Abstract

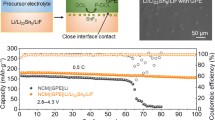

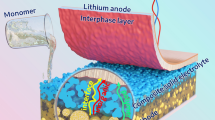

Lithium solid-state batteries (SSBs) with tantalum doped Li7La3Zr2O12 (LLZT) inorganic ceramic electrolytes have been attracting much interest for its extraordinary lithium ionic conductivity, non-flammability, and wide electrochemical window. However, poor solid–solid contact between the electrodes and electrolyte results in large interfacial resistance, which hinders its normal operation and practical application. Herein, triethylene glycol diacetate-2-propenoic acid butyl ester (TEGDA-BA) based gel polymer electrolytes (GPE) were fabricated and coated on both sides of spark plasma sintering (SPS)–derived LLZT pellet. GPE introduction not only provides intimate contact between solid electrolyte and electrodes but also avoids side reactions such as reduction of LLZT by lithium anode. Moreover, symmetric Li cell markedly reduced interfacial resistance and exhibited a critical current density up to 1.0 mA cm−2 at room temperature (25 °C), and it can also stably cycle at 0.5 mA cm−2 for over 277 h without Li dendrite formation. The assembled solid-state LiNi0.5Co0.2Mn0.3O2 (NCM523)/GPE–LLZT–GPE/Li battery exhibits high initial capacity (163.5 mAh g−1) at 0.2 C. This work provides a facile method to reduce the interfacial resistance and demonstrates durable high-energy solid-state lithium metal batteries suitable for practical application.

Similar content being viewed by others

References

Hesse H, Schimpe M, Kucevic D, Jossen A (2017) Lithium–ion battery storage for the grid–a review of stationary battery storage system design tailored for applications in modern power grids. Energies 10(12):2107

Dunn B, Kamath H, Tarascon J (2011) Electrical energy storage for the grid: a battery of choices. Science 334(6058):928–935

Diouf B, Pode R (2015) Potential of lithium–ion batteries in renewable energy. Renew Energy 76:375–380

Goodenough JB, Kim Y (2010) Challenges for rechargeable Li batteries. Chem Mater 22(3):587–603

Manthiram A, Yu XW, Wang SF (2017) Lithium battery chemistries enabled by solid–state electrolytes. Nat Rev Mater 2(4):1–16

Xu L, Tang S, Cheng Y, Wang KY, Liang JY, Liu C, Cao YC, Wei F, Mai LQ (2018) Interfaces in solid–state lithium batteries. Joule 2(10):1991–2015

Jiao SH, Zheng JM, Li QY, Li X, Engelhard M, Cao RG, Zhang JG, Xu W (2018) Behavior of lithium metal anodes under various capacity utilization and high current density in lithium metal batteries. Joule 2(1):110–124

Monroe C, Newman J (2005) The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J Electrochem Soc 152(2):A396

Tikekar M, Choudhury S, Tu ZY, Archer L (2016) Design principles for electrolytes and interfaces for stable lithium–metal batteries. Nat Energy 1(9):1–7

Porz L, Swamy T, Sheldon B, Rettenwander D, Fromling T, Thaman H, Berendts S, Uecker R, Carter W, Chiang YM (2017) Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv Energy Mater 7:1701003

Han FD, Westover A, Yue J, Fan XL, Wang F, Chi MF, Leonard D, Dudney N, Wang H, Wang CS (2019) High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat Energy 4:187–196

Famprikis T, Canepa P, Dawson J, Islam M, Masquelier C (2019) Fundamentals of inorganic solid-state electrolytes for batteries. Nat Mater 18(12):1278–1291

Jung YC, Lee SM, Choi JH, Jang SS, Kim DW (2015) All solid–state lithium batteries assembled with hybrid solid electrolytes. J Electrochem Soc 162(4):A704

Lu Z, Yu J, Wu JX, Effat M, Kwok S, Lyu YQ, Yuen M, Ciucci F (2019) Enabling room–temperature solid–state lithium–metal batteries with fluoroethylene carbonate–modified plastic crystal interlayers. Energy Storage Mater 18:311–319

Cheng Q, Li AJ, Li N, Li S, Zangiabadi A, Li TD, Huang WL, Li AC, Jin TW, Song QQ, Xu WH, Ni N, Zhai HW, Dontigny M, Zaghib K, Chuan XY, Su D, Yan K, Yang Y (2019) Stabilizing solid electrolyte–anode interface in Li–metal batteries by boron nitride–based nanocomposite coating. Joule 3(6):1510–1522

