Abstract

Heat moisture treatment (HMT) was used to improve the functionalities of elephant foot yam starch (EFYS) by using selected heating techniques such as hot air oven (HAO), autoclave (AL), and microwave (MW). The swelling power and solubility were reduced significantly after HMT modification, whereas an increase in amylose content was detectable after HMT modification, and the maximum changes were identified in HAO-modified EFYS (28.48%) as compared to its native counterpart (18.01%). The study demonstrates that the maximum drop in peak viscosity (1045 cP) was perceived in HAO-modified EFYS, which confirms its thermostability as compared to native (1114 cP) and other treated starches (1059 to 1098 cP). All the starch pastes exhibited shear-thinning behavior, however, isothermal heating of starch paste at 95 °C revealed a rise in apparent viscosity with increasing shear rate in all HMT-modified EFYS. Large amplitude oscillatory shear (LAOS) measurements of modified starch samples showed the predominating solid-like behavior in modified EFYS. The HAO-treated EFYS had the highest elasticity of the others, which represents the enhanced structural rigidity due to the formation of transient network structures. Furthermore, Lissajous-Bowditch plots confirmed the early deviation of the structural integrity from elastic to viscous behavior in HAO-treated EFYS. Overall, the HAO-modified EFYS showed significant improvement in functionalities and structural integrities under high shear and high oscillation strain, which infers its potential industrial applications. Based on our results, we propose specific physical models suggesting the effect of molecular structural arrangements of amylose and amylopectin expressing the essential rheological differences between native and HMT EFYS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch is a major source of carbohydrates and is used as a functional ingredient in numerous food and non-food applications, including thickeners, gelling and bulking agents. The physico-chemical properties of starch lead directly to its appropriate applications. Elephant foot yam (Amorphophallus paeoniifolius) is one of the important underutilized tropical tuber crops of the Dioscoreaceae family in tropical and subtropical countries. It is rich in starch (65–70% of the wet weight) and can substitute the conventional sources of starch, including corn, potato, and rice [1, 2]. Although starch is a necessary polymeric carbohydrate that is used as a source of energy and as a raw material for food and other industrial applications, using native starch in food processing is constrained by its high thermal instability, lower mechanical strength, and lower process tolerance under higher shear forces, as well as its higher digestibility, which may have negative health effects for patients with diabetes and obesity [1,2,3]. To overcome these limitations, starch has been subjected to various kinds of modification techniques (e.g., physical, chemical, or enzymatic) to improve its quality, digestion, and applications [4]. It will be interesting to modify the starch extracted from underutilized tropical tuber crops using simple and cheap physical modification techniques to enhance the functionalities of starch.

To address the issue the current study focuses on using heat moisture treatment (HMT) for modification of starch. HMT is a hydrothermal treatment that uses an optimum moisture (≤ 35%, w/w) and temperature (80–140 °C; above the glass transition temperature and lower than the melting temperature) for a pre-determined time of 0.25 to 16 h [5]. The hot air oven is the most commonly used heating source for the HMT modification of starches [6, 7]. Many other alternative sources are available for the purpose. For example, applications of microwave (MW) and autoclave (AL) are excellent heat sources for HMT modifications. However, HMT using HAO, MW, and AL treatments has gained very little attention. HMT modification of taro and proso millet starch was reported utilizing various heating sources [6,7,8]. So far, starch isolated from elephant foot yam has not been explored for HMT using an array of techniques. Therefore, optimization of each HMT employing HAO, AL, and MW has been extensively explored for elephant foot yam starch (EFYS) to get a comprehensive understanding of the modification process, and the optimized process conditions based on digestibility minimization have been described in our earlier work [9]. The current research attempts to study the functional properties along with rheological characteristics of various hydrothermally modified EFYS under optimal conditions, which is beneficial for the design of modified starch applications in food products.

Since hydrothermal treatment of starch is a vigorous process, a significant change in the structure is expected. To study the structural stability under shearing and oscillation strain, which are common operational phenomena in food processing industries, rheological measurements can be used as an analytical technique to understand the structural organization of starch [4, 10]. Rheological measurements of starch dispersions before and after the hydrothermal treatment could provide an insight into sol–gel transformation. These changes in starch samples are mostly registered by measuring the apparent viscosity, and further compared with the pasting properties. However, steady flow at a wider shear rate breaks down the structure and does not represent the true structure of the specimen. Conversely, the structural changes can be measured precisely using the small amplitude oscillatory shear (SAOS) measurements in the linear viscoelastic region. However, in the actual industrial process, the unit operations involved in the manufacturing of food products that do not follow linearity, and most of the time the process falls in the non-linear region. These changes can be measured in the large amplitude oscillatory shear (LAOS) measurements, when the strain is minimal during oscillatory shear testing. The storage modulus (G′) and loss modulus (G′′) are independent of strain in the linear viscoelastic region (LVR), and the stress (\(\sigma\)) responds in sine function. The changes in moduli occur upon increasing the applied strain, and after a certain strain, the oscillation from the stress response gets distorted and turns into a non-sinusoidal function resulting in the absence of a linear viscoelastic region [11]. In the non-linear regime, the stress response deviates from the proportionality in its simplest forms between the deformation amplitude and stress amplitude during the LAOS condition [12]. Due to this deviation, the response of a non-sinusoidal wave is simulated using higher harmonics utilizing the Fourier transformation, which converts time-dependent responses to the frequency domain. The stress constituents diverge in the non-linear zone from linearity when the elastic (σ’) and viscous (σ”) elements of stress are displayed against strain (γ) and strain rate (γ0), respectively. A time-dependent signal that is non-sinusoidal is filtered using the Fourier transform, which turns difficult yet periodic functions into a sum of simple sine and cosine wave functions [12]. Fourier-Transform (FT) analysis and Lissajous curves are generally employed to describe the nonlinear responses determined during food processing operations [13, 14]. The coefficients of each Fourier function constitute empirical coefficients that are user-dependent and have no basic rheological meaning. Odd harmonics reflect the non-linear response of materials and express structural changes inside the material as a result of substantial deformation.

