Abstract

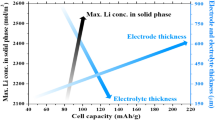

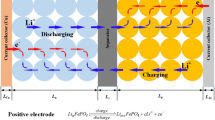

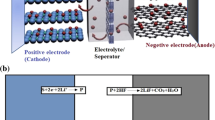

Capacity is one of the key parameters to characterize the performances of lithium-ion batteries. Heat generation analysis is essential to evaluate the safety of batteries. To figure out the effects of electrode thickness on capacity fade and thermal behaviors, a capacity fading model is proposed considering reaction kinetics and mass transfer processes on solid electrolyte interface (SEI) layers coupled with thermal evolution. Simulations are conducted on seven LiFePO4 batteries with variable electrode thicknesses. Results show that, with the increase of electrode thickness, the capacity losses of batteries deteriorate, and the total heat generation aggravates. For the battery with thick electrode, both the polarization overpotential and the gradient of lithium ion concentrations on particle surfaces of active materials increase on the edges, and then decrease perpendicularly to the cathodes. Under the adiabatic conditions, the temperature of battery (with anode 68 μm and cathode 140 μm) is increased to over 130 °C at the sixth cycle. The temperature of batteries declines when discharging in the beginning and then rises, which is noticeable for the batteries with thin electrodes. The proposed model and the simulation results would provide deep insights into both design and operation of batteries.

Similar content being viewed by others

Abbreviations

- a s :

-

Active area per unit electrode volume, m2 m−3

- c :

-

Concentration, mol m−3

- c p :

-

Specific heat capacity, J kg−1 K−1

- D :

-

Diffusion coefficient, m2 s−1

- E a :

-

Active energy, kJ mol−1

- f ± :

-

Electrolyte activity coefficient

- F :

-

Faradays constant, 98465 C mol−1

- h :

-

Convective heat transfer coefficient, W m−2 K−1

- i :

-

Reaction current, A m−2

- i app :

-

Applied current density, A m−2

- i loc :

-

Local current density, A m−2

- i Li :

-

Reaction current for intercalation reaction, A m−2

- i side :

-

Reaction current for side reaction, A m−2

- k :

-

Reaction rate constant, m s−1

- L :

-

Thickness, μm

- M :

-

Molecular weight, kg mol−1

- q rea :

-

Reaction heat generation, W m−3

- q act :

-

Irreversible polarization heat generation, W m−3

- q ohm :

-

Ohmic heat generation, W m−3

- r :

-

Radial coordinate, m

- R :

-

Universal gas constant, 8.314 J mol−1 K−1

- R s :

-

Particle radius, m

- R SEI :

-

Resistance of the SEI layer, Ω m2

- S a :

-

Active area per unit electrode volume, m2 m−3

- SOC :

-

States of charge

- t :

-

Time, s

- \( {t}_{+}^0 \) :

-

Transference number

- T :

-

Temperature, K

- u :

-

Growth rate of the SEI layer, m s−1

- U :

-

Open circuit voltage (OCV), V

- x :

-

x-coordinate, m

- β :

-

Charge transfer coefficient.

- δ :

-

Thickness of the SEI layer, nm

- ε :

-

Porosity

- η :

-

Overpotential, V

- λ :

-

Thermal conductivity, W m−1 K−1

- ρ :

-

Density, kg m−3

- σ :

-

Ionic conductivity, S m−1

- ϕ :

-

Voltage, V

- υ :

-

The product of thermodynamic factor

- eff :

-

Effective

- 1 :

-

Solid phase

- 2 :

-

Electrolyte phase

- EC :

-

Ethylene carbonate in electrolyte

- j :

-

Anode, cathode or separator

- max :

-

Maximum

- n :

-

Anode

- p :

-

Cathode

- s :

-

Separator

- side :

-

Side reaction

- SEI :

-

SEI layer

References

Purvins A, Zubaryeva A, Llorente M, Tzimas E, Mercier A (2011) Challenges and options for a large wind power uptake by the European electricity system. Appl Energy 88(5):1461–1469. https://doi.org/10.1016/j.apenergy.2010.12.017

Kil KC, Paik U (2015) Lithium salt of carboxymethyl cellulose as an aqueous binder for thick graphite electrode in lithium ion batteries. Macromol Res 23(8):719–725. https://doi.org/10.1007/s13233-015-3094-1

Franco AA (2013) Multiscale modelling and numerical simulation of rechargeable lithium ion batteries: concepts, methods and challenges. RSC Adv 3(32):13027–13058