Duan H, Chen WP, Fan M, Wang WP, Yu L, Tan SJ, Chen X, Zhang Q, Xin S, Wan LJ, Guo YG (2020) Building an air stable and lithium deposition regulable garnet interface from moderate–temperature conversion chemistry. Angew Chem Int Ed. https://doi.org/10.1002/anie.202003177

Jin YM, Liu CJ, Zong X, Li D, Fu MY, Tan SP, Xiong YP, Wei JH (2020) Interface engineering of Li1.3Al0.3Ti1.7(PO4) 3 ceramic electrolyte via multifunctional interfacial layer for all–solid–state lithium batteries. J Power Sources 460:228125

Wang CS, Zhang XW, Appleby A (2004) Solvent–free composite PEO–ceramic fiber/mat electrolytes for lithium secondary cells. J Electrochem Soc 152(1):A205

Prasanth R, Aravindan V, Srinivasan M (2012) Novel polymer electrolyte based on cob–web electro–spun multi component polymer blend of polyacrylonitrile/poly (methyl methacrylate)/polystyrene for lithium ion batteries–preparation and electrochemical characterization. J Power Sources 202:299–307

Li Y, Wong KW, Dou Q, Zhang W, Wang L, Ng KM (2017) A highly elastic and flexible solid-state polymer electrolyte based on ionic liquid–decorated PMMA nanoparticles for lithium batteries. New J Chem 41(21):13096–13103

Xiao YH, Wang Y, Bo SH, Kim JC, Miara L, Ceder G (2020) Understanding interface stability in solid-state batteries. Nat Rev Mater 5(2):105–126

Samson A, Hofstetter K, Bag S, Thangadurai V (2019) A bird’s–eye view of Li–stuffed garnet–type Li7La3Zr2O12 ceramic electrolytes for advanced all–solid–state Li batteries. Energy Environ Sci 12(10):2957–2975

Ohta S, Komagata S, Seki J, Saeki T, Morishita S, Asaoka T (2013) All–solid–state lithium ion battery using garnet–type oxide and Li3BO3 solid electrolytes fabricated by screen–printing. J Power Sources 238:53–56

Lu YY, Tu ZY, Archer L (2014) Stable lithium electrodeposition in liquid and nano porous solid electrolytes. Nat Mater 13(10):961–969

Wang QJ, Song WL, Fan LZ, Song Y (2015) Flexible, high–voltage and free–standing composite polymer electrolyte membrane based on triethylene glycol diacetate–2–propenoic acid butyl ester copolymer for lithium–ion batteries. J Membr Sci 492:490–496

Zhou D, Shanmukaraj D, Tkacheva A, Armand M, Wang GX (2019) Polymer electrolytes for lithium–based batteries: advances and prospects. Chem 5(9):2326–2352

Wang QJ, Song WL, Fan LZ, Shi Q (2015) Effect of polyacrylonitrile on triethylene glycol diacetate–2–propenoic acid butyl ester gel polymer electrolytes with interpenetrating crosslinked network for flexible lithium ion batteries. J Power Sources 295:139–148

Thangadurai V, Weppner W (2005) Li6ALa2Ta2O12 (A= Sr, Ba): novel garnet-like oxides for fast lithium ion conduction. Adv Funct Mater 15(1):107–112

Awaka J, Kijima N, Hayakawa H, Akimoto J (2009) Synthesis and structure analysis of tetragonal Li7La3Zr2O12 with the garnet–related type structure. J Solid State Chem 182(8):2046–2052

Awaka J, Takashima A, Kataoka K, Kijima N, Idemoto Y, Akimoto J (2011) Crystal structure of fast lithium–ion–conducting cubic Li7La3Zr2O12. Chem Lett 40:60–62

Chung H, Kang B (2017) Mechanical and thermal failure induced by contact between a Li1.5Al0.5Ge1.5(PO4)3 solid electrolyte and Li metal in an all–solid–state Li cell. Chem Mater 29(20):8611–8619

Liu YJ, Li C, Li BJ, Song HC, Cheng Z, Chen MR, He P, Zhou HS (2018) Germanium thin film protected lithium aluminum germanium phosphate for solid–state Li batteries. Adv Energy Mater 8(16):1702374