Considering the aforementioned discussion, the specific objectives of this work were the rheological characterization of hydrothermally treated EFYS dispersions by measuring the functional, rheological and mechanical properties as influenced by the source of heating at the optimized conditions. Additionally, we proposed possible biophysical schematic models which describe the effect of molecular arrangements of amylose and amylopectin during LAOS measurements.

Materials and Methods

Materials

Elephant foot yam (EFY) (cultivar: Bidhan Kusum) was obtained from Bidhan Chandra Krishi Vishwavidlaya, West Bengal, India. The chemicals and solvents used were of American Chemical Society (ACS) grade.

Starch Isolation

By using previously reported methods, starch was extracted from elephant foot yam [3, 15]. After peeling and shredding, the tubers were cleaned with tap water and dissolved in potassium metabisulphite solutions (0.25% w/v) containing 0.12% citric acid (0.12% w/v) for an hour. Grinding of tubers was done in a laboratory grinder while adding water, followed by filtration of the slurry using a 300 BSS filter mesh. The filtrate was held at 4 ºC for 90 min for sedimentation. The washing of the starch slurry was repeated several times until the pH became neutral. To ensure the maximum starch extraction, the suspension of starch was centrifuged at 3500 × g for 10 min. Decantation of the top layer was performed, and the starch was dried in a hot-air drier at 40 °C. The moisture content of the extracted starch was 6% (w/w) with 99.09% purity.

Starch Modification

Starch modification was performed at the optimized process conditions as reported in our previous study [9]. The initial moisture content of native starch was 6% (w/w). To attain the desired moisture content for each treatment, a certain amount of distilled water was added with constant stirring. The methods for preparing the optimized EFYS using various heating techniques are shown below:

-

(a)

Hot air oven treatment (HAO): EFYS (100 g, dry basis) put into screw-capped glass containers and placed in a hot air oven (Heraeus oven, Thermo Fisher Scientific, USA) at 120 ˚C with 35% moisture content (w/w) for 4 h.

-

(b)

Autoclave treatment (AL): EFYS (100 g, dry basis) put in an airtight polypropylene container and treated in an autoclave (RA-PC, Reico Equipment & Instrument, Kolkata, India) at 128 ˚C for 30 min with 15% moisture content (w/w).

-

(c)

Microwave treatment (MW): EFYS (100 g, dry basis) put in an airtight microwavable glass container and heated in a microwave oven (UWave-1000, Shanghai Sineo, China) at 520 W with 35% moisture content (w/w) for 120 s.

To acquire uniform particle sizes, all of the starch samples were ground with a mortar-pestle and passed through a 150-µm sieve.

Amylose Content

The calorimetric method was used to determine the amylose content [16]. Pure potato amylose type III (HiMedia, India) was used for the preparation of the standard curve. Starch samples (100 mg) were mixed with 1 mL of distilled ethanol and 10 mL of 1N NaOH. The mixture was kept overnight at room temperature. The volume of the solution was adjusted to 100 mL and 2.5 mL extracted solution was mixed with distilled water (20 mL) with the addition of three drops of phenolphthalein indicator. The titration was performed by adding 0.1 N HCl drop by drop until the pink color just disappears. 1 mL of iodine reagent was added to the solution and the volume was adjusted to 50 mL. Aliquots were taken from the solution to measure the absorbency at 510 nm using a spectrometer (Varian 50 Bio UV–visible spectrometer).

Functional Properties

Swelling Power and Solubility

Swelling power (SP) and solubility (SL) of native and modified EFYS were measured following the method described [17]. Starch samples (0.5 g, dry basis) was dissolved in 20 mL of distilled water and allowed for heating at 50 ºC, 60 ºC, 70 ºC, 80 ºC, and 90 ºC for 30 min in a water bath. All the heated starch pastes were centrifuged at 14000 × g for 15 min using a centrifuge (Thermo Scientific Multifuge X1R, Waltham, Massachusetts, United States). Following the centrifugation, the wet residue or sediment was weighed, and careful decantation of the supernatant was done into a pre weighed evaporating dish. Finally, the samples were allowed to dry overnight at 105 °C until a constant weight was achieved. The SP and SL were calculated using the following Eq. (1) and (2), respectively.

Water Holding Capacity (WHC)

Water holding capacity (WHC) was measured following the described method with a minor modification [18]. About 100 mg of starch samples were mixed with 10 mL distilled water in a centrifuge tube (50 mL). The starch samples were heated to 30 and 90 ºC in a water bath for 2 h, followed by cooling and centrifuged at 14,000 × g for 15 min. The supernatants were carefully discarded, and the weight of the centrifuge tubes with residue was measured. The WHC was calculated by the following Eq. (3).

