Abstract

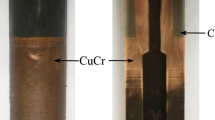

The arc erosion under medium direct currents in the argon flow was tested on tungsten-copper (W-Cu) contacts which were processed by hot extrusion and heat treatment. The scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were used to study the microstructure of the W-Cu powders and compacts. The contact resistance, arcing energy, and arcing time were continuously measured by JF04C contact materials test system. Changes in tungsten-copper contact surface were observed by SEM. The test results showed that the arcing time and arcing energy all increase with current and voltage, but the changes of average contact resistance are more complicated. For a short arcing time, the average contact resistance decreases with increasing current due to the vaporization of Cu. However, for a longer arcing time, it slightly increases due to the formation of high resistant films, compound copper tungsten. The formation of compound copper tungsten was confirmed by the increased Rc kept in the range from 1.1 to 1.6 mΩ. The compound copper tungsten is first exposed with a tungsten and copper-rich surface, and then totally exposed due to evaporation of copper from the surface. At last a stabilized surface is created and the crystals decrease from 8 μm to 2 μm caused by the arc erosion.

Similar content being viewed by others

References

Slade PG. Electrical Contacts: Principles and Applications[M]. New York: CRC press, 2014: 879–880

Liu S, Yu K, Shen Q, et al. Fabrication of WCu Composite Powders by Direct Electroless Plating Using a Dripping Method[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2013, 28: 829–33

Luo S, Yi J, Guo Y, et al. Consolidation and Microstructures of Microwave Sintered W-25Cu Alloys with Fe Addition[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2010, 25: 437–43

Tao J, Shi X. Properties, Phases and Microstructure of Microwave Sintered W-20Cu Composites from Spray Pyrolysis-continuous Reduction Processed Powders[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2012, 27: 38–44

Zhang Q, Shi X, Yang H, et al. Microstructure and Properties of W-15Cu Alloys Prepared by Mechanical Alloying and Spark Plasma Sintering Process[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2008, 23: 399–402

Wang J, Tie S, Kang Y, et al. Contact Resistance Characteristics of Ag-SnO2 Contact Materials with High SnO2 Content[J]. Journal of Alloys and Compounds, 2015, 644: 438–443

Myshkin NK. Tribological Problems in Electrical Contacts[J]. Tribology International, 1991, 24(1): 45–49

Slade PG. Effect of the Electric Arc and the Ambient Air on the Contact Resistance of Ag, W, and W-Ag Contacts [J]. Journal of Applied Physics, 1976, 47(8): 3438–3443

Hashempour M, Razavizadeh H, Rezaie H. Investigation on Wear Mechanism of Thermochemically Fabricated W-Cu Composites[J]. Wear, 2010, 269: 405–415

Slade PG, Li WP, Mayo S, et al. Vacuum Interrupter, High Reliability Component of Distribution Switches, Circuit Breakers and Contactors[J]. J Zhejiang Univ-SCI A, 2007, 8: 335–342.

Ma DQ, Xie JP, Li JW, et al. Synthesis and Hydrogen Reduction of Nano-sized Copper Tungstate Powders Produced by a Hydrothermal Method[J]. International Journal of Refractory Metals & Hard Materials, 2014, 46: 152–158

Dorfman LP, Houck DL, Scheithauer MJ. Consolidation of Tungsten-coated Copper Composite powder[J]. Journal of Materials Research, 2002, 17(8): 2075–2084

Xie X, Lin Q, Liu D, et al. Research on the Densification of W-30wt%-Cu Composite Powder by Hot Extrusion with Steel Cup[J]. Materials Science and Engineering: A, 2013, 578: 187–190

Chen ZK, Sawa K. Effect of Arc Behavior on Material Transfer: A Review[C]. In: Joint with the 18th International Conference on Electrical Contacts, IEEE, 1996: 238–251

Slade PG. Advances in Material Development for High Power, Vacuum Interrupter Contacts[J]. IEEE Transactions on Components, Packing, and Manufacturing Technology, 1994, 17: 96–106

Boyle WS, Geriner LH. Arcing at Electricalcontacts on Closure. Part VI. The anode Mechanism of Extremely Short Arcs[J]. Journal of Applied Physics, 1955, 26: 571–574

Chen W, Kang Z, Ding B. Preparation and Arc Breakdown Behavior of Nanocrystalline W-Cu Electrical Contact Materials[J]. Journal of Materials Science & Technology, 2005, 21: 875–878

Ding T, Chen GX, Li YM, et al. Arc Erosive Characteristics of a Carbon Strip Sliding Against a Copper Contact Wire in a High-speed Electrified Railway[J]. Tribology International, 2014, 79: 8–15

Leung C, Bevington R, Wingert P, et al. Effects of Processing Methods on the Contact Performance Parameters for Silver-tungsten Composite Materials[J]. IEEE Trans CHMT, 1982, 5(1): 23–31

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, D., Xie, J., Li, J. et al. Contact resistance and arc erosion of tungsten-copper contacts in direct currents. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 816–822 (2017). https://doi.org/10.1007/s11595-017-1674-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1674-y