Abstract

In this study, we aimed to optimize the preparation process of gelatin/wheat gliadin nanofibers and to characterize gelatin/wheat gliadin nanofibers with different weight ratios. The optimization results showed that uniform nanofibers were prepared under the following conditions: a 2:4 (v/v) 70% (v/v) ethanol and acetic acid solvent system with 22% solute concentration and 15 kV, 15 cm, and 0.75 mL/h spinning parameters. Scanning electron microscopy showed that gelatin/wheat gliadin nanofibers had good morphology, and the diameter ranged from 154.18 ± 35.65 nm to 402.38 ± 51.21 nm. Fourier transform infrared, X-ray diffraction, and circular dichroism analyses confirmed the formation of hydrogen bonds between gelatin and wheat gliadin, which increased the structural order of the nanofibers. Thermal analysis indicated that the addition of wheat gliadin had changed the thermal stability of the mixture, and the weight loss of the nanofibers ranged from 68.18% to 81.21%. The highest tensile strength (3.65 ± 0.18 MPa) and elongation at break (35.55% ± 1.78%) were found at gelatin:wheat gliadin ratios of 2:1 and 1:2, respectively. The water contact angle >90° showed that mixed films were hydrophobic. These results showed that gelatin and wheat gliadin were uniformly dispersed in the films and improved the properties of the nanofibers.

Graphical abstract

Highlights

-

Electrospinning was optimized to produce gelatin/wheat gliadin nanofibers.

-

The gelatin/gliadin fibers were more ordered than gelatin or wheat gliadin fibers.

-

The surfaces of the gelatin/wheat gliadin nanofibers were hydrophobic.

-

The mixed fibers showed more water resistant than gelatin or wheat gliadin fibers.

Similar content being viewed by others

Abbreviations

- CD:

-

Circular dichroism

- DSC:

-

Differential scanning calorimetry

- EAB:

-

Elongation at beak

- FG:WG:

-

Fish gelatin:wheat gliadin

- FTIR:

-

Fourier transform infrared

- SEM:

-

Scanning electron microscopy

- TGA:

-

Thermogravimetric analysis

- TS:

-

Tensile strength

- WCA:

-

Water contact angle

- XRD:

-

X-ray diffraction

References

H. Rostamabadi, E. Assadpour, H.S. Tabarestani, S.R. Falsafi, S.M. Jafari, Trends Food Sci. Technol. 100, 190–209 (2020)

H. Cui, C. Zhang, C. Li, L. Lin, Ind. Crop. Prod. 140, 111739 (2019)

P. Wen, M.-H. Zong, R.J. Linhardt, K. Feng, H. Wu, Trends Food Sci. Technol. 70, 56–68 (2017)

Y. Wang, Z. Guo, Y. Qian, Z. Zhang, L. Lyu, Y. Wang, F. Ye, Polymers (Basel). 11(9), 1424 (2019)

L. Deng, X. Zhang, Y. Li, F. Que, X. Kang, Y. Liu, F. Feng, H. Zhang, Food Hydrocoll. 75, 72–80 (2018)

A. Thulasisingh, S. Kannaiyan, Bull. Mater. Sci. 44(2), 119 (2021)

M. Erencia, F. Cano, J.A. Tornero, M.M. Fernandes, T. Tzanov, J. Macanás, F. Carrilo, J. Appl. Polym. Sci. 132, 25 (2015)

