Abstract

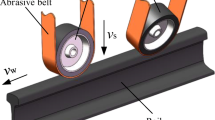

Rails endure frequent dynamic loads from the passing trains for supporting trains and guiding wheels. The accumulated stress concentrations will cause the plastic deformation of rail towards generating corrugations, contact fatigue cracks and also other defects, resulting in more dangerous status even the derailment risks. So the rail grinding technology has been invented with rotating grinding stones pressed on the rail with defects removal. Such rail grinding works are directed by experiences rather than scientifically guidance, lacking of flexible and scientific operating methods. With grinding control unit holding the grinding stones, the rail grinding process has the characteristics not only the surface grinding but also the running railway vehicles. First of all, it’s important to analyze the contact length between the grinding stone and the rail, because the contact length is a critical parameter to measure the grinding capabilities of stones. Moreover, it’s needed to build up models of railway vehicle unit bonded with the grinding stone to represent the rail grinding car. Therefore the theoretical model for contact length is developed based on the geometrical analysis. And the calculating models are improved considering the grinding car’s dynamic behaviors during the grinding process. Eventually, results are obtained based on the models by taking both the operation parameters and the structure parameters into the calculation, which are suitable for revealing the process of rail grinding by combining the grinding mechanism and the railway vehicle systems.

Similar content being viewed by others

References

Grassie S L. Rail corrugation: advances in measurement, understanding and treatment. Wear Contact Mechanics and Wear of Rail/Wheel Systems. 2005, 258(7–8): 1224–1234

Schoech W. Rolling contact fatigue mitigation by grinding. In: Proceedings of the Rail Tech Europe Conference, Utrecht, 2007

Kanematsu Y, Satoh Y. Influence of Type of Grinding Stone on Rail Grinding Efficiency. Quarterly Report of RTRI. 2011, 52(2): 97–102

Zarembski A M, Palese J. Does rail grinding reduce rail defects? Rail Track & Structures, 2011, 2: 32–35

Schoech W, Heyder R, Grohmann D. Contact geometry and surface fatigue guidelines for appropriate rail maintenance. In: 7th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems. Brisbane, 2006

Zarembski M, Patel P. Estimating maintenance costs for mixed higher speed passenger and freight rail corridors. In: Proceedings of the 2010 Joint Rail Conference. Urbana, 2010

Cheng C C, Kuo F C, Wang C P, Cheng W N. Vibration analysis of rail grinding using a twin-wheel grinder. Journal of Sound and Vibration, 2011, 330(7): 1382–1392

Hempe T, Siefer T. Rail grinding as an integral part of technically and economically efficient track maintenance. Rail Engineering International, 2007, 36(3): 6–12

Schoech W. Managing rail life to match performance and cut costs. Railway Gazette International, 2010, 8: 45–48

Schoech W. Development of rail grinding strategies in Europe. In: Conference on Railway Engineering. Rail Achieving Growth: Conference Proceeding. Melbourne, 2006, 95–100

Marcel T. High speed grinding preventative rail care. In: 7th World Congress on High Speed Rail. Beijing, 2010

Scroba P, Roney M. Rail grinding best practices. In: Proceedings of AREMA Annual Conference. Chicago, 2003

Hyde P, Fletcher D. Planning rail grinding using crack growth predictions. Journal of Mechanical Systems for Transportation and Logistics, 2010, 3(1): 216–225

Rowe WB. Principles of Modern Grinding Technology. Burlington: Science Publishers, 2009

Grassie S L, Gregory R W, Harrison D, Johnson K L. The dynamic response of railway track to high frequency vertical exitation. Journal of Mechanical Engineering Science, 1982, 24(2): 77–90

Grassie S L, Cox S J. The dynamic response of railway track with flexible sleepers to high frequency vertical excitation. In: Proceedings of the Institution of Mechanical Engineers, Part D: Transport Engineering, 1984, 117–124

Calogero F, Leyvraz F. On a new technique to manufacturing isochronous Hamiltonian systems: classical and quantal treatments. Journal of Nonlinear Mathematical Physics, 2007, 14(4): 612–636

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhi, S., Li, J. & Zarembski, A.M. Modelling of dynamic contact length in rail grinding process. Front. Mech. Eng. 9, 242–248 (2014). https://doi.org/10.1007/s11465-014-0305-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-014-0305-y