Abstract

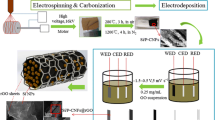

Due to the high theoretical specific capacity, silicon materials have been developed worldwide to meet the requirement of energy storage in lithium ion batteries. But the low conductivity and large volume expansion (300%) of Si usually cause poor cycling stability during charge/discharge processes. Here, a novel approach to fabricating a porous micro-structure of graphene wrapping silicon nanoparticles and polyaniline skeleton is proposed. The polyaniline skeleton grafted silicon nanoparticles is obtained by an in situ polymerization and the graphene sheets further wrap on the skeleton owing to an enhancement of π conjugation between the polyaniline and graphene. Thus, a 3D conductive and porous micro-structure is synthesized, which not only facilitates the electron and lithium ion transfer but also enhances the stability of structure during the volume expansion of Si. Benefiting from the advantages of structure, the electrode can deliver a reversible specific capacity of 2473 mAh g−1 at 0.2 A g−1 and 958 mAh g−1 at 10 A g−1. The electrode can keep a stable cycling with a capacity retention of 70% and 60% for 100 and 200 cycles at 25 °C, respectively. The method provides a promising strategy for solving the issues of silicon in lithium ion batteries.

Similar content being viewed by others

References

Minseong K, Sujong C, Sookyung J, Pilgun O, Jaephil C (2014) Elastica-silicon nanoparticle backboned graphene hybrid as a self-compacting anode for high-rate lithium ion batteries. ACS Nano 8:8591–8599. https://doi.org/10.1021/nn503294z

Li N, Jin SX, Liao QY, Cui H, Wang CX (2014) Encapsulated within graphene shell silicon nanoparticles anchored on vertically aligned graphene trees as lithium ion battery anodes. Nano Energy 5:105–115. https://doi.org/10.1016/j.nanoen.2014.02.011

Eom KS, Joshi T, Bordes A, Do I, Fuller TF (2014) The design of a Li-ion full cell battery using a nano silicon and nano multi-layer graphene composite anode. J Power Sources 249:118–124. https://doi.org/10.1016/j.jpowsour.2013.10.087

Liu XH, Zhang J, Si WP, Xi LX, Eichler B, Yan CL, Schmidt OG (2015) Sandwich nanoarchitecture of Si/reduced graphene oxide bilayer nanomembranes for Li-ion batteries with long cycle life. ACS Nano 9:1198–1205. https://doi.org/10.1021/nn5048052

Wu H, Chan G, Choi JW, Ryu I, Yao Y, McDoewell MT, Lee SW, Jackson A, Yang Y, Hu LB, Cui Y (2012) Stable cycling of double-walled silicon nanotube battery anodes through solid–electrolyte interphase control. Nat Nanotech 7:310–315. https://doi.org/10.1038/NNANO.2012.35

Zhao J, Lu ZD, Wang HT, Liu W, Lee HW, Yan K, Zhuo D, Lin DC, Liu N, Cui Y (2015) Artificial solid electrolyte interphase-protected LixSi nanoparticles: an efficient and stable prelithiation reagent for lithium-ion batteries. J Am Chem Soc 137:8372–8375. https://doi.org/10.1021/jacs.5b04526

Chan CK, Ruffo R, Hong SS, Cui Y (2009) Surface chemistry and morphology of the solid electrolyte interphase on silicon nanowire lithium-ion battery anodes. J Power Sources 189:1132–1140. https://doi.org/10.1016/j.jpowsour.2009.01.007

Xiang HF, Zhang K, Ji G, Lee JY, Zou CJ, Chen XD, Wu JS (2011) Graphene/nanosized silicon composites for lithium battery anodes with improved cycling stability. Carbon 49:1787–1796. https://doi.org/10.1016/j.carbon.2011.01.002

Park MH, Kim MG, Joo J, Kim K, Kim J, Ahn S, Cui Y, Cho J (2009) Silicon nanotube battery anodes. Nano Lett 9:3844–3847. https://doi.org/10.1021/nl902058c

Gunes F (2016) A direct synthesis of Si-nanowires on 3D porous graphene as a high performance anode material for Li-ion batteries. RSC Adv 6:1678–1685. https://doi.org/10.1039/c5ra18353g

Chabot V, Feng K, Park HW, Hassan FM, Elsayed AR, Yu AP, Xiao XC, Chen ZW (2014) Graphene wrapped silicon nanocomposites for enhanced electrochemical performance in lithium ion batteries. Electrochim Acta 130:127–134. https://doi.org/10.1016/j.electacta.2014.02.135

