Abstract

It is helpful to study the creep process of rock by modeling the process of damage evolution in triaxial creep test. Based on the statistical distribution of strength of representative element, a dynamic damage model suitable for the initial loading stage is established. From the perspective of strength deterioration of representative element, the similarity of damage characteristics between characteristic representative element and rock sample during creep is found, and a time-dependent damage model suitable for the constant loading stage is also obtained. And the quantitative identification of parameters in the damage model is realized based on the cumulative acoustic emission (AE) count, which reveals the whole process of damage evolution in triaxial creep test. In addition, the power-law dashpot suitable for the accelerated creep stage is proposed, and the fractional non-Newtonian creep model considering the damage evolution is further established. The parameters of creep model are also identified by the stepwise least square fitting (LSF), and the applicability and superiority of the models are verified.

Similar content being viewed by others

Data availability

All data, models and codes generated or used during the study appear in the published article.

Abbreviations

- K :

-

Strength of representative element (MPa)

- f(k):

-

Probability density function of strength

- m :

-

Shape parameter

- λ :

-

Scale parameter (MPa)

- ξ :

-

Location parameter (MPa)

- k′ :

-

A certain strength (MPa)

- N d :

-

Number of damaged representative elements

- N :

-

Total number of representative elements

- F(k):

-

Probability distribution function of k

- D :

-

Damage variable

- I 1 * :

-

First stress invariant of representative element (MPa)

- J 2 * :

-

Second deviatoric stress invariant of representative element (MPa2)

- α :

-

A constant related to internal friction angle θ

- θ :

-

Internal friction angle (rad)

- σ :

-

Nominal stress matrix

- σ * :

-

Effective stress matrix

- C :

-

Nominal stiffness matrix

- C * :

-

Effective stiffness matrix

- ε :

-

Strain matrix

- D 0 :

-

Damage of rock sample at the end of initial loading stage

- m(t):

-

Shape parameter at creep time t

- λ(t):

-

Scale parameter at creep time t (MPa)

- k(t):

-

Strength of representative element at creep time t (MPa)

- D c(t):

-

Creep damage

- \(\overline{k}\) :

-

Average strength (MPa)

- m 0 :

-

Shape parameter when t = 0

- λ 0 :

-

Scale parameter when t = 0 (MPa)

- E e :

-

Young's modulus of characteristic representative element (MPa)

- μ e :

-

Poisson's ratio of characteristic representative element

- ε 1(t):

-

Axial strain of characteristic representative element at time t

- ε c(t):

-

Creep strain of characteristic representative element at time t

- σ 1 :

-

Axial pressure (MPa)

- σ 3 :

-

Confining pressure (MPa)

- σ s :

-

Long-term strength (MPa)

- ε st :

-

Strain of stable creep

- ε is :

-

Strain of instable creep

- a 0 :

-

Creep constant

- a 1 :

-

Creep constant (h−1)

- b 0 :

-

Creep constant

- b 1 :

-

Creep constant

- t c :

-

Creep failure time (h)

- t 0 :

-

An amount of time slightly larger than tc (h)

- β :

-

Damage parameter

- ϕ :

-

Damage parameter

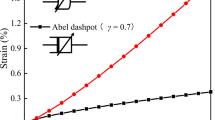

- η γ :

-

Viscosity coefficient of Abel dashpot (MPa·hγ)

- γ :

-

Order of Abel dashpot

- g(t):

-

A function

- a :

-

Interval of function

- b :

-

Interval of function

- a I γt g(t):

-

Left integral of γ-order Riemann–Liouville type of function g(t)

- Γ:

-

Gamma function

- x :

-

Independent variable of integral

- κ :

-

Consistency coefficient (MPa·hn)

- n :

-

Fluidity index

- η a :

-

Apparent viscosity (MPa·h)

- ε e :

-

Strain of Hooke spring

- ε v :

-

Strain of Abel dashpot

- ε vp :

-

Strain of viscoplastic body

- E :

-

Elastic modulus of Hooke spring (MPa)

- δ ij :

-

Kronecker function

- S ij :

-

Deviatoric stress tensor

- e ij :

-

Deviatoric strain tensor

- σ m :

-

Spherical stress tensor

- ε m :

-

Spherical strain tensor

- G 0 :

-

Shear modulus of elastic body (MPa)

