Abstract

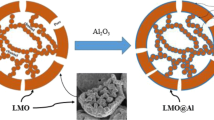

LiMnPO4/LiMn2O4 (LMP/LMO) composite cathodes with LMP coating on the surface of LMO were synthesized by hydrothermal method at 180 °C for 10 h. The crystal structures and microstructures were characterized via power X-ray diffraction (XRD), field emission scanning electron microscope (FE-SEM), and high-resolution transmission electron microscope (HRTEM). The electrochemical properties were characterized by cyclic voltammetry (CV) measurement and charge–discharge test. LMP/LMO composite cathodes exhibited higher discharge capacity and better cycle stability than the bare LiMn2O4 cathode. Taking both capacity and cycle ability into concern, 15 wt% LiMnPO4 that coated LiMn2O4 possessed the best performances. At 55 °C, it delivered an initial discharge capacity of 120.1 mAh g−1 and retained 97.1 % of the initial capacity after 100 cycles at 1 C rate.

Similar content being viewed by others

References

Thackeray MM, Johnson PJ, Depicciotto LA, Bruce PG, Goodenough JB (1984) Electrochemical extraction of lithium from LiMn2O4. Mater Res Bull 19:179–187

Li XF, Xu YL (2007) Novel method to enhance the cycling performance of spinel LiMn2O4. Electrochem Commun 9:2023–2026

Aurbach D, Levi MD, Gamulski K, Markovsky B, Salitra G, Levi E, Heider U, Heider L, Oesten R (1999) Capacity fading of Li x Mn2O4 spinel electrodes studied by XRD and electroanalytical techniques. J Power Sources 81:472–479

Yamane H, Inoue T, Fujita M, Sano M (2001) A causal study of the capacity fading of Li1.01Mn1.99O4 cathode at 80 °C, and the suppressing substances of its fading. J Power Sources 99:60–65

Shin YJ, Manthiram A (2004) Factors influencing the capacity fade of spinel lithium manganese oxides. J Electrochem Soc 151:A204–A208

Xu B, Qian DN, Wang ZY, Meng YS (2012) Recent progress in cathode materials research for advanced lithium ion batteries. Mater Sci Eng R 73:51–65

Lee JF, Tsai YW, Santhanam R, Hwang BJ (2003) Local structure transformation of nano-sized Al-doped LiMn2O4 sintered at different temperatures. J Power Sources 119:721–726

Zhao SL, Chen HY, Wen JB, Li DX (2009) Electrochemical properties of spinel LiCoxMn2−x O4 prepared by sol–gel process. J Alloys Compd 474:473–476

Brutti S, Gentili V, Reale P, Carbone L, Panero S (2011) Mitigation of the irreversible capacity and electrolyte decomposition in a LiNi0.5Mn1.5O4/nano-TiO2 Li-ion battery. J Power Sources 196:9792–9799

Li G, Ikuta H, Uchida T, Wakihara M (1996) The spinel phases LiM y Mn2−y O4 (M = Co, Cr, Ni) as the cathode for rechargeable lithium batteries. J Electrochem Soc 143:178–182

Li XW, Yang R, Cheng B, Hao Q, Xu HY, Yang J, Qian YT (2012) Enhanced electrochemical properties of nano-Li3PO4 coated on the LiMn2O4 cathode material for lithium ion battery at 55 °C. Mater Lett 66:168–171

Liu DQ, He ZZ, Liu XQ (2007) Increased cycling stability of AlPO4-coated LiMn2O4 for lithium ion batteries. Mater Lett 6:4703–4706

Qing C, Bai Y, Yang J, Zhang W (2011) Enhanced cycling stability of LiMn2O4 cathode by amorphous FePO4 coating. Electroch Acta 56:6612–6618

Ammugam D, Kalaignan GP (2010) Synthesis and electrochemical characterizations of nano-La2O3-coated nanostructure LiMn2O4 cathode materials for rechargeable lithium batteries. Mater Res Bull 45:1825–1831

Ha HW, Nan JK, Keon KH (2007) Improvement of electrochemical stability of LiMn2O4 by CeO2 coating for lithium-ion batteries. Electroch Acta 52:3236–3241

Padhi AK, Nanjundaswamy KS, Goodenough JB (1997) Rechargeable lithium batteries phospho-olivines as positive-electrode materials for rechargeable lithium batteries. J Electrochem Soc 144:1188–1194

Kim JK, Shin CR, Ahn JR, Matic A, Jacobsson P (2011) Highly porous LiMnPO4 in combination with an ionic liquid-based polymer gel electrolyte for lithium batteries. Electrochem Commun 13:1105–1108

Marom R, Amalraj SF, Leifer N, Jacob D, Aurbach D (2011) A review of advanced and practical lithium battery materials. J Mater Chem 21:9938–9954

Oh SM, Jung HG, Yoon CS, Myung ST, Chen ZH, Amine K, Sun YK (2011) Effect of copper doping on LiMnPO4 prepared via hydrothermal route. J Power Sources 196:6924–6928

Yamada A, Hosoya M, Chung S-C, Kudo Y, Hinokuma K, Liu K-Y, Nishi Y (2003) Olivine-type cathodes: achievements and problems. J Power Sources 119–121:232–238

Zhang Y, Zhao Y (2011) Enhanced electrochemical properties of LiMnPO4/C via Li-site substitution with Mg. Ionics 17(5):457–461

Yang G, Ni H, Liu H, Gao P, Ji H, Roy S, Pintob J, Jiang X (2011) The doping effect on the crystal structure and electrochemical properties of LiMnxM1−xPO4 (M = Mg, V, Fe, Co, Gd). J Power Sources 196:4747–4755

Hu C, Yi H, Fang H, Yang B, Yao Y, Ma W, Dai Y (2010) Improving the electrochemical activity of LiMnPO4 via Mn-site co-substitution with Fe and Mg. Electrochem Commun 12:1784–1787

Drezen T, Kwon NH, Bowen P (2007) Effect of particle size on LiMnPO4 cathodes. J Power Sources 174:949–953

Pan XL, Xu CY, Hong D, Fang HT, Zhen L (2013) Hydrothermal synthesis of well-dispersed LiMnPO4 plates for lithium ion batteries cathode. Electrochim Acta 87:303–308

Dinh HC, Mho S, Kang Y, Yeo IH (2013) Large discharge capacities at high current rates for carbon-coated LiMnPO4 nanocrystalline cathodes. J Power Sources 244:189–195

Su K, Liu F, Chen J (2013) Preparation of high performance carbon-coated LiMnPO4 nanocomposite by an acetate-assisted antisolvent precipitation method. J Power Sources 232:234–239

Liu J, Liu X, Huang T, Yu A (2013) Synthesis of nano-sized LiMnPO4 and in-situ carbon coating using a solvothermal method. J Power Sources 229:203–209

Wang D, Buqa H, Crouzet M, Deghenghi G, Drezen T, Exnar I, Kwon N-H, Miners JH, Poletto L, Grätzel M (2009) High-performance, nano-structured LiMnPO4 synthesized via a polyol method. J Power Sources 189:624–628

Acknowledgments

This project was supported by the National Science Foundation for Fostering Talents in Basic Research of China (Grant No. J1103303).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Zhang, Y. & Yuan, X. Enhanced high-temperature performances of LiMn2O4 cathode by LiMnPO4 coating. Ionics 21, 37–41 (2015). https://doi.org/10.1007/s11581-014-1169-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-014-1169-1