Cui LF, Hu L, Choi JW, Cui Y (2010) Light-weight free-standing carbon nanotube-silicon films for anodes of lithium ion batteries. ACS Nano 4:3671–3678. https://doi.org/10.1021/nn100619m

Zhou M, Cai TW, Pu F, Chen H, Wang Z, Zhang HY, Guan SY (2013) Graphene/carbon-coated Si nanoparticle hybrids as high-performance anode materials for Li-ion batteries. ACS Appl Mater Interfaces 5:3449–3455. https://doi.org/10.1021/am400521n

Zhang JY, Hou ZL, Zhang XM, Zhang LC, Li CB (2020) Delicate construction of Si@SiOx composite materials by microwave hydrothermal for lithium-ion battery anodes. Ionics 26:69–74. https://doi.org/10.1007/s11581-019-03204-0

LS Xiao YH Sehlleier S Dobrowolny F Mahlendorf A Heinzel C Schulz H Wiggers 2017 Novel Si-CNT/polyaniline nanocomposites as Lithium-ion battery anodes for improved cycling performance Materialstoday: Proceedings 4 S263 S268 https://doi.org/10.1016/j.matpr.2017.09.197

Chang JB, Huang XK, Zhou GH, Cui SM, Mao S, Chen JH (2015) Three-dimensional carbon-coated Si/rGO nanostructures anchored by nickel foam with carbon nanotubes for Li-ion battery applications. Nano Energy 15:679–687. https://doi.org/10.1016/j.nanoen.2015.05.020

Tokur M, Jin MY, Sheldon BW, Akbulut H (2020) Stress Bearing Mechanism of Reduced Graphene Oxide in Silicon-Based Composite Anodes for Lithium Ion Batteries. ACS Appl Mater Interfaces 12:33855–33869. https://doi.org/10.1021/acsami.0c10064

Lin HY, Li CH, Wang DY, Chen CC (2016) Chemical doping of a core–shell silicon nanoparticles@polyaniline nanocomposite for the performance enhancement of a lithium ion battery anode. Nanoscale 8:1280–1287. https://doi.org/10.1039/c5nr07152f

Ma TY, Yu XN, Cheng XL, Li HY, Zhu WT, Qiu XP (2017) Confined solid electrolyte interphase growth space with solid polymer electrolyte in hollow structured silicon anode for Li-ion batteries. ACS Appl Mater Interfaces 9:13247–12354. https://doi.org/10.1021/acsami.7b03046

Shan XJ, Cao Z, Zhu GB, Wang Y, Qu QT, Liu G, Zheng HH (2019) A trimethylol melamine functionalized polyvinyl alcohol network for high performance nano-silicon anodes. J Mater Chem A 7:26029–26038. https://doi.org/10.1039/C9TA09100A

Kummer M, Badillo JP, Schmitz A, Bremes HG, Winter M, Schulz C, Wiggers H (2014) Silicon/polyaniline nanocomposites as anode material for lithium ion batteries. J Electrochem Soc 161:A40–A45. https://doi.org/10.1149/2.020401jes

Mi HW, Li F, He CX, Chai XY, Zhang QL, Li CH, Li YL, Liu JH (2016) Three-dimensional network structure of silicon-graphene-polyaniline composites as high performance anodes for Lithium-ion batteries. Electrochim Acta 190:1032–1040. https://doi.org/10.1016/j.electacta.2015.12.182

Feng MY, Tian JH, Xie HM, Kang YL, Shan ZQ (2015) Nano-silicon/polyaniline composites with an enhanced reversible capacity as anode materials for lithium ion batteries. J Solid State Electr 19:1773–1782. https://doi.org/10.1007/s10008-015-2807-x

Tang H, Zhang J, Zhang YJ, Xiong QQ, Tong YY, Li Y, Wang XL, Gu CD, Tu JP (2015) Porous reduced graphene oxide sheet wrapped silicon composite fabricated by steam etching for lithium-ion battery application. J Power Sources 286:431–437. https://doi.org/10.1016/j.jpowsour.2015.03.185

Wang W, Favors Z, Li C, Liu C, Ye R, Fu C, Bozhilov K, Guo J, Ozkan M, Ozkan CS (2017) Silicon and carbon nanocomposite spheres with enhanced electrochemical performance for full cell lithium ion batteries. Sci Rep 7:44838. https://doi.org/10.1038/srep44838

He ZJ, Wu XW, Yi ZJ, Wang XY, Xiang YH (2017) Silicon/graphene/carbon hierarchical structure nanofibers for high performance lithium ion batteries. Mater Lett 200:128–131. https://doi.org/10.1016/j.matlet.2017.04.118