S. Sahraee, J.M. Milani, B. Ghanbarzadeh, H. Hamishehkar, Int. J. Biol. Macromol. 97, 373–381 (2017)

C. Zhou, M.A. Abdel-Samie, C. Li, H. Cui, L. Lin, Food Packag shelf. Life. 26, 100586 (2020)

D. Wang, J. Sun, J. Li, Z. Sun, F. Liu, L. Du, D. Wang, Food Chem. 373, 131439 (2022)

Y. Wang, L. Chen, Macromol. Mater. Eng. 297(9), 902–913 (2012)

L. Deng, Y. Li, F. Feng, H. Zhang, Food Hydrocoll. 87, 1–10 (2019)

S. Voci, M. Fresta, D. Cosco, J. Control. Release 329, 385–400 (2021)

W. Wu, X. Kong, C. Zhang, Y. Hua, Y. Chen, Food Hydrocoll. 80, 78–87 (2018)

T. Chen, Z. Song, H. Liu, C. Zhou, P. Hong, C. Deng, Food Biosci. 47, 101650 (2022)

Z. Song, H. Liu, L. Chen, L. Chen, C. Zhou, P. Hong, C. Deng, Food Chem. 340, 128139 (2021)

Y. Zhu, X. Chen, D.J. McClements, L. Zou, W. Liu, Food Hydrocoll. 77, 870–878 (2018)

X. Guan, L. Li, S. Li, J. Liu, K. Huang, Food Biosci. 37, 100687 (2020)

L. Li, H. Wang, M. Chen, S. Jiang, J. Cheng, X. Li, M. Zhang, S. Jiang, Food Hydrocoll. 101, 105577 (2020)

M. Karim, M. Fathi, S. Soleimanian-Zad, Food Bioprod. Process. 122, 193–204 (2020)

K. An, H. Liu, S. Guo, D.N.T. Kumar, Q. Wang, Int. J. Biol. Macromol. 47(3), 380–388 (2010)

B.N. Singh, N.N. Panda, K. Pramanik, Int. J. Biol. Macromol. 87, 201–207 (2016)

B. Ghorani, N. Tucker, Food Hydrocoll. 51, 227–240 (2015)

P.K. Akman, F. Bozkurt, M. Balubaid, M.T. Yilmaz, Fiber Polym. 20(6), 1187–1199 (2019)

H.W. Kwak, M. Shin, J.Y. Lee, H. Yun, D.W. Song, Y. Yang, B.-S. Shin, Y.H. Park, K.H. Lee, Int. J. Biol. Macromol. 102, 1092–1103 (2017)

N. Okutan, P. Terzi, F. Altay, Food Hydrocoll. 39, 19–26 (2014)

T.M. Righi, R.S. Almeida, M.A. d'Ávila, Macromol. Symp. 319(1), 230–234 (2012)

Z. Sun, M. Li, Z. Jin, Y. Gong, Q. An, X. Tuo, J. Guo, Int. J. Biol. Macromol. 120, 2552–2559 (2018)

N. Amiri, Z. Rozdeh, T. Afrough, S.A.S. Tavassi, A. Moradi, J. Movaffagh, BioNanoScience. 8, 778–789 (2018)

A. Jabur, International Conference of Physics Scince. (2014). https://doi.org/10.13140/RG.2.2.14714.90569

M.-M. Mousavi, M. Torbati, P. Farshi, H. Hosseini, M.A. Mohammadi, S.M. Hosseini, S. Hosseinzadeh, Adv Pharm Bull. 11(3), 514–521 (2021)

S. Chen, Y. Ma, L. Dai, W. Liao, L. Zhang, J. Liu, Y. Gao, Food Hydrocoll. 118, 106758 (2021)

L.C. Sow, N.Z.Y. Toh, C.W. Wong, H. Yang, Food Hydrocoll. 94, 459–467 (2019)

L.C. Sow, S.J. Tan, H. Yang, Food Hydrocoll. 90, 9–18 (2019)

L.C. Sow, H. Yang, Food Hydrocoll. 45, 72–82 (2015)

M. Li, H. Yu, Y. Xie, Y. Guo, Y. Cheng, H. Qian, W. Yao, LWT - Food Sci Technol. 139, 110800 (2021)

L. Deng, X. Kang, Y. Liu, F. Feng, H. Zhang, Food Hydrocoll. 74, 324–332 (2018)

F. Liu, Y. Liu, Z. Sun, D. Wang, H. Wu, L. Du, D. Wang, Int. J. Biol. Macromol. 164, 3376–3387 (2020)

B. Vafania, M. Fathi, S. Soleimanian-Zad, Food Bioprod. Process. 116, 240–248 (2019)

E. Tavassoli-Kafrani, S.A.H. Goli, M. Fathi, Int. J. Biol. Macromol. 103, 1062–1068 (2017)

Z. Song, H. Liu, A. Huang, C. Zhou, P. Hong, C. Deng, J. Food Eng. 317, 110860 (2022)

Y. Liu, D. Wang, Z. Sun, F. Liu, L. Du, D. Wang, Int. J. Biol. Macromol. 169, 161–170 (2021)

B. Ghorani, B. Emadzadeh, H. Rezaeinia, S.J. Russell, Food Hydrocoll. 104, 105740 (2020)

Y. Zhang, L. Deng, H. Zhong, Y. Zou, Z. Qin, Y. Li, H. Zhang, Food Chem. 366, 130586 (2022)

C.S. Ki, D.H. Baek, K.D. Gang, K.H. Lee, I.C. Um, Y.H. Park, Polymer. 46(14), 5094–5102 (2005)