Zheng H, Li J, Song X, Liu G, Battaglia VS (2012) A comprehensive understanding of electrode thickness effects on the electrochemical performances of li-ion battery cathodes. Electrochim Acta 71:258–265. https://doi.org/10.1016/j.electacta.2012.03.161

Hamankiewicz B, Michalska M, Krajewski M, Ziolkowska D, Lipinska L, Korona K, Kaminska M, Czerwinski A (2014) The effect of electrode thickness on electrochemical performance of LiMn2O4 cathode synthesized by modified sol–gel method. Solid State Ionics 262:9–13. https://doi.org/10.1016/j.ssi.2013.08.010

Doyle M, Fuller TF, Newman J (1993) Modeling of calvanostatic charge and discharge of the lithium polymer insertion cell. J Electrochemical Soc 140(6):1526–1533. https://doi.org/10.1149/1.2221597

Zheng Q, Li X, Cheng Y, Ning G, Xing F, Zhang H (2014) Development and perspective in vanadium flow battery modeling. Appl Energy 132:254–266. https://doi.org/10.1016/j.apenergy.2014.06.077

Jokar A, Rajabloo B, Desilets M, Lacroix M (2016) Review of simplified pseudo-two-dimensional models of lithium-ion batteries. J Power Source 327:44–55. https://doi.org/10.1016/j.jpowsour.2016.07.036

Zhao R, Liu J, Gu J (2015) The effects of electrode thickness on the electrochemical and thermal characteristics of lithium ion battery. Appl Energy 139:220–229. https://doi.org/10.1016/j.apenergy.2014.11.051

Zheng HY, Tan L, Zhang L, Qu QT, Wan ZM, Wang Y, Shen M, Zheng HH (2015) Correlation between lithium deposition on graphite electrode and the capacity loss for LiFePO4/graphite cells. Electrochim Acta 173:323–330. https://doi.org/10.1016/j.electacta.2015.05.039

Wang FM, Wang HY, Yu MH, Hsiao YJ, Tsai Y (2011) Differential pulse effects of solid electrolyte interface formation for improving performance on high-power lithium ion battery. J Power Source 196(23):10395–10400. https://doi.org/10.1016/j.jpowsour.2011.08.045

Pinson MB, Bazant MZ (2013) Theory of SEI formation in rechargeable batteries: capacity fade, accelerated aging and lifetime prediction. J Electrochem Soc 160(2):A243–A250. https://doi.org/10.1149/2.044302jes

Ramadass P, Haran B, Gomadam PM, White R, Popov BN (2004) Development of first principles capacity fade model for li-ion cells. J Electrochemical Soc 151(2):A196–A203. https://doi.org/10.1149/1.1634273

Ning G, White RE, Popov BN (2006) A generalized cycle life model of rechargeable li-ion batteries. Electrochim Acta 51(10):2012–2022. https://doi.org/10.1016/j.electacta.2005.06.033

Ploehn HJ, Ramadass P, White RE (2004) Solvent diffusion model for aging of lithium-ion battery cells. J Electrochemical Soc 151(3):A456–A462. https://doi.org/10.1149/1.1644601

Xie YY, Li JY, Yuan C (2014) Multiphysics modeling of lithium ion battery capacity fading process with solid-electrolyte interphase growth by elementary reaction kinetics. J Power Source 248:172–179. https://doi.org/10.1016/j.jpowsour.2013.09.059

Ashwin TR, Chung YM, Wang J (2016) Capacity fade modelling of lithium-ion battery under cyclic loading conditions. J Power Sources 328:586–598. https://doi.org/10.1016/j.jpowsour.2016.08.054

Colclasure AM, Smith KA, Kee RJ (2011) Modeling detailed chemistry and transport for solid-electrolyte-interface (SEI) films in li–ion batteries. Electrochim Acta 58:33–43. https://doi.org/10.1016/j.electacta.2011.08.067

Zhang Y, Song W, Lin S, Feng Z (2014) Multiparameters model of the initial SOC considering the relaxation effect. ACS Sustain Chem Eng 2(4):599–605. https://doi.org/10.1021/sc400430e

Yan J, Xia B, Su Y, Zhou X, Zhang J, Zhang X (2008) Phenomenologically modeling the formation and evolution of the solid electrolyte interface on the graphite electrode for lithium-ion batteries. Electrochim Acta 53(24):7069–7078. https://doi.org/10.1016/j.electacta.2008.05.032

Lu P, Harris SJ (2011) Lithium transport within the solid electrolyte interphase. Electrochem Commun 13(10):1035–1037. https://doi.org/10.1016/j.elecom.2011.06.026