Gel Permeation Chromatography (GPC)

The molar mass fraction distributions of native and modified EFYS were examined by gel permeation chromatography (GPC) using laser light scattering (SEC–MALLS) on an PSS SECcurity2 system coupled to a SLD2020/9000 laser light scattering detector (PSS Polymer Standards Service, Mainz, Germany) equipped with a He–Ne laser operating at a laser wavelength of λ0 = 660 nm and an PSS SECcurity2 RI detector. The starch samples (5 mg) were mixed with 5 mL of dimethyl sulfoxide (DMSO) with 0.5 M sodium nitrate (NaNO3) and stirred in a boiling water bath for 2 h followed by at 40 °C for 24 h before measuring. Prior to measurement the solution was filtered through a 5 μm filter. GPC experiments were performed using an Agilent Technologies 1260 instrument consisting of a pump, auto sampler and column oven. As eluent DMSO with 0.5 M NaNO3 was used. Chromatographic separation was performed by using a combination of 3 PSS GRAM columns, 10 μm, 8 × 300 mm, porosities: 30, 1000, 1000 (PSS Polymer Standards Service, Mainz, Germany) at a flow rate of 0.5 mL/min and a column temperature of 80 °C. The injection volume was 40 μL. A refractive index increment of 0.0559 mL/mg was used for evaluation (Russ, 2016). For the conventional GPC evaluation pullulane standards molar masses between 180 g/mol and 800,000 g/mol were used (PSS Polymer Standards Service Mainz, Germany). All data were recorded and evaluated by using PSS WinGPC UniChrom software (PSS Polymer Standards Service, Mainz, Germany).

Pasting Properties

The pasting properties (viscosity-temperature profile) provide the information on the gelatinization of starches with the heating temperature and time. It imitates the amylographic measurement of starch. The viscosity-temperature profile was measured in a stress-controlled rheometer (HR3 Discovery Hybrid Rheometer, TA Instruments, New Castle, England) at a constant shear rate of 200 s−1 using a stainless-steel vane geometry with a diameter of 14 mm. The native and HMT modified EFYS suspensions were prepared at 6% w/w and stirred well using a vortex shaker (Ika Vortex Genius 3, Sigma Aldrich, Germany). The well-dispersed EFYS suspension (30 mL) was transferred into the cylindrical geometry. The temperature of the test samples was increased from 25 ºC to 95 ºC with a heating rate of 5 ºC/min; holding 95 ºC for 15 min, followed by cooling to 25 ºC. A water thermo-circulator and a Peltier temperature control device were used to regulate the temperature. All the experiments were performed in triplicates, and the deviation between the runs did not exceed 5%.

Morphology of Starch Paste

The native and modified EFYS paste were prepared by heating the starch suspension (6% w/w) from 25 °C to 95 °C using a thermos shaker (Hettich Laboratory, Germany) with a heating rate of 5 °C/min. The collected starch paste was freeze dried for 3 h using freeze dryer (Alpha 1–2 LD plus, Germany). The morphology of starch paste was studied with a scanning electron microscope (LEO 1530 Gemini, Germany) using a low voltage of 0.100 kV and no sputter of metals or carbon coating was applied to the surface before the observation. The working distance of the electron probe was maintained at 1.9 mm.

Steady Shear Flow

The steady shear measurements of starch dispersions were conducted on a HR3 Discovery Hybrid rheometer (TA Instruments, New Castle, UK) using a stainless-steel parallel plate geometry (40 mm) with a gap of 1000 µm. The starch slurries (500 mg starch sample (d.b) + 2 mL distilled water) were prepared and kept for 1 h for hydration with constant stirring at 200 rpm. The starch slurries were then transferred to the lower plate fixed on a Peltier plate of the rheometer. Starch dispersions were heated isothermally at temperature above and below the gelatinization temperature at 80 ºC and 95 ºC, respectively, to understand the influence of heating on gel properties. The measurements were performed in two steps, shearing from 0.1 to 100 s−1 and 100 to 0.1 s−1 (forward and backward, respectively).

Small and Large Amplitude Oscillatory Shear Measurement

A stress-controlled HR3 Discovery Hybrid Rheometer (TA Instruments, New Castle, England) was used to test the viscoelastic characteristics of native and modified EFYS utilizing a parallel steel plate geometry (40 mm) with a geometry gap of 1000 µm. Starch samples (500 mg) were mixed with 2 mL of distilled water in a vortex shaker (Ika Vortex Genius 3, Sigma Aldrich, Germany) for 5 min to make native and modified EFYS slurries. Starch gel was prepared by heating the 25% starch suspension (dry basis) from 25 to 95 °C and again cooling down from 95 to 25 °C on the rheometer plate at a rate of 5 °C /min at a constant frequency (1 rad/s) and strain (0.5%). The silicone oil (50 mPa.s viscosity) was applied on the edge of the sample followed by placing the solvent trap on the stainless-steel geometry to minimize the evaporation loss. The starch paste samples were allowed to cool at 25 °C and equilibrated for 1 min. The small amplitude oscillatory shear (SAOS) and large amplitude oscillatory shear (LAOS) measurement were performed at 25 ºC with varied oscillation strain ranging from 0.01% to 1000% at constant angular frequency at 1 Hz. The strain sweeps were performed from 0.1 to 1000% on the test samples at a constant frequency of 1 Hz, ensuring the sample is at a fixed timescale. The raw waveforms were collected from the instrumental software (Trios, TA Instruments) and the data analyzed using the Oreo software [19].

Modelling of LAOS

The relative strength of higher harmonics is used as the nonlinear metric in Fourier-transform rheology, and the non-sinusoidal stress created by LAOS testing is expressed by the Fourier series of elastic scaling. Considering Fourier transform rheology, the entire stress response of samples can be converted from time-domain to frequency-domain by using a Fourier series of multiple harmonics, with Gn′ and Gn′′ reflecting the opposite forms of elastic and viscous scaling, respectively and described in the following Eq. (5):

Where σ is the total stress (Pa), t is the time, ω signifies angular frequency (rad/s), γ0 represents to the applied strain amplitude, Gn’ and Gn” correspond to the elastic and viscous moduli for the nth harmonic, respectively. Because the stress response is considered to be odd symmetry with respect to the directionality of strain or strain rate, this equation only includes odd harmonics5. The number of sub-harmonics in relation to the harmonic intensity is a standard method for assessing nonlinear effects.