- K :

-

Bulk modulus of elastic body (MPa)

- μ :

-

Poisson's ratio of elastic body

- H 1 :

-

Shear viscosity coefficient of Abel dashpot (MPa·hγ)

- F :

-

Yield function (MPa)

- Q :

-

Plastic potential function (MPa)

- F 0 :

-

Reference value of yield function F

- φ(·):

-

A power function with exponent c

- τ :

-

A independent variable

- α′ :

-

A constant related to dilatancy angle θ’

- θ′ :

-

Dilatancy angle (rad)

- σ c :

-

Initiation stress of micro-crack (MPa)

- ε v :

-

Volumetric strain

- C 1 :

-

Cumulative AE count throughout the initial loading stage

- C 2 :

-

Cumulative AE count throughout the constant loading stage

- C 1(σ):

-

Cumulative AE count in the initial loading stage when σ1-σ3 = σ

- R 2 :

-

Correlation coefficient

- C 2(t):

-

Cumulative AE count in the constant loading stage at time t

- T :

-

Temperature (°C)

- ω :

-

Damage parameter associated with the properties of rock and stress (h−1)

- E 0 :

-

Parameter of one-dimensional fractional Nishihara model (MPa)

- E 1 :

-

Parameter of one-dimensional fractional Nishihara model (MPa)

- ηγ 1:

-

Parameter of one-dimensional fractional Nishihara model (MPa·hγ)

- ηγ 2:

-

Parameter of one-dimensional fractional Nishihara model (MPa·hγ)

- G 1 :

-

Parameter of three-dimensional fractional Nishihara model (MPa·hγ)

- H 2 :

-

Parameter of three-dimensional fractional Nishihara model (MPa·hγ)

- ρ :

-

Value of scale parameter λ0 of sample S0 (MPa)

References

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min 35:863–888

Chen BR, Zhao XJ, Feng XT, Zhao HB, Wang SY (2014) Time-dependent damage constitutive model for the marble in the Jinping II hydropower station in China. B Eng Geol Environ 73:499–515

Chen L, Liu JF, Wang CP, Liu J, Wang J (2015) Creeping behavior of Beishan granite under different temperatures and stress conditions. Chin J Rock Mech Eng 34:1228–1235

Chmel A, Shcherbakov I (2013) A comparative acoustic emission study of compression and impact fracture in granite. Int J Rock Mech Min 64:56–59

Ding JY, Zhou HW, Chen Q, Liu D, Liu JF (2015) Characters of rheological damage and constitutive model of salt rock. Rock Soil Mech 36:769–776

Eberhardt E, Stimpson BP, Stead D (1999) Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures. Rock Mech Rock Eng 32:81–99

Feng XT, Young RP, Reyes-Montes JM, Aydan O, Ishida T, Liu JP, Liu HJ (2019) ISRM suggested method for in situ acoustic emission monitoring of the fracturing process in rock masses. Rock Mech Rock Eng 52:1395–1414

He ZL, Zhu ZD, Wu N, Wang Z, Cheng S (2016) Study on time-dependent behavior of granite and the creep model based on fractional derivative approach considering temperature. Math Probl Eng 2016:1–10

Huang P, Zhang JX, Spearing AJS, Chai J, Dong C (2021) Experimental study of the creep properties of coal considering initial damage. Int J Rock Mech Min 139:104629

Hudson JA, Fairhurst C (1969) Tensile strength, Weibull's theory and a general statistical approach to rock failure. In: Teeni M (ed), Proceedings of the Southampton 1969 civil engineering materials conference. Wiley InterScience, Southampton, pp. 901–914

Huy TM, Sulem J, Subrin D (2016) Progressive degradation of rock properties and time-dependent behavior of deep tunnels. Acta Geotech 11:693–711

Lemaitre J (1984) How to use damage mechanics. Nucl Eng Des 80:233–245

Li PF, Zhao XG, Guo Z, Ma LK, Chen L, Wang J (2017) Variation of strength parameters of Beishan granite under triaxial compression. Chin J Rock Mech Eng 36:1599–1610

Li X, Konietzky H, Li XB, Wang Y (2019) Failure pattern of brittle rock governed by initial microcrack characteristics. Acta Geotech 14:1437–1457

Li Y, Chen L, Liu JF, Liu J, Wang CP, Wang J (2