Tang M, Lu S, Newman J (2012) Experimental and theoretical investigation of solid-electrolyte-interphase formation mechanisms on glassy carbon. J Electrochemical Soc 159(11):A1775–A1785. https://doi.org/10.1149/2.025211jes

Safari M, Morcrette M, Teyssot A, Delacourt C (2009) Multimodal physics-based aging model for life prediction of li-ion batteries. J Electrochemical Soc 156(3):A145–A153. https://doi.org/10.1149/1.3043429

Basu S, Hariharan KS, Kolake SM, Song T, Sohn DK, Yeo T (2016) Coupled electrochemical thermal modelling of a novel li-ion battery pack thermal management system. Appl Energy 181:1–13. https://doi.org/10.1016/j.apenergy.2016.08.049

Ye Y, Shi Y, Tay AAO (2012) Electro-thermal cycle life model for lithium iron phosphate battery. J Power Sources 217:509–518. https://doi.org/10.1016/j.jpowsour.2012.06.055

Wu W, Xiao XR, Huang XS (2012) The effect of battery design parameters on heat generation and utilization in a li-ion cell. Electrochim Acta 83:227–240. https://doi.org/10.1016/j.electacta.2012.07.081

Valoen LO, Reimers JN (2005) Transport properties of LiPF6-based li-ion battery electrolytes. J Electrochemical Soc 152(5):A882–A891. https://doi.org/10.1149/1.1872737

Bernardi D, Pawlikowski E, Newman J (1985) A general energy balance for battery systems. J Electrochemical Soc 132(1):5–12. https://doi.org/10.1149/1.2113792

Xu M, Zhang ZQ, Wang X, Jia L, Yang LX (2015) A pseudo three-dimensional electrochemical-thermal model of a prismatic LiFePO4 battery during discharge process. Energy 80:303–317. https://doi.org/10.1016/j.energy.2014.11.073

Safari M, Delacourt C (2011) Modeling of a commercial graphite/LiFePO4 cell. J Electrochem Soc 158(5):A562–A571. https://doi.org/10.1149/1.3567007

Srinivasan V, Wang CY (2003) Analysis of electrochemical and thermal behavior of li-ion cells. J Electrochemical Soc 150(1):A98–A106. https://doi.org/10.1149/1.1526512

Gerver RE, Meyers JP (2011) Three-dimensional modeling of electrochemical performance and heat generation of lithium-ion batteries in tabbed planar configurations. J Electrochemical Soc 158(7):A835–A843. https://doi.org/10.1149/1.3591799

Wang J, Liu P, Hicks-Garner J, Sherman E, Soukiazian S, Verbrugge M, Tataria H, Musser J, Finamore P (2011) Cycle-life model for graphite-LiFePO4 cells. J Power Sources 196(8):3942–3948. https://doi.org/10.1016/j.jpowsour.2010.11.134

Jalkanen K, Karppinen J, Skogström L, Laurila T, Nisula M, Vuorilehto K (2015) Cycle aging of commercial NMC/graphite pouch cells at different temperatures. Appl Energy 154:160–172. https://doi.org/10.1016/j.apenergy.2015.04.110

Saw LH, Ye YH, Tay AAO (2013) Electrochemical-thermal analysis of 18650 lithium iron phosphate cell. Energy Conv Manag 75:162–174. https://doi.org/10.1016/j.enconman.2013.05.040

Wang Q, Ping P, Zhao X, Chu G, Sun J, Chen C (2012) Thermal runaway caused fire and explosion of lithium ion battery. J Power Sources 208:210–224. https://doi.org/10.1016/j.jpowsour.2012.02.038

Borodin O, Smith GD, Fan P (2006) Molecular dynamics simulations of lithium alkyl carbonates. J Phys Chem B 110(45):22773–22779. https://doi.org/10.1021/jp0639142

Safari M, Delacourt C (2011) Simulation-based analysis of aging phenomena in a commercial graphite/LiFePO4 cell. J Electrochemical Soc 158(12):A1436–A1447. https://doi.org/10.1149/2.103112jes

Acknowledgements

The authors gratefully acknowledge funding by the projects (No. 21676211 and No. 21606174) sponsored by the National Natural Science Foundation of China (NSFC). The authors also gratefully acknowledge funding by the China Postdoctoral Science Foundation (Grant 2016M592793).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 413 kb)

Rights and permissions

About this article

Cite this article

Huang, X., Ke, S., Lv, H. et al. A dynamic capacity fading model with thermal evolution considering variable electrode thickness for lithium-ion batteries. Ionics 24, 3439–3450 (2018). https://doi.org/10.1007/s11581-018-2476-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-018-2476-8