, 43(7): 2513–2 516

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (Nos.51575369 & 51675357)

Rights and permissions

About this article

Cite this article

Wei, L., Yang, Y., Yang, G. et al. Effect of Electromagnetic Compound Treatment on Microstructure and Performance of Cemented Carbide. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 1119–1126 (2019). https://doi.org/10.1007/s11595-019-2168-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2168-x