The contribution of the nth harmonic component is quantified by the ratio In/1 (ω, γ0). However, the ratio I3/1 (ω, γ0) is considered as an index of nonlinearity. Fourier transformation was performed using Oreo software (Version 1.0) and the Lissajous-Bowditch curves were prepared using the same package [19]. Lissajous-Bowditch curves are plotted with stress versus strain at particular oscillation strain of 0.62%, 6%, 29%, 46%, 76%, 462%, and 765%.

Statistical Analysis

OriginPro 8.0 (Origin Lab Co. Northampton, MA, USA) was employed for statistical analysis. All the experiments were performed in triplicates and reported as mean ± standard deviation. Wherever applicable, means were compared by one-way analysis of variance (ANOVA) with Duncan’s multiple comparison test (p < 0.05) using SPSS statistical software (22 version, IBM) with a significance of 95%.

Results and Discussions

Amylose Content

The amylose content after HMT modification was increased in the following order of HAO > MW > AL > native EFYS and noted in Table 1. The significant difference (p < 0.05) in amylose content was observed in HAO (28.48%) and MW (26.98%) treated EFYS from native and AL treated EFYS. However, non-significant deviation in amylose content among AL treated EFYS was detected from native EFYS. HMT modification promotes the local breaking of α-(1,6)-glycosidic bond, hence leads to the increase in amylose content [4]. HAO and MW treatments were more effective in local breaking of α-(1,6)-glycosidic bonds as compared to AL treatment. The increase in amylose content after HMT modification of rice starches was also reported [6]. The local breaking of α-(1,6)-glycosidic bond was also confirmed by gel permeation chromatography (GPC) measurements which was reported in our previous publication [3]. The increase in amylose content after HMT modification plays significant role in network formation which has been described in the following physical experiments (swelling properties, pasting behavior, and large amplitude oscillatory shear study).

Functional Properties

The changes in swelling power (SP), and solubility (SL) of native and HMT EFYS as a function of temperature from 50–90 °C is addressed in Fig. 1a and b. The SP and SL of native EFYS was higher at each temperature and decreased in modified EFYS in the order of HAO < MW < AL < native EFYS. However, with increasing temperature from 50—90 °C, SP and SL were substantially increased for all samples. The increase in temperature can promote the disruption of intermolecular hydrogen bonds that allowed enhancement of water absorption. Furthermore, the highest reduction in SP was observed in HAO treated EFYS and correlated with the highest increase in amylose content. Upon increasing the temperature from 50 °C to 90 °C the higher amount of natively present amylose leaches out from granules and forms temporary transient network among themselves and with the cleaved amylopectin after local breaking of branches. This further leads to the restrictions of water uptake and swelling in HAO treated EFYS followed by MW and AL treated EFYS. The reduction in swelling properties after HMT modification also results in decreased peak viscosity which is discussed in the following section. However, our previous study reported the formation of starch particle clusters or aggregates after treatments [6]. The reduction in solubility can also be attributed to the presence of higher particle aggregates after HMT which further restricts water uptake. Both the swelling power and solubility indicates the physical interactions (strength of the hydrogen bonds) between water molecules and semi-crystalline parts of the (native) starch chains. Physically both the phenomenon compliments each other. However, from the present study it shows similar trend with the swelling power and solubility. It indicates the reduction in swelling power and solubility in modified starches as compared to native starch is due to the formation of more transient network structure upon heating. Furthermore, these results also support the water holding capacity of starches which has been discussed in the following section.

The water holding capacity (WHC) decreased significantly (p < 0.05) after HMT modification at 30 and 90 ºC in the order of HAO < MW < AL < native EFYS (Table 1). However, the increase in WHC was detected upon increasing the temperature from 30 to 90 ºC which is due to the starch gelatinization as a result of heat treatment. So, the swelling of starch associated with the gelatinization process resulted in the increase of WHC at higher temperature (90 °C). Furthermore, the decrease in WHC in HMT modified EFYS entails the formation of strong amylose-amylose and amylose-amylopectin network structure that further restricts the up taking of water molecules. The result is in accordance with the increase in amylose content and decrease in swelling properties of modified EFYS in the order of HAO < MW < AL < native EFYS. Furthermore, the reduction in WHC delayed the pasting temperature in modified EFYS which is clearly visible in the following experiments of pasting properties.

