Abstract

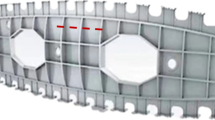

Billet optimization can greatly improve the forming quality of the transitional region in the isothermal local loading forming (ILLF) of large-scale Ti-alloy rib-web components. However, the final quality of the transitional region may be deteriorated by uncontrollable factors, such as the manufacturing tolerance of the preforming billet, fluctuation of the stroke length, and friction factor. Thus, a dual-response surface method (RSM)-based robust optimization of the billet was proposed to address the uncontrollable factors in transitional region of the ILLF. Given that the die underfilling and folding defect are two key factors that influence the forming quality of the transitional region, minimizing the mean and standard deviation of the die underfilling rate and avoiding folding defect were defined as the objective function and constraint condition in robust optimization. Then, the cross array design was constructed, a dual-RSM model was established for the mean and standard deviation of the die underfilling rate by considering the size parameters of the billet and uncontrollable factors. Subsequently, an optimum solution was derived to achieve the robust optimization of the billet. A case study on robust optimization was conducted. Good results were attained for improving the die filling and avoiding folding defect, suggesting that the robust optimization of the billet in the transitional region of the ILLF was efficient and reliable.

Similar content being viewed by others

References

Yang H, Fan X G, Sun Z C, et al. Recent developments in plastic forming technology of titanium alloys. Science China. Technological Sciences, 2011, 54(2): 490–501

Kleiner M, Geiger M, Klaus A. Manufacturing of lightweight components by metal forming. CIRP Annals-Manufacturing Technology, 2003, 52(2): 521–542

Fan X G, Yang H, Gao P F. Through-process macro-micro finite element modeling of local loading forming of large-scale complex titanium alloy component for microstructure prediction. Journal of Materials Processing Technology, 2014, 214(2): 253–266

Yang H, Gao P F, Fan X G, et al. Some advances in plastic forming technologies of titanium alloys. Procedia Engineering, 2014, 81: 44–53

Yang H, Fan X G, Sun Z C, et al. Some advances in local loading precision forming of large scale integral complex components of titanium alloys. Materials Research Innovations, 2011, 15(Supp1 s1): s493–s496

Sun Z C, Yang H, Sun N G. Effects of parameters on inhomogeneous deformation and damage in isothermal local loading forming of Ti-alloy component. Journal of Materials Engineering and Performance, 2012, 21(3): 313–323

Gao P F, Yang H, Fan X G, et al. Quick prediction of the folding defect in transitional region during isothermal local loading forming of titanium alloy large-scale rib-web component based on folding index. Journal of Materials Processing Technology, 2015, 219: 101–111

Gao P F, Yang H, Fan X G, et al. Forming defects control in transitional region during isothermal local loading of Ti-alloy ribweb component. International Journal of Advanced Manufacturing Technology, 2015, 76(5–8): 857–868

Wei K, Zhan M, Fan X G, et al. Unequal-thickness billet optimization in transitional region during isothermal local loading forming of Ti-alloy rib-web component using response surface method. Chinese Journal of Aeronautics, 2017. https://doi.org/ 10.1016/j.cja.2017.07.005

Gao P F, Li X D, Yang H, et al. Improving the process forming limit considering forming defects in the transitional region in local loading forming of Ti-alloy rib-web components. Chinese Journal of Aeronautics, 2017, 30(3): 1270–1280

Taguchi G. Taguchi on Robust Technology Development: Bringing Quality Engineering Upstream. New York: ASME Press, 1993

Hou B, Wang W R, Li S H, et al. Stochastic analysis and robust optimization for a deck lid inner panel stamping. Materials & Design, 2010, 31(3): 1191–1199

Huang Z L, Wang G, Wei S P, et al. Process improvement in laser hot wire cladding for martensitic stainless steel based on the Taguchi method. Frontiers of Mechanical Engineering, 2016, 11(3): 242–249

Li H, Xu J, Yang H, et al. Sequential multi-objective optimization of thin-walled aluminum alloy tube bending under various uncertainties. Transactions of Nonferrous Metals Society of China, 2017, 27 (3): 608–615

Li Y Q. Research on six sigma robust optimization of sheet metal forming. Dissertation for the Doctoral Degree. Shanghai: Shanghai Jiaotong University, 2006 (in Chinese)

Wei K, Yang H, Fan X G, et al. Unequal thickness billet design for large-scale titanium alloy rib-web components under isothermal closed-die forging. International Journal of Advanced Manufacturing Technology, 2015, 81(5–8): 729–744

Zhang D W, Yang H. Metal flow characteristics of local loading forming process for rib-web component with unequal-thickness billet. International Journal of Advanced Manufacturing Technology, 2013, 68(9–12): 1945–1965

Huang T L, Song X W, Liu X Y. The multi-objective robust optimization of the loading path in the T-shape tube hydroforming based on dual response surface model. International Journal of Advanced Manufacturing Technology, 2016, 82(9–12): 1595–1605

Shen C W. Research on material constitution models of TA15 and TC11 titanium alloys in hot deformation process. Thesis for the Master’s Degree. Xi’an: Xi’an Northwestern Polytechnical University, 2007 (in Chinese)

Acknowledgments

The authors would like to gratefully acknowledge the support given by the National Natural Science Foundation of China (Grant No. 51575449), Research Fund of the State Key Laboratory of Solidification Processing (NWPU), China (Grant No. 104-QP-2014), 111 Project (Grant No. B08040), and Fundamental Research Funds for the Central Universities (Grant No. 3102015AX004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, K., Fan, X., Zhan, M. et al. Robust optimization of the billet for isothermal local loading transitional region of a Ti-alloy rib-web component based on dual-response surface method. Front. Mech. Eng. 13, 376–384 (2018). https://doi.org/10.1007/s11465-018-0500-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-018-0500-3