Abstract

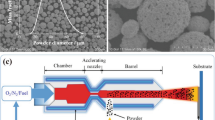

The objective of the present work was to determine the influence of the neutral salt spray corrosion on the wear resistance of HVOF sprayed NiCr-Cr3C2 coating with intermediate layer. Ni-Zn-Al2O3 coatings as interlayers were prepared by low pressure cold spray (LPCS) between NiCr-Cr3C2 cermet coatings to form a sandwich structure to enhance the corrosion resistance properties. The tribological properties were examined using the UMT-3 fricition and wear tester by line-contact reciprocating sliding under dry and salt spray one week corrosion. The morphology, element distribution, and phase compositions of the coating and worn sufaces were analyzed by using scanning electron microscopy, energy dispersive spectrometry, and X-ray diffraction respectively. The corrosion behavior of the coating was studied by the open-circuit potential, the electrochemical impedance spectroscopy, potentiodynamic polarization, and salt spray corrosion methods. It is found that the sandwich structured coating has better corrosion resistance than the single layer coating. The results show that under dry wear conditions, the wear mechanism is abrasive and adhesive wear, whereas under salt spray corrosion conditions it becomes corrosion wear. The friction coefficient of the sandwich structured coating after salt spray corrosion is slightly lower than the dry friction coefficient, but the weight of the wear loss is lower than that under dry condition.

Similar content being viewed by others

References

Rapouch J. Degradation of Cr3C2-NiCr Coating Prepared by the HVOF Technique[J]. Koroze a ochrana materiálu, 2013, 57(3): 82–86

Lekatou A, Zois D, Karantzalis A E, et al. Electrochemical Behaviour of Cermet Coatings with a Bond Coat on Al7075: Pseudopassivity, Localized Corrosion and Galvanic Effect Considerations in a Saline Environment[J]. Corrosion Science, 2010, 52(8): 2616–2635

Edrisy A, Perry T, Cheng Y T, et al. Wear of Thermal Spray Deposited Low Carbon Steel Coatings on Aluminum Alloys[J]. Wear, 2001, 251(1): 1023–1033

Sarcar MMM, Suman KNS, Kamaluddin S. Tribological and Corrosion Behavior of HVOF Sprayed WC-Co, NiCrBSi and Cr3C2-NiCr Coatings and Analysis using Design of Experiments[J]. Materials Today: Proceedings, 2015, 2(4): 2654–2665

Matthews S, James B, Hyland M. The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: Part 2-Heat Treated Coatings[J]. Surface and Coatings Technology, 2009, 203(8): 1094–1100

Matthews S, James B, Hyland M. The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: Part 1-As Sprayed Coatings[J]. Surface and Coatings Technology, 2009, 203(8): 1086–1093

Murthy JKN, Venkataraman B. Abrasive Wear Behaviour of WCCoCr and Cr3C2-20 (NiCr) Deposited by HVOF and Detonation Spray Processes[J]. Surface and Coatings Technology, 2006, 200(8): 2642–2652

Wirojanupatump S, Shipway P H, McCartney D G. The Influence of HVOF Powder Feedstock Characteristics on the Abrasive Wear Behaviour of CrxCy-NiCr Coatings[J]. Wear, 2001, 249(9): 829–837

Roy M, Pauschitz A, Wernisch J, et al. The Influence of Temperature on the Wear of Cr3C2-25 (Ni20Cr) Coating-Comparison Between Nanocrystalline Grains and Conventional Grains[J]. Wear, 2004, 257(7): 799–811

Ji GC, Li C J, Wang YY, et al. Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating[J]. Surface and Coatings Technology, 2006, 200(24): 6749–6757

El Rayes MM, Abdo HS, Khalil KA. Erosion-Corrosion of Cermet Coating[J]. International Journal of Electrochemical Science, 2013, 8: 1117–1137

Toma D, Brandl W, Marginean G. Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings[J]. Surface and Coatings Technology, 2001, 138(2): 149–158

Zavareh MA, Sarhan AADM, Razak BBA, et al. The Tribological and Electrochemical Behavior of HVOF Sprayed Cr3C2-NiCrCeramic Coating on Carbon Steel[J]. Ceramics International, 2015, 41(4): 5387–5396

Zavareh MA, Sarhan AAD, Razak B, et al. Electrochemical Characterizations of Different Ceramic Composite Coatings on Carbon Steel Piping Using High Velocity Oxy-Fuel Spray[C]. In: Proceedings of the World Congress on Engineering and Computer Science, WCECS, San Francisco, USA, 2014, 2: 22–24

Brezinová J, Guzanová A, Mamuzic I. Study of Wear Resistance of Coatings Deposited by High Velocity Oxygen Fuel (HVOF) Technology[J]. Acta Metallurgica Slovaca, 2012, 18(1): 20–27

Lekatou A, Regoutas E, Karantzalis AE. Corrosion Behaviour of Cermet-Based Coatings with a Bond Coat in 0.5 M H2SO4[J]. Corrosion Science, 2008, 50(12): 3389–3400

Dent AH, Horlock AJ, McCartney DG, et al. Microstructural Characterisation of a Ni-Cr-BC Based Alloy Coating Produced by High Velocity Oxy-Fuel Thermal Spraying[J]. Surface and Coatings Technology, 2001, 139(2): 244–250

Legg KO, Graham M, Chang P, et al. The Replacement of Electroplating[J]. Surface and Coatings Technology, 1996, 81(1): 99–105

Chatha SS, Sidhu HS, Sidhu BS. The Effects of Post-Treatment on the Hot Corrosion Behavior of the HVOF Sprayed Cr3C2-NiCr Coating[J]. Surface and Coatings Technology, 2012, 206(19): 4212–4224

Hong S, Wu Y, Wang Q, et al. Microstructure and Cavitation–Silt Erosion Behavior of High-Velocity Oxygen-Fuel (HVOF) Sprayed Cr3C2-NiCr Coating[J]. Surface and Coatings Technology, 2013, 225: 85–91

Staia MH, Suarez M, Chicot D, et al. Cr VPS Thermal Spray Coatings as Candidate for Chromium Replacement[J]. Surface and Coatings Technology, 2013, 220: 225–231

Fervel V, Normand B, Coddet C. Tribological Behavior of Plasma Sprayed Al2O3-Based Cermet Coatings[J]. Wear, 1999, 230(1): 70–77

Pantelis DI, Psyllaki P, and Alexopoulos P. Tribological Behaviour of Plasma-Sprayed Al2O3 Coatings under Severe Wear Conditions[J]. Wear, 2000, 237(2): 197–204

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the High-Tech Research and Development Program of China (No. 2012AA09A203), the Fundmental Research Funds for the Central Universities (No.15CX06061A) and the Postgraduate Innovation Project of China University of Petroleum (East China) (No. YCXJ2016059)

Rights and permissions

About this article

Cite this article

Bai, Y., Li, X., Xing, L. et al. Effect of salt spray corrosion on tribological properties of HVOF sprayed NiCr-Cr3C2 coating with intermediate layer. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 292–298 (2017). https://doi.org/10.1007/s11595-017-1595-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1595-9