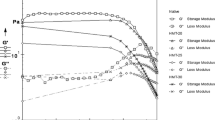

Viscosity-Temperature Profile

The non-isothermal heating of the viscosity-temperature profile of EFYS varies significantly when the starch is subjected to various HMT modification (Fig. 2). The native starch had the lowest apparent viscosity (η) and the treated starch samples showed a higher η in the order of HAO > AL > MW > native EFYS. Except for the HAO sample, which showed a gradual improvement in the η value, the starch slurries did not show any increase in η while heating the sample from 25 to 85 °C. By breaking starch crystallites, the η of native EFYS and AL EFYS dispersions began to increase at 90.6 and 92.3 °C, respectively, and continued until it reached the peak value at 95 °C. The initiation temperatures of the MW and HAO treated samples were 94.5 and 96.0 °C, respectively. Isothermal heating of starch dispersions at 95 °C for 15 min resulted in the apparent viscosity reaching a plateau. The viscosity η continued to increase when the temperature of starch dispersions decreased from 95 to 25 °C and equilibrated thereafter during holding at 25 °C. The pasting properties of the native and modified starch samples are presented in Table 2. It can be seen that the pasting temperature (PT) of the native starch (90.6 °C) was increased significantly (p < 0.05) with the treatment, and the HAO treated EFYS had the maximum value of PT (96.0 °C). The increase in PT for HMT modified EFYS can be correlated with the increase in gelatinization temperature which was reported in our previous studies [3]. It implies that HMT modified EFYS forms more stable structures and melts at a greater temperature and thus shows higher PT values (Fig. 3). The pasting parameters, namely the peak viscosity (PV), trough viscosity (TV), final viscosity (FV), breakdown viscosity (BV), and setback viscosity (SV) are reported in Table 1. The PV reduced significantly after the treatment from 1114 to 1044 cP. The decrease in PV of EFYS could be plausibly attributed to the restricted swelling ability of granules which is also confirmed from the present study. The decrease in PV occurred with the reduction in swelling properties in the following order: HAO < MS < AL < native EFYS (Fig. 1). The BV of all treated EFYS decreased significantly (p < 0.05) as compared to the native EFYS. The decrement in BD indicates an increase in the stability of starch during higher heating and shearing food processing operations [1]. Similar results were reported in HMT modified horse chestnut starch [20]. An increase in SV and FV was observed in HMT EFYS and the highest was reported in HAO modified EFYS as compared to other treatments. The increase in the FV signifies the capability of the starch to produce a viscous paste. Since the amylose in the starch paste retrogrades while cooling, the starch molecules start realigning. Upon cooling, partial recrystallization of amylopectin occurs followed by formation of amylose helical structures [21]. The presence of more amylose from local breaking of amylopectin branches in HAO and MW treatments was reported by our previous study [3]. It contributes to the presence of more amylose double helical structures and ordered crystalline phase after cooling that leads to the increase in the final viscosity during cooling in HAO and MW EFYS.

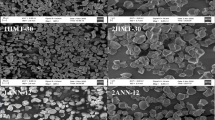

Morphology of Starch Paste

The morphology of native and modified EFYS paste observed through scanning electron microscopy is shown in Fig. 3. Native EFYS paste (Fig. 3a) revealed disruption in the granular structures with the occurrence of higher granular disorderness, surface irregularities, and the formation of dents, scratches, and pitting. However, different modification treatments have transformed the starch granules differently, which is evident from Fig. 3b-d as compared to its native counterpart. The degree of structural disorder was found to be prominent in native EFYS followed by AL-treated EFYS (Fig. 3c) and MW-treated EFYS (Fig. 3b). The changes in the morphology of the modified starch pastes was due to the different gelatinization degrees, as confirmed by the different pasting temperatures (Table 2). On the other hand, HAO EFYS paste exhibited the presence of spherical starch granules with minimal surface degradation (see red arrows in Fig. 3b). When starch suspensions are heated, the starch granules absorb water, causing structural breakdown which further leads to the increase in viscosity. As mentioned earlier, due to the lower swelling properties (Fig. 1), HAO EFYS uptakes less water causing less structural breakdown and shows lower peak viscosity. However, because of the highest increase in amylose (Table 1), HAO EFYS shows quick retrogradation upon cooling, leading to the increase in the final viscosity. Similarly, the presence of some intact granular structures in HAO EFYS confirms the less swelling capability of starch granules. Therefore, HAO EFYS paste shows higher stability as compared to its native counterpart. The development of stable structures further supports the highest increase in the pasting temperature of HAO EFYS paste.

Effect of Isothermal Heating on Steady Shear Flow Behavior

In order to understand the flow properties of gelatinized and non-gelatinized EFYS samples in their native and modified states, a steady shear flow study was conducted at two isothermal heating conditions of 80 and 95 °C signifying non-gelatinized and gelatinized conditions, respectively. Isothermal heating of both native and HMT modified starch slurries at 80 and 95 °C illustrates that the apparent viscosity (η) of all samples increased systematically as the temperature increased from 80 to 95 °C (Fig. 4). It confirms the significant increase in viscosity η for all samples after gelatinization. Furthermore, HAO and MW-treated EFYS showed the maximum increase in η, whereas AL-treated EFYS had a similar viscosity profile before and after gelatinization with native EFYS. The formation of these network structures in modified EFYS paste increases the viscosity η. One schematic model for the formation of transient network structures between natively present amylose and less branched linear part of amylopectin during gelatinization was reported earlier, which occurs due to the local breaking of amylopectin branches during modification [3]. In the order of native, AL, MW, and HAO-treated EFYS, the current study also shows a positive significant physical correlation with increases in amylose and increasing viscosity during steady shear flow. Furthermore, the highest increased viscosity was observed in HAO treated EFYS, which can be correlated with the following rheological experiment (LAOS).

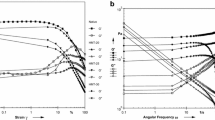

Large Amplitude Oscillatory Shear Behavior

The large amplitude oscillatory shear (LAOS) measurements were conducted with increasing the oscillation strain. Lissajous curves provide the information of visual difference in the nonlinear stress response following the distortion of the elliptical shape of the curves [22]. Consequently, in the present study the changes in viscoelastic properties of native and modified starches with the increase in applied strain amplitude was observed and reported in Fig. 5b. Native EFYS showed that at low strain amplitude the elastic Lissajous loops are ellipsoidal (up to 76% of strain), exhibiting that the response of the starch dispersions is dominated by elasticity (Fig. 5b (i)). The changes in the structural information from elastic to viscous behavior are perceived when the Lissajous-Bowditch plot shapes shift from an elliptical to a rounded parallelogram indicating a transition from elastic-dominated to viscous-dominated behavior. The information of the LAOS experiments provide further indications of the microstructure of the native and modified starch into molecular level. It also provides insight regarding the development of physical models of the native and modified starch system, reported in the present work. With increasing strain amplitudes into the nonlinear viscoelastic regime, the elastic Lissajous loops (elliptical) shift to rectangular shapes for all the samples. Native and AL treated EFYS showed elastic behavior until 76% and 46%, respectively, whereas, distortion of the elliptical shapes was noticed quite early at 29% for HAO and MW treated EFYS indicating the advanced alternation into viscous nature. In the nonlinear viscoelastic region under higher oscillation strain and following the destruction and restructuration of the starch, the linear amylose chains and branched chains of amylopectin were unraveled under shearing and transformed from random coils to an oriented state [14].