Ong SP, Mo YF, Richards W, Miara L, Lee HS, Ceder G (2013) Phase stability, electrochemical stability and ionic conductivity of the Li10±1MP2X12 (M= Ge, Si, Sn, Al or P, and X = O, S or Se) family of superionic conductors. Energy Environ Sci 6:148–156

Kotobuki M, Song SF, Takahashi R, Shunichi Y, Lu L (2017) Improvement of Li ion conductivity of Li5La3Ta2O12 solid electrolyte by substitution of Ge for Ta. J Power Sources 349:105–110

Zhou D, Fan LZ, Fan HH, Shi Q (2013) Electrochemical performance of trimethylolpropane trimethylacrylate–based gel polymer electrolyte prepared by in situ thermal polymerization. Electrochim Acta 89:334–338

Fan H, Li H, Fan LZ, Shi Q (2014) Preparation and electrochemical properties of gel polymer electrolytes using triethylene glycol diacetate–2–propenoic acid butyl ester copolymer for high energy density lithium–ion batteries. J Power Sources 249:392–396

Guo HJ, Su JM, Zha WP, Xiu TP, Song Z, Badding M, Jin J, Wen ZY (2020) Achieving high critical current density in Ta–doped Li7La3Zr2O12/MgO composite electrolytes. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.157222

Bernuy-Lopez C, Manalastas W Jr, Lopez del Amo J, Aguadero A, Aguesse F, Kilner J (2014) Atmosphere controlled processing of Ga–substituted garnets for high Li–ion conductivity ceramics. Chem Mater 26(12):3610–3617

Rettenwander D, Redhammer G, Preishuber-Pflugl F, Cheng L, Miara L, Wagner R, Welzl A, Suard E, Doeff M, Wilkening M, Fleig J, Amthauer G (2016) Structural and electrochemical consequences of Al and Ga co–substitution in Li7La3Zr2O12 solid electrolytes. Chem Mater 28(7):2384–2392

Du FM, Zhao N, Li YQ, Chen C, Liu ZW, Guo XX (2015) All solid-state lithium batteries based on lamellar garnet–type ceramic electrolytes. J Power Sources 300:24–28

Bai LX, Xue WD, Xue YW, Qin HX, Li Y, Li Y, Sun JL (2018) Interfacial ion-transport mechanism of Li7(Al0.1)La3Zr2O12 solid electrolyte modified by using a spark plasma sintering method. Chem Electro Chem 5(24):3918–3925

Ahmad S, Saxena T, Ahmad S, Agnihotry S (2006) The effect of nanosized TiO2 addition on poly(methylmethacrylate) based polymer electrolytes. J Power Sources 159(1):205–209

Ji X, Hou S, Wang PF, He XZ, Piao N, Chen J, Fan XL, Wang CS (2020) Solid–state electrolyte design for lithium dendrite suppression. Adv Mater 32(46):2002741

Song SF, Deng F, Zhai YF, Yang GM, Yao JY, Li S, Hu N, Tang WP, Wen ZY, Lu L (2020) Ultrathin, dense, hybrid polymer/ceramic gel electrolyte for high energy lithium metal batteries. Mater Lett 279:128480

Shi CM, Wang TY, Liao XB, Qie BY, Yang PF, Chen MJ, Wang X, Srinivasan A, Cheng Q, Ye Q, L AC, Chen X, Yang Y (2019) Accordion–like stretchable Li–ion batteries with high energy density. Energy Storage Mater 17:136–142

Liao XB, Shi CM, Wang TY, Qie BY, Chen YL, Yang PF, Chen Q, Zhai HW, Chen MJ, Wang X, Chen X, Yang Y (2019) High–energy–density foldable battery enabled by zigzag–like design. Adv Energy Mater 9(4):1802998

Acknowledgements

The authors thank Prof. Lizhen Fan at University of Science and Technology Beijing for performing the solid-state battery measurement.

Funding

This work was supported by the National Natural Science Foundation of China (51702012) and the Fundamental Research Funds for the Central Universities (FRF-TP-18-022A2). Dr. Mingpeng Yu was also supported by the China Scholarship Council (CSC) (File No. 201802180015). The authors Wenqi Wang, Shuchang Hao, Hao Chen and Yu Huang gratefully acknowledge the financial support of SRTP program (Grant No.202021014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOC 532 kb).

Rights and permissions

About this article

Cite this article

Zhao, B., Feng, X., Yu, M. et al. Interfacial modification enabled room temperature solid-state lithium–metal batteries. Ionics 27, 1569–1578 (2021). https://doi.org/10.1007/s11581-021-03928-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-03928-y