Tocoglu U, Hatipoglu G, Alaf M, Kayıs F, Akbulut H (2016) Electrochemical characterization of silicon/graphene/ MWCNT hybrid lithium-ion battery anodes produced via RF magnetron sputtering. Appl Surf Sci 389:507–513. https://doi.org/10.1016/j.apsusc.2016.07.135

Zhou M, Li XL, Wang B, Zhang YB, Ning J, Xiao ZC, Zhang XH, Chang YH, Zhi LJ (2015) High-performance silicon battery anodes enabled by engineering graphene assemblies. Nano Lett 15:6222–6228. https://doi.org/10.1021/acs.nanolett.5b02697

Bai XJ, Yu YY, Kung HH, Wang B, Jiang JM (2016) Si@SiOx/graphene hydrogel composite anode for lithium-ion battery. J Power Sources 306:42–48. https://doi.org/10.1016/j.jpowsour.2015.11.102

Liu ZJ, Guo PQ, Liu BL, Xie WH, Liu DQ, He DY (2017) Carbon-coated Si nanoparticles/reduced graphene oxide multilayer anchored to nanostructured current collector as lithium-ion battery anode. Appl Surf Sci 396:41–47. https://doi.org/10.1016/j.apsusc.2016.11.045

Wu H, Yu GH, Pan LJ, Liu NA, McDowell MT, Bao ZA, Cui Y (2013) Stable Li-ion battery anodes by in-situ polymerization of conducting hydrogel to conformally coat silicon nanoparticles. Nat. Commun. 4:1943. https://doi.org/10.1038/ncomms2941

Tian SY, Zhu GN, Tang YP, Xie XH, Wang Q, Ma YF, Ding GQ, Xie XM (2018) Three-dimensional cross-linking composite of graphene, carbon nanotubes and Si nanoparticles for lithium ion battery anode. Nanotechnology 29:125603. https://doi.org/10.1088/1361-6528/aaa84e

Tu JG, Hu LW, Wang W, Hou JG, Zhu HM, Jiao SQ (2013) In-situ synthesis of silicon/polyaniline core/shell and its electrochemical performance for lithium-ion batteries. J Electrochem Soc 160:A1916–A1921. https://doi.org/10.1149/2.003311jes

Chiboub N, Boukherroub R, Gabouze N, Moulay S, Naar N, Lamouri S, Sam S (2010) Covalent grafting of polyaniline onto aniline-terminated porous silicon. Opt Mater 32:748–752. https://doi.org/10.1016/j.optmat.2010.02.007

Wang X, Singh SS, Ma T, Lv C, Chawla N, Jiang HQ (2017) Quantifying electrochemical reactions and properties of amorphous silicon in a conventional lithium-ion battery configuration. Chem Mater 29:5831–5840. https://doi.org/10.1021/acs.chemmater.7b00701

Chen DD, Liao WJ, Yang Y, Zhao JB (2016) Polyvinyl alcohol gelation: A structural locking-up agent and carbon source for Si/CNT/C composites as high energy lithium ion battery anode. J Power Sources 315:236–241. https://doi.org/10.1016/j.jpowsour.2016.03.051

Wu CQ, Lin J, Chu RX, Zheng J, Chen YL, Zhang J, Guo H (2017) Reduced graphene oxide as a dual-functional enhancer wrapped over silicon/porous carbon nanofibers for high-performance lithium-ion battery anodes. J Mater Sci 52:7984–7996. https://doi.org/10.1007/s10853-017-1001-1

Yang Y, Wang ZX, Zhou Y, Guo HJ, Li XH (2017) Synthesis of porous Si/graphite/carbon nanotubes@C composites as a practical high-capacity anode for lithium-ion batteries. Mater Lett 199:84–87. https://doi.org/10.1016/j.matlet.2017.04.057

Zhang YG, Du N, Zhu SJ, Chen YF, Lin YF, Wu SL, Yang DR (2017) Porous silicon in carbon cages as high-performance lithium-ion battery anode. Electrochim Acta 252:438–445. https://doi.org/10.1016/j.electacta.2017.08.038

Li H, Lu CX, Zhang BP (2014) A straightforward approach towards Si@C/graphene nanocompositeand its superior lithium storage performance. Electrochim Acta 120:96–101. https://doi.org/10.1016/j.electacta.2013.12.048

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xie, X., Tian, S., Guo, W. et al. In situ polymerization of aniline to prepare porous micro-nanostructure anode of graphene wrapping silicon and polyaniline for lithium ion batteries. Ionics 28, 2203–2211 (2022). https://doi.org/10.1007/s11581-022-04486-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04486-7