Amplitude sweep profile of native and modified EFYS (LVR: linear viscoelastic region, the black, red, blue and green dotted lines indicate the LVR region of native, HAO, AL, and MW EFYS, respectively) (a); Lissajous–Bowditch plots (y-axis is normalized stress and x-axis is normalized strain) of the system (i) native EFYS, (ii) hot air oven (HAO) treated EFYS, (iii) microwave (MW) treated EFYS, (iv) autoclave (AL) treated EFYS. Oscillation strain was denoted in the top of Lissajous–Bowditch plots (b)

The results of the experiments can be interpreted with simple physical ideas, which provide general insight into the basic processes, which might take place during heat treatment. It has been shown earlier that different heat treatment methods have an impact on the molecular composition of EFYS [3]. The molecular weight decreases and the concentration of “short chain amylose” increases. Consequently, the structure changes on the molecular level. These structural changes have impact on the shear behavior and determine the LVE as well as the shift and height of the hump in Fig. 4a. Obviously, the deformation values for the hump maximum and its height gets systematically lower with the reduction of the effective amylopectin molecular weight reproduced in Table 1. The hump if \(G{\prime}\) and \(G{\prime}{\prime}\) in starch paste preparations was previously addressed to the special structure of the gelatinized amylopectin, because the individual branched polymers cannot largely interpenetrate each other due to their large connectivity [23, 24]. Also, linear polymer chains, such as amylose are not able to penetrate branched amylose, for entropic and energetic reasons, the excluded volume interactions end up with a logarithmic repulsion by decreasing the distance [25]. However, at high shear deformations the gelatinized amylopectin is forced to come closer, the shear force needs to increase until the outer amyloses become highly deformed and the large, branched amylopectin can pass each other.

HMT of starches suggests structural changes as natively drawn in Fig. 6 in an oversimplified cartoon. Semi crystalline, branched amylopectin of native starch shows in blocklets arranged bundles consisting of double helices of amylose arms (blue and black). Native linear long chain amylose is also present as helix (red). Under sufficient presence of water, the crystalline structure melts under heat, but the molecules preserve their connectivity. Amylopectin binds most of the water, the branched molecules become highly swollen. Linear long chains amylose chains separate from the branched structures under minimizing the free energy.

During HMT some of the amylose (α-1,4) glycosylic bonds break apart (as shown exaggerated in Fig. 6), and blocklets get released from the amylopectin backbone. Depending on local water concentrations, the blocklets may rearrange to nano crystals or, alternatively, their helices unwind and contribute to the short chain amylose content under gelatinization, as also suggested by Wang for adlay starch [26]. The other consequence of random breaking of bonds creates smaller amylopectin clusters, but with similar topology as the original bundle. Some of them might resemble to a “star-like” polymer, depending on the intensity of the HMT, which is indicated indirectly by the change of the molecular weight and the corresponding increase of short chain amylose concentrations (as described in Table 1). Indeed, the structure and molecular weight of branched amylopectin remnants also decide about the stability of the nano crystals. These branched molecules show high water binding so that the local concentrations around the crystals become lower. Consequently, the nano crystals will not melt, as the melting temperature of starch crystals depends strongly on the water activity (see Vilgis (2015) for a summary) [21]. Thus, the paste of HMT starch contains a broad distribution of branched amylopectin type molecules, a blend of long and short chain amylose, and temperature resistant (reformed) blocklet crystals, as shown in Fig. 7. Dissolved linear amylose forms a concentrated polymer solution, where long chains are, in contrast to short chain amylose, able to entangle. Those form a transient polymer network aside the gelatinized branched chains. The embedded nano crystal may not find a sufficient local water concentration, remain stable, and contribute to the resistant starch fraction. The differences in the molecular structure of the starches manifests themselves in the shear experiments shown in Fig. 5a and b. Whereas linear amylose chains behave a concentrated, partly entangled polymer solution with some molecular weight distribution [27], non-interpenetrating branched chains need more attention. Especially at high shear deformations, when interacting under strong forces. The steric interaction between two nearest neighbor branched amylopectin molecules is governed by high exclusion volume interactions. The branches of different amylopectin molecules cannot entangle, even slight interpenetrations cost high energy, yielding to repulsion between the branched molecules as indicated by the red interaction zones in Fig. 8. Native starch amylopectin shows high repulsion, interpenetration is due to high branching impossible. After the HMT induced debranching, loosely parts of smaller and polydisperse molecular weight reduce the steric interactions. The polydisperse amylopectin remnants interact weaker, as shown in Fig. 8. The hump becomes less pronounced with increase of debranching due to different kinds of HMT, as can be seen clearly in Fig. 5a.