L. Li, H. Wang, M. Chen, S. Jiang, S. Jiang, X. Li, Q. Wang, Food Chem. 269, 142–149 (2018)

Y.P. Neo, S. Ray, J. Jin, M. Gizdavic-Nikolaidis, M.K. Nieuwoudt, D. Liu, S.Y. Quek, Food Chem. 136(2), 1013–1021 (2013)

H. Homayoni, S.A.H. Ravandi, M. Valizadeh, Carbohydr. Polym. 77(3), 656–661 (2009)

Y. Li, C. Tang, Q. He, Food Biosci. 41, 100927 (2021)

Acknowledgements

The authors are grateful to the Editage (www.editage.cn) for English language editing.

Funding

This work was supported by the Southern Marine Science and Engineering Laboratory (Zhanjiang) (ZJW-2019-07); the Innovation and Development Project about Marine Economy Demonstration of Zhanjiang City (2017C8B1); the Innovation Team Construction Project of Modern Agricultural Industry Technology System in Guangdong Province (2021KJ150); the Science and Technology plan project of Zhanjiang City (2019A03021); and the Innovative Team Program of High Education of Guangdong Province (2021KCXTD021).

Author information

Authors and Affiliations

Contributions

Tingju Chen: Investigation, Methodology, Writing-Original draft preparation. Huanming Liu: Conceptualization, Methodology, Writing-Reviewing, Editing. Chujin Deng: Reviewing, Editing, and Resources. Chunxia Zhou: Reviewing and Editing. Pengzhi Hong: Funding acquisition, Supervision.

Corresponding author

Ethics declarations

Conflict of Interest

There are no conflicts of interest to report.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Fig. S1

Scanning electron microscopy (SEM) images and diameter trend of the gelatin/wheat gliadin nanofibers at various voltages (a) 12 kV, (b) 15 kV, (c) 18 kV, (d) 21 kV, (e) 24 kV, (f) diameter trend. Parameters: 2:4 (v/v) 70% (v/v) ethanol and acetic acid, 22% (w/v) solute concentrations (gelatin:wheat gliadin 1:1, w/w), 15 cm receiving distance, and 0.5 mL/h injection rate. (PNG 2161 kb)

Fig. S2

Scanning electron microscopy (SEM) images and diameter trend of the gelatin/wheat gliadin nanofibers at various receiving distances (a) 11 cm, (b) 13 cm, (c) 15 cm, (d) 17 cm, (e) 19 cm, (f) diameter trend. Parameters: 2:4 (v/v) 70% (v/v) ethanol and acetic acid, 22% (w/v) solute concentrations (gelatin:wheat gliadin 1:1, w/w), 15 kV voltage, and 0.5 mL/h injection rate. (PNG 2164 kb)

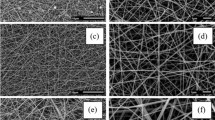

Fig. S3

Scanning electron microscopy (SEM) images and diameter trend of the gelatin/wheat gliadin nanofibers at various injection rates (a) 0.25 mL/h, (b) 0.5 mL/h, (c) 0.75 mL/h, (d) 1.0 mL/h, (e) 1.25 mL/h, (f) diameter trend. Parameters: 2:4 (v/v) 70% (v/v) ethanol and acetic acid, 22% (w/v) solute concentrations (gelatin:wheat gliadin 1:1, w/w), 15 kV voltage, and 15 cm receiving distance. (PNG 2180 kb)

Rights and permissions

About this article

Cite this article

Chen, T., Liu, H., Deng, C. et al. Optimization and Characterization of the Gelatin/Wheat Gliadin Nanofiber Electrospinning Process. Food Biophysics 17, 621–634 (2022). https://doi.org/10.1007/s11483-022-09748-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-022-09748-5