Abstract

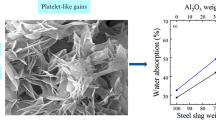

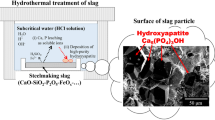

This study aimed to improve the hydraulic potential properties of the slag. Therefore, a method of dynamic hydrothermal synthesis was applied to synthesize calcium silicate hydrate. The phases and nanostructures were characterized by XRD, FTIR, TEM, and BET nitrogen adsorption. The influence of alkalinity of steel slag on its structures and properties was discussed. The experimental results show that, the main product is amorphous calcium silicate hydrate gel with flocculent or fibrous pattern with a BET specific surface area up to 77 m2/g and pore volume of 0.34 mL/g. Compared with low alkalinity steel slag, calcium silicate hydrate synthesized from higher alkalinity steel slag is prone to transform to tobermorite structure.

Similar content being viewed by others

References

Meng HD, Liu L. Fractal Characteristics of Granularity Distribution of Ground Steel Slag[J]. Cem. Eng., 2009, 6: 23–29

Wu SP, Xue YJ, Ye QS, et al. Utilization of Steel Slag as Aggregates for Stone Mastic Asphalt (SMA) Mixtures[J]. Build. Environ., 2007, 42: 2 580–2 585

Zhang L, Wang F, Chen X. Exploration on the Utilization and Development of Steel Slag[J]. iron & Steel Scrap of China, 2006, 1: 42–44

Li CH. Study on the Development and Prospect of Recycling Technology of Steel Slag in China [J]. WisCo Tech., 2010, 48,(4): 51–54

Wang Q, Yan PY, Feng JW. A Discussion on Improving Hydration Activity of Steel Slag by Altering Its Mineral Compositions [J]. J. Hazard. Mater., 2011, 186: 1 070–1 075

Mason B. The Constitution of Basic Open-heath Slag [J]. J. Iron and Steel Inst., 1994, 11: 69

Ouyang D, Xie YP, He JY. Composition, Mineral Morphology and Cementitious Properties of Converter Slag [J]. J. Chin. Ceram. Soc., 1991, 19,(6): 488–494

Xu GL, Qian GR, Lai ZY, et al. Study of Low-alkalinity Steel Slag Blended Oil Well Cement and Geothermal Cement Chemical Composition, Mineral Phase and Mineral Characteristic of Lowalkalinity Steel Slag [J]. J. Southwest. Inst. Tech., 2000, 15,(1): 10–14

Bowker JC, Lupis CP, Flinn PA. Structure Studies of Slags by Mössbauer Spectroscopy [J]. Can. Metall. Q., 1981, 20,(1): 69–78

Shen WG, Zhou MK, Ma W, et al. Investigation on the Application of Steel-slag-fly Ash Phosphogypsum Solidified Material as Road Base Material [J]. J. Hazard. Mater., 2009, 164: 99–104

Wang Q, Yan PY. Hydration Properties of Basic Oxygen Furnace Steel Slag [J]. Constr. Build. Mater., 2010, 24: 1 134–1 140

Kriskova L, Pontikes Y, Cizer O, et al. Effect of Mechanical Activation on the Hydraulic Properties of Stainless Steel Slag [J]. Cem. Concr. Res., 2012, 42: 778–788

Wang Q. Research Progress in Activation of Steel Slag Activity [J]. Ready-mixed Concr., 2010, (5): 26–28

Ke CJ, Su DG. Study on Activation for Steel-slag with Lower Alkalinity in Hydrothermal Condition [J]. Multipurpose Util. Miner. Resour., 2004. 12,(6): 40–44

Qian GR, Sun DD, Tay HH, et al. Autoclave Properties of Kirschsteinite — based steel slag [J]. Cem. Concr. Res., 2002, 32: 1 377–1 382

Wang SP, Peng XQ, Tang LP, et al. Influence of Inorganic Admixtures on the 11 Å-tobermorite Formation Prepared from Steel Slags: XRD and FTIR Analysis [J]. Constr. Build. Mater., 2014,(60): 42–47

Peng XQ, Gu SY, Huang T, et al. Reinforcement of Hydrated Calcium Silicate Powder to Silicon Rubber [J]. J. Civ., Archit. & Environ. Eng., 2010, 32,(5): 109–113

Zhang XX, Wei GS, Yu F. Thermal Radiative Properties of Xonolite Insulation Materials [J]. J. Therm. Sci., 2005, 14,(3): 281–284

Jing ZZ, Jin FM, Yamasaki N, et al. Hydrothermal Synthesis of a Novel Tobermorite-based Porous Material from Municipal Incineration Bottom Ash [J]. Ind. Eng. Chem. Res., 2007, 46: 2 657–2 660

Yang NR, Yue WH. Handbook of Microscopy of Inorganic Nonmetallic Materials [M]. Wuhan, Wuhan University of Technology. 2000: 65–90

Peng XQ, He LJ, Liu YM. Hydrated Calcium Silicate with Nm-order Size Manufactured by Using Dynamic Autoclaved Technology [J]. J. Chongqing Univ. (Nat. Sci. Ed.). 2005, 28,(5): 59–62

Ke CJ. Hydrothermal Performance and Its Mechanism of Low Alkalinity Steel Slag in Autoclaved Condition [J]. J. Build. Mater., 2007, 10,(2): 142–147

Mostafa NY, Kishar EA, Abo-El-Enein SA. FTIR Study and Cation Exchange Capacity of Fe3+ and Mg2+ -substituted Calcium Silicate Hydrates [J]. J. Alloy. Compd., 2009, 473: 538–542

Yuan RZ, Tan DL. Study on Surface Characteristic of Hydrated Calcium Silicates [J]. J. Chin. Ceram. Soc., 1988, 16,(6): 489–493

Cang H, Wang ZY, Zhang GC, et al. Effect of Surface Morphology of Fine Quartz on the Hollow Secondary Particles of Xonotlite [J]. J. Inorganic Mater., 1999, 14,(3): 431–436

Siauciunas R, Baltakys. Formation of Gyrolite During Hydrothermal Synthesis in the Mix-tures of CaO and Amorphous SiO2 or Quartz [J]. Cem. Concr. Res., 2004, 34: 2 029–2 036

Black L, Garbev K, Beuchle G, et al. X-ray Photoelectron Spectroscopic Investigation of Nanocrystalline Calcium Silicate Hydrates Synthsised by Reactive Milling [J]. Cem. Concr. Res., 2006, 6: 1 023–1 030

Richardson IG. Tobermorite/jennite- and Tobermorite/Calcium Hydroxide-based Models for the Structure of C-S-H: Applicability to Hardened Pastes of Tricalcium Silicate, Dicalcium Silicate, Portland Cement, and Blends of Portlandcement with Blast-furnace Slag, Metakaolin, or Silica Fume [J]. Cem. Concr. Res., 2004, 34: 1 733–1 777

Yang Q. Analysis on Microstructure and Primary Exploring of Contact Hardening Mechanism of C-S-H Superfine Powder Made with Hydrothermal Synthesis [D]. Chongqing: Chongqing University, 2008

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No. 50972171), the Project of International Science and Technology Cooperation (No.2009DFR50450), and the Large Equipment Fund of Chongqing University (No.2012061511)

Rights and permissions

About this article

Cite this article

Wang, S., Peng, X., Geng, J. et al. Synthesis of calcium silicate hydrate based on steel slag with various alkalinities. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 789–794 (2014). https://doi.org/10.1007/s11595-014-0998-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-014-0998-0