Additionally, swollen amylose in gelatinized pastes find themselves confined in a “cage”, defined by surrounding molecules, which opens only at high external shear and deformation of the outer arms of the branched molecules. Especially native amylopectin shows thus a pronounced hump in \(G{\prime}\) and \(G{\prime}{\prime}\). The debranching by HMT introduces more components and polydispersity into the system. The cage becomes less tight for the polydisperse amylopectin, the short chain amylose changes the local molecular mobility and acts as molecular lubricant between the branched polymers. In addition, debranching of chains enhances the degrees of freedom of the outer branches in the remnants. It seems that HAO treatment debranches amylopectin sufficiently that the hump consequently disappears, in contrast the other HMT. It is worthwhile to note that the shift of the hump corresponds well to the change of the molecular weight in \(G{\prime}\) and \(G{\prime}{\prime}\). The intensity of the hump systematically follows the results measured by GPC, which consistently supports the model hypothesis shown in Fig. 7 and 8.

Further confirmation is provided by the Lissajouis representation shown in Fig. 5b. The HAO-treatment shows the highest debranching leading to the significant shape change in the Lissajous-plot starts already at low deformations (29%). MW-treatment induces also a more pronounce effect, whereas AL-treatments does not seem to be most effective for debranching amylose. The details of the different shapes between the Lissajous plots come from the ratios of the concentrations of short chain amylose, long chain amylose, nano crystals etc. and need more analytics of the HMT induced components, beyond of the scope of this study.

Conclusion

In this work, we reported the fundamental physical understanding of native and HMT modified EFYS and their molecular structural influence on rheological and mechanical properties. We have shown that how HMT effects on the structural changes in amylose and amylopectin arrangements and their rheological properties and proposed physical models that explicates the impact of microstructure on flow behavior and viscoelastic properties.

HMT using different heating sources significantly influences the amylose content, swelling behavior, and water holding capacity. The highest reduction in swelling power and solubility was observed in EFYS modified with HAO treatment, which also had an impact on viscosity and rheological properties. In correspondence to this, the viscosity-temperature profile showed an increase in pasting temperature in modified EFYS, and the highest increase was reported in HAO-treated EFYS. The reduction in peak viscosity in modified EFYS can be consistent with the reduced swelling capacities. The presence of amylose in HAO-treated EFYS due to local breaking of amylopectin side chains realigned at a faster rate by forming double helical structures during cooling and thus enhanced the final viscosity. Furthermore, HMT using HAO has a profound impact on the viscosity during steady-state shear analysis, as indicated by its higher value. The viscosity of all starch samples increased significantly after gelatinization when heated isothermally at 95 °C. HAO and MW modified EFYS showed a significant increase in apparent viscosity, whereas, non-significant changes were detected in AL treated EFYS as compared to its native counterpart.

The presence of higher granular stability was observed in HAO EFYS as compared to native and other modified EFYS. The large amplitude oscillatory shear measurement shows that the structure in HAO and MW modified EFYS degrades from elastic to viscous with low oscillation strain (29%), whereas native and AL-treated EFYS exhibited elastic behavior until 76% and 46%, respectively. So, the study displays the enhanced functionality, higher granular stability, and improved viscosity of modified starch pasty in HMT EFYS modified at their optimized conditions for better applicability in the future production of modified starch-based food products.

In addition to our previous studies which focused on the lowering the digestibility of modified EFYS, this present study clearly demonstrates the improved functionalities, rheological and mechanical properties of modified EFYS which can be beneficial for obese and diabetes patients as well as food processing industries. Furthermore, looking into the developed physical models the formation of stable and embedded amylose nanocrystals in HMT modified EFYS paste contributes to the resistant starch fractions. Additionally, the differences in the molecular structure exhibits themselves in the shear experiments. However, debranching of amylopectin side chains due to HMT increases the polydispersity of the starch system which further effects the rheological properties of HMT modified EFYS. Between the branched polymers, the short chain amylose alters the local molecular mobility and functions as a lubricant and effects the mechanical properties which is clearly depicted in LAOS measurements. The ratios of the concentrations of short chain amylose, long chain amylose, nano crystals, etc. determine the specificities of the various geometries between the Lissajous plots, and further analysis of the HMT-induced components is required in future studies.

References

M. Sharma, D.N. Yadav, A.K. Singh, S.K. Tomar, Effect of heat-moisture treatment on resistant starch content as well as heat and shear stability of pearl millet starch. Agric. Res. 4, 411–419 (2015)

H. Wang, Y. Liu, L. Chen, X. Li, J. Wang, F. Xie, Insights into the multi-scale structure and digestibility of heat-moisture treated rice starch. Food Chem. 242, 323–329 (2018)

S. Barua, A. Hanewald, M. Bächle, M.M Mezger, P. Srivastav, T. Vilgis, Insights into the structural, thermal, crystalline and rheological behavior of various hydrothermally modified elephant foot yam (Amorphophallus paeoniifolius) starch. Food Hydrocoll. 129, 107672 (2022)

Q. Wang, L. Li, X. Zheng, Recent advances in heat-moisture modified cereal starch: Structure, functionality and its applications in starchy food systems. Food Chem. 344, 128700 (2021)

Z. Sui, T. Yao, Y. Zhao, X. Ye, X. Kong, L. Ai, Effects of heat–moisture treatment reaction conditions on the physicochemical and structural properties of maize starch: Moisture and length of heating. Food Chem. 173, 1125–1132 (2015)

D. Deka, N. Sit, Dual modification of taro starch by microwave and other heat moisture treatments. Int. J. Biol. Macromol. 92, 416–422 (2016)

S. Barua, P. Srivastav, Effect of heat-moisture treatment on resistant starch functional and thermal properties of mung bean (Vigna radiate) starch. J. Nutr. Health Food Eng. 7, 358–363 (2017)

M.Z. Zheng, Y. Xiao, S. Yang, H.M. Liu, M.H. Liu, S. Yaqoob, X.Y. Xu, J.S. Liu, Effects of heat–moisture, autoclaving, and microwave treatments on physicochemical properties of proso millet starch. Food Sci. Nutr. 8, 735–743 (2020)

