Abstract

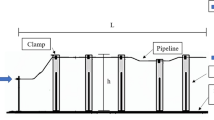

In the design and troubleshooting of aero-engine pipeline, the vibration reduction of the pipeline system is often achieved by adjusting the hoop layout, provided that the shape of pipeline remains unchanged. However, in reality, the pipeline system with the best antivibration performance may be obtained only by adjusting the pipeline shape. In this paper, a typical spatial pipeline is taken as the research object, the length of straight-line segment is taken as the design variable, and an innovative optimization method of avoiding vibration of aero-engine pipeline is proposed. The relationship between straight-line segment length and parameters that determine the geometric characteristics of the pipeline, such as the position of key reference points, bending angle, and hoop position, are derived in detail. Based on this, the parametric finite element model of the pipeline system is established. Taking the maximum first-order natural frequency of pipeline as the optimization objective and introducing process constraints and vibration avoidance constraints, the optimization model of the pipeline system is established. The genetic algorithm and the golden section algorithm are selected to solve the optimization model, and the relevant solution procedure is described in detail. Finally, two kinds of pipelines with different total lengths are selected to carry out a case study. Based on the analysis of the influence of straight-line segment length on the vibration characteristics of the pipeline system, the optimization methods developed in this paper are demonstrated. Results show that the developed optimization method can obtain the optimal single value or interval of the straight-line segment length while avoiding the excitation frequency. In addition, the optimization efficiency of the golden section algorithm is remarkably higher than that of the genetic algorithm for length optimization of a single straight-line segment.

Similar content being viewed by others

References

Tian J L, Yuan C F, Yang L, Wu C M, Liu G, Yang Z. The vibration characteristics analysis of pipeline under the action of gas pressure pulsation coupling. Journal of Failure Analysis and Prevention, 2016, 16(3): 499–505

Guo X M, Ma H, Zhang X F, Ye Z, Fu Q, Liu Z H, Han Q K. Uncertain frequency responses of clamp-pipeline systems using an interval-based method. IEEE Access: Practical Innovations, Open Solutions, 2020, 8: 29370–29384

Qu Y F, Jiang D, Yang Q Y. Branch pipe routing based on 3D connection graph and concurrent ant colony optimization algorithm. Journal of Intelligent Manufacturing, 2018, 29(7): 1647–1657

Liu Q, Wang C G. Pipe-assembly approach for aero-engines by modified particle swarm optimization. Assembly Automation, 2010, 30(4): 365–377

Ren T, Zhu Z L, Dimirovski G M, Gao Z H, Sun X H, Yu H. A new pipe routing method for aero-engines based on genetic algorithm. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2014, 228(3): 424–434

Van der Velden C, Bil C, Yu X H, Smith A. An intelligent system for automatic layout routing in aerospace design. Innovations in Systems and Software Engineering, 2007, 3(2): 117–128

Wang C G, Liu Q. Projection and geodesic-based pipe routing algorithm. IEEE Transactions on Automation Science and Engineering, 2011, 8(3): 641–645

Liu X D, Sun W, Gao Y, Ma H. Optimization of pipeline system with multi-hoop supports for avoiding vibration, based on particle swarm algorithm. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2021, 235(9): 1524–1538

Liu X D, Sun W, Gao Z H. Optimization of hoop layouts for reducing vibration amplitude of pipeline system using the semi-analytical model and genetic algorithm. IEEE Access: Practical Innovations, Open Solutions, 2020, 8: 224394–224408

Zhang Z, Zhou C C, Wang W X, Yue Z F. Optimization design of aeronautical hydraulic pipeline system based on non-probabilistic sensitivity analysis. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 2019, 233(5): 815–825

Tang Z C, Lu Z Z, Li D W, Zhang F. Optimal design of the positions of the hoops for a hydraulic pipelines system. Nuclear Engineering and Design, 2011, 241(12): 4840–4855

Wang W X, Zhou C C, Gao H S, Zhang Z. Application of non-probabilistic sensitivity analysis in the optimization of aeronautical hydraulic pipelines. Structural and Multidisciplinary Optimization, 2018, 57(6): 2177–2191

Kwong A H M, Edge K A. A method to reduce noise in hydraulic systems by optimizing pipe clamp locations. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 1998, 212(4): 267–280

