Abstract

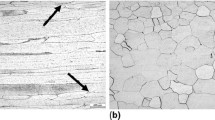

Power loss of Fe-3%Si grain-oriented silicon steel was measured after ball scribing with different spacing using a self-designed tool. Three different sections of power loss, including hysteresis loss, abnormal loss, and eddy current loss, were measured and calculated, respectively. The loss variation and ratio were analyzed based on the experimental data. At 1.0 T, hysteresis loss of tested steel with scribing spacing of 8 mm descends by 8.2% compared to samples without scribing, which is similar to the total loss variation, and abnormal loss descends by 16.8%. At 1.0 T, hysteresis loss ratio of the steel with scribing spacing of 16 mm ascends from 55.7% to 57.9%, and eddy current loss increases from 17.4% to 24.1%, while abnormal loss descends from 26.9% to 23.7%. The experimental results show that the reduction of power loss after scribing is mainly due to decreasing of hysteresis loss and abnormal loss.

Similar content being viewed by others

References

Hu CZ, Zhang DM, Zhang LM. Fabrication of Fe-6. 5wt% Si Bulk by Spark Plasma Sintering[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2005, 20(1): 72–74

Li CS, Yang H, Wang YF, et al. Texture of Cold Rolled Strip for Fe-3Si Steel Produced by Thin Slab Casting and Rolling[J]. J. Iron. Steel Res. Int., 2011, 18(3): 40–46

Bottauscio O, Chiampi M, Chiarabaglio D, et al. Use of Grain-oriented Materials in Low-frequency Magnetic Shielding[J]. J. Magn. Magn. Mater., 2000, 215-216(2): 130–132

Kumano T, Haratani T, Ushigami Y. The Improvement of Primary Texture for Sharp Goss Orientation on Grain Oriented Silicon Steel[J]. ISIJ Int., 2003, 43(5): 736–745

Imafuku M, Suzuki H, Akita K, et al. Effects of Laser Irradiation on Iron Loss Reduction for Fe–3%Si Grain-oriented Silicon Steel[J]. Acta Mater., 2005, 53(4): 939–945

Moses AJ. Energy Efficient Electrical Steels: Magnetic Performance Prediction and Optimization[J]. Scr. Mater., 2012, 67(6): 560–565

Wang H, Li CS, Zhu T. Hard Magnetization Direction and its Relation with Magnetic Permeability of Highly Grain-oriented Electrical Steel[J]. Int. J. Miner. Metall. Mater., 2014, 21(11): 1077–1082

Weidenfeller B, Anhalt M. Effect of Laser Treatment on High and Low Induction Loss Components of Grain Oriented Iron-silicon Sheets[J]. J. Magn. Magn. Mater., 2010, 322(1): 69–72

Gheorghies C, Doniga A. Evolution of Texture in Grain Oriented Electrical Steels[J]. J. Iron. Steel Res. Int., 2009, 16(4): 78–83

Zhmetko D N. The Dynamics of the Sandwich Domain Structure in 3%Si-Fe Sheets[J]. J. Magn. Magn. Mater., 2004, 279(2-3): 375–388

Beckley P. Electrical Steels for Rotating Machines[M]. Glasgow: Bell & Bain Ltd. 2002. 19–30

Snell D, Beckley P. Domain Refinement of High-permeability Grainoriented Electrical Steel Using Low-friction Ball Units[J]. J. Magn. Magn. Mater., 1994, 133(1-3): 167–169

Wang H, Li CS, Zhu T, et al. Effect of Ball Scribing on Relative Permeability of Grain-oriented Electrical Steel[J]. Acta Metall. Sinica, 2013, 26(6): 420–426

Boglietti A, Cavagnino A. Iron Loss Prediction with PWM Supply: An Overview of Proposed Methods from an Engineering Application Point of View[J]. Electr. Power Syst. Res., 2010, 80(6): 1121–1127

Wang H, Li CS, Zhu T, et al. Effect of Ball Scribing on Magnetic Barkhausen Noise of Grain-oriented Electrical Steel[J]. J. Mater. Sci. Technol., 2013, 29(7): 673–677

Kollár P, Z, Füzer J, et al. Power Loss Separation in Febased Composite Materials[J]. J. Magn. Magn. Mater., 2013, 237(2): 146–150

Bülow F, Eriksson S, Bernhoff H. No-load Core Loss Prediction of PM Generator at Low Electrical Frequency[J]. Renewable Energy, 2012, 43(3): 389–392

Broddefalk A, Lindenmo M. Dependence of the Power Losses of a Nonoriented 3% Si-steel on Frequency and Gauge[J]. J. Magn. Magn. Mater., 2006, 304(3): e586–e588

Wang H, Li CS, Huo G, et al. Effect of Ball Scribing on Iron Loss of CGO and HGO Electrical Steel[J]. J. Harbin Inst. Technol. (New Series), 2013, 20(3): 99–103

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China(Nos.51174057 and 51404159), the National High Technology Research and Development Program (No.2012AA03A503) and Research Fund for the Doctoral Program of Higher Education of China (No.20130042110040)

Rights and permissions

About this article

Cite this article

Wang, H., Li, C., Zhan, J. et al. Effect of ball scribing on power loss separation of Fe-3%Si grain-oriented silicon steel. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 435–439 (2016). https://doi.org/10.1007/s11595-016-1388-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1388-6