S. Barua, M. Rakshit, P.P. Srivastav, Optimization and digestogram modeling of hydrothermally modified elephant foot yam (Amorphophallus paeoniifolius) starch using hot air oven, autoclave, and microwave treatments. LWT- Food Sci. Technol. 145, 111283 (2021)

J. Ahmed, H.S. Ramaswamy, K.C. Sashidhar, Rheological characteristics of tamarind (Tamarindus indica L.) juice concentrates. LWT - Food Sci. Technol. 40, 225–231 (2007)

Z. Liu, L. Chen, P. Bie, F. Xie, B. Zheng, An insight into the structural evolution of waxy maize starch chains during growth based on nonlinear rheology. Food Hydrocoll. 116, 106655 (2021)

O.C. Duvarci, G. Yazar, J.L. Kokini, The comparison of LAOS behavior of structured food materials (suspensions, emulsions and elastic networks). Trends Food Sci. Technol. 60, 2–11 (2017)

H.S. Melito, C.R. Daubert, E.A. Foegeding, Relating large amplitude oscillatory shear and food behavior: Correlation of nonlinear viscoelastic, rheological, sensory and oral processing behavior of whey protein isolate/κ-carrageenan gels. J. Food Process. Eng. 36, 521–534 (2013)

S. Precha-Atsawanan, D. Uttapap, L.M.C. Sagis, Linear and nonlinear rheological behavior of native and debranched waxy rice starch gels. Food Hydrocoll. 85, 1–9 (2018)

S. Sukhija, S. Singh, C.S. Riar, Effect of oxidation, cross-linking and dual modification on physicochemical, crystallinity, morphological, pasting and thermal characteristics of elephant foot yam (Amorphophallus paeoniifolius) starch. Food Hydrocoll. 55, 56–64 (2016)

S. Barua, K. Tudu, M. Rakshit, P. Srivastav, Characterization and digestogram modeling of modified elephant foot yam (Amorphophallus paeoniifolius) starch using ultrasonic pretreated autoclaving. J Food Process Eng. 44(11), 13841 (2021)

V. Marboh, C.L. Mahanta, Physicochemical and rheological properties and in vitro digestibility of heat moisture treated and annealed starch of sohphlang (Flemingia vestita) tuber. Int. J. Biol. Macromol. 168, 486–495 (2021)

J. Ahmed, H. Al-attar, Y.A. Arfat, Effect of particle size on compositional, functional, pasting and rheological properties of commercial water chestnut flour. Food Hydrocoll. 52, 888–895 (2016)

G. Luciano, S. Berretta, K.H. Liland, G.J. Donley, S.A. Rogers, Oreo: An R package for large amplitude oscillatory analysis. SoftwareX 15, 100769 (2021)

S.I. Rafiq, S. Singh, D.C. Saxena, Effect of heat-moisture and acid treatment on physicochemical, pasting, thermal and morphological properties of Horse Chestnut (Aesculus indica) starch. Food Hydrocoll. 57, 103–113 (2016)

T.A. Vilgis, Soft matter food physics—the physics of food and cooking. Rep. Prog. Phys. 78(12), 124602 (2015)

K. Tong, G. Xiao, W. Cheng, J. Chen, P. Sun, Large amplitude oscillatory shear behavior and gelation procedure of high and low acyl gellan gum in aqueous solution. Carbohydr. Polym. 199, 397–405 (2018)

N. Russ, B.I. Zielbauer, M. Ghebremedhin, T.A. Vilgis, Pre-gelatinized tapioca starch and its mixtures with xanthan gum and ι-carrageenan. Food Hydrocoll. 56, 180–188 (2016)

T.A. Vilgis, Polymeric fractals and the unique treatment of polymers. J. Phys. 49(9), 1481–1483 (1998)

T.A. Vilgis, Flory theory of polymeric fractals-intersection, saturation and condensation. Physica A 153(3), 341–354 (1988)

H. Wang, J. Ding, N. Xiao, X. Liu, Y. Zhang, H. Zhang, Insights into the hierarchical structure and digestibility of starch in heat-moisture treated adlay seeds. Food Chem. 318, 126489 (2020)

Q. Huang, O. Mednova, H.K. Rasmussen, N.J. Alvarez, A.L. Skov, K. Almdal, O. Hassager, Concentrated polymer solutions are different from melts: Role of entanglement molecular weight. Macromolecules 46(12), 5026–5035 (2013)

Acknowledgements

The authors acknowledge valuable help by Andreas Hanewald. The authors are thankful to the authorities of the Institute, German Academic Exchange Service (DAAD) for providing the services and financial assistance to conduct this study.

Funding

Open Access funding enabled and organized by Projekt DEAL. Sreejani Barua received support through the DAAD German Academic Exchange Service Research Grants—Bi-nationally Supervised Doctoral Degrees, 2019/20 (57440919).

Author information

Authors and Affiliations

Contributions

Sreejani Barua: Conceptualization, Methodology, Validation, Software, Investigation, Interpretation, Formal analysis, Data curation, Writing—original draft. Giorgio Luciano: Software, Methodology, Writing- review & editing. Jasim Ahmed: Conceptualization, Methodology, Validation, Writing- review & editing. Prem Prakash Srivastav: Supervision, Writing – review & editing. Thomas A. Vilgis: Conceptualization, Visualization, Validation, Interpretation, Modelling, Supervision, Project administration, Resources, Writing – review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Barua, S., Luciano, G., Ahmed, J. et al. Physics of Starch System: Rheological and Mechanical Properties of Hydrothermally Modified Elephant Foot Yam Starch. Food Biophysics 19, 71–84 (2024). https://doi.org/10.1007/s11483-023-09803-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-023-09803-9