Zhang X T, Liu W, Zhang Y M, Zhao Y J. Experimental investigation and optimization design of multi-support pipeline system. Chinese Journal of Mechanical Engineering, 2021, 34(1): 10

Gao P X, Li J W, Zhai J Y, Tao Y, Han Q K. A novel optimization layout method for clamps in a pipeline system. Applied Sciences (Basel, Switzerland), 2020, 10(1): 390

Zhang X T, Liu W. The effect of pipeline layout parameters on mode and dynamic stress of “airframe-clamps-pipeline” structure. Multidiscipline Modeling in Materials and Structures, 2020, 16(2): 373–389

Chen L M, Liu K X, Yao Y F, Yao J, Su Z X, Luo G F. Flow analysis in right-angled pipes with different geometric shapes and parameters for sludge discharge in slime shield machines measured using a CFD-DEM method. International Journal for Computational Methods in Engineering Science and Mechanics, 2020, 21(5): 231–242

Nivelle P, Tsanakas J A, Poortmans J, Daenen M. Stress and strain within photovoltaic modules using the finite element method: a critical review. Renewable and Sustainable Energy Reviews, 2021, 145: 111022

Gravenkamp H, Saputra A A, Duczek S. High-order shape functions in the scaled boundary finite element method revisited. Archives of Computational Methods in Engineering, 2021, 28(2): 473–494

Gao P X, Zhai J Y, Qu F Z, Han Q K. Vibration and damping analysis of aerospace pipeline conveying fluid with constrained layer damping treatment. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2018, 232(8): 1529–1541

Gao P X, Zhai J Y, Yan Y Y, Han Q K, Qu F Z, Chen X H. A model reduction approach for the vibration analysis of hydraulic pipeline system in aircraft. Aerospace Science and Technology, 2016, 49: 144–153

Gao P X, Zhang Y L, Liu X F, Yu T, Wang J. Vibration analysis of aero parallel-pipeline systems based on a novel reduced order modeling method. Journal of Mechanical Science and Technology, 2020, 34(8): 3137–3146

Xu P Y, Liu W. Multi-objective optimization of clamps layout for engine external pipeline system. Aeroengine, 2020, 46(6): 46–52 (in Chinese)

Chai Q D, Zeng J, Ma H, Li K, Han Q K. A dynamic modeling approach for nonlinear vibration analysis of the L-type pipeline system with clamps. Chinese Journal of Aeronautics, 2020, 33(12): 3253–3265

Sui H T, Niu W T. Branch-pipe-routing approach for ships using improved genetic algorithm. Frontiers of Mechanical Engineering, 2016, 11(3): 316–323

Dhingra S, Bhushan G, Dubey K K. Multi-objective optimization of combustion, performance and emission parameters in a jatropha biodiesel engine using non-dominated sorting genetic algorithm-II. Frontiers of Mechanical Engineering, 2014, 9(1): 81–94

Adanza Dopazo D, Moreno Pelayo V, Génova Fuster G. An automatic methodology for the quality enhancement of requirements using genetic algorithms. Information and Software Technology, 2021, 140(1): 106696

Huynh T T B, Pham D T, Tran B T, Le C T, Le M H P, Swami A, Bui T L. A multifactorial optimization paradigm for linkage tree genetic algorithm. Information Sciences, 2020, 540: 325–344

Nataraj P S V, Sondur S. The extrapolated interval global optimization algorithm. Journal of Global Optimization, 2011, 50(2): 249–270

Dolgov Y G. Developing interval global optimization algorithms on the basis of branch-and-bound and constraint propagation methods. Reliable Computing, 2005, 11(5): 343–358

Chenouard R, El-Sehiemy R A. An interval branch and bound global optimization algorithm for parameter estimation of three photovoltaic models. Energy Conversion and Management, 2020, 205: 112400

Acknowledgements

This work was supported by the Major Projects of Aero-Engines and Gas Turbines (J2019-I-0008-0008) and the Fundamental Research Funds for the Central Universities of China (Grant No. N180312012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, W., Sun, W., Wang, D. et al. Optimization of aero-engine pipeline for avoiding vibration based on length adjustment of straight-line segment. Front. Mech. Eng. 17, 11 (2022). https://doi.org/10.1007/s11465-021-0667-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11465-021-0667-x