Abstract

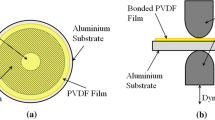

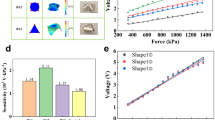

Packaged piezoelectric ceramic actuators (PPCAs) and compliant mechanisms are attractive for nanopositioning and nanomanipulation due to their ultra-high precision. The way to create and keep a proper and steady connection between both ends of the PPCA and the compliant mechanism is an essential step to achieve such a high accuracy. The connection status affects the initial position of the terminal moving plate, the positioning accuracy and the dynamic performance of the nanopositioning platform, especially during a long-time or high-frequency positioning procedure. This paper presents a novel external preload mechanism and tests it in a 1-degree of freedom (1-DOF) compliant nanopositioning platform. The 1-DOF platform utilizes a parallelogram guiding mechanism and a parallelogram load mechanism to provide a more accurate actual input displacement and output displacement. The simulation results verify the proposed stiffness model and dynamic model of the platform. The values of the preload displacement, actual input displacement and output displacement can be measured by three capacitive sensors during the whole positioning procedure. The test results show the preload characteristics vary with different types or control modes of the PPCA. Some fitting formulas are derived to describe the preload displacement, actual input displacement and output displacement using the nominal elongation signal of the PPCA. With the identification of the preload characteristics, the actual and comprehensive output characteristics of the PPCA can be obtained by the strain gauge sensor (SGS) embedded in the PPCA.

Similar content being viewed by others

References

Zhang Y L, Zhang Y, Ru C, et al. A load-lock-compatible nanomanipulation system for scanning electron microscope. IEEE/ASME Transactions on Mechatronics, 2013, 18(1): 230–237

Tang H, Li Y. Design, analysis, and test of a novel 2-DOF nanopositioning system driven by dual mode. IEEE Transactions on Robotics, 2013, 29(3): 650–620

Yong Y K, Moheimani S O R, Kenton B J, et al. Invited review article: High-speed flexure-guided nanopositioning: Mechanical design and control issues. Review of Scientific Instruments, 2012, 83(12): 121101–121122

Espinosa H D, Zhu Y, Moldovan N. Design and operation of a mems-based material testing system for nanomechanical characterization. Journal of Microelectromechanical Systems, 2007, 16(5): 1219–1231

Fukuda T, Nakajima M, Liu P, et al. Nanofabrication, nanoinstrumentation and nanoassembly by nanorobotic manipulation. International Journal of Robotics Research, 2009, 28(4): 537–547

Wang H, Zhang X. Input coupling analysis and optimal design of a 3-DOF compliant micro-positioning stage. Mechanism and Machine Theory, 2008, 43(4): 400–410

Kim H, Gweon D G. Development of a compact and long range xyθz nanopositioningstage. Review of Scientific Instruments, 2012, 83(8): 085102–085108

Culpepper M L, Anderson G. Design of a low-cost nano-manipulator which utilizes a monolithic, spatial compliant mechanism. Precision Engineering, 2004, 28(4): 469–482

Li Y, Xu Q. A totally decoupled piezo-driven XYZ flexure parallel micropositioning stage for micro/nanomanipulation. IEEE Transactions on Automation Science and Engineering, 2011, 8(2): 265–279

Wang R, Zhang X. Design & test of a novel planar 3-DOF precision positioning platform with a large magnification. In: Proceedings of 2014 International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO). Taipei: IEEE, 2014, 288–295

Howell L L. Compliant Mechanisms. New York: Wiley-Inter-Science, 2001

Lobontiu N. Compliant Mechanisms: Design of Flexure Hinges. Boca Raton: CRC Press, 2003

Yong Y K, Lu T F, Handley D C. Review of circular flexure hinge design equations and derivation of empirical formulations. Precision Engineering, 2008, 32(2): 63–70

Lin R, Zhang X, Long X, et al. Hybrid flexure hinges. Review of Scientific Instruments, 2013, 84(8): 085004–085014

Adriaens H J M T S, de Koning W, Banning R. Modeling piezoelectric actuators. IEEE/ASME Transactions on Mechatronics, 2000, 5(4): 331–341

Ge P, Jouaneh M. Tracking control of a piezoceramic actuator. IEEE Transactions on Control Systems Technology, 1996, 4(3): 209–216

Baxter L K. Capacitive Sensors: Design and Applications. Piscataway: IEEE Press, 1997

Fleming A J. A review of nanometer resolution position sensors: Operation and performance. Sensors and Actuators A: Physical, 2013, 190: 106–126

Tian Y, Shirinzadeh B, Zhang D. Design and dynamics of a 3-DOF flexure-based parallel mechanism for micro/nano manipulation. Microelectronic Engineering, 2010, 87(2): 230–241

Yong Y K, Aphale S S, Moheimani S O R. Design, identification, and control of a flexure-based XY stage for fast nanoscale positioning. IEEE Transactions on Nanotechnology, 2009, 8(1): 46–54

Leang K K, Fleming A J. High-speed serial-kinematic SPM scanner: Design and drive considerations. Asian Journal of Control, 2009, 11(2): 144–153

Zhang X, Wang R. China Patent, 2014103010471, 2014-06-27

Bathe K J, Wilson E L. Numerical Methods in Finite Element Analysis. Englewood Cliffs: Prentice-Hall, 1976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, R., Zhang, X. Preload characteristics identification of the piezoelectric-actuated 1-DOF compliant nanopositioning platform. Front. Mech. Eng. 10, 20–36 (2015). https://doi.org/10.1007/s11465-015-0328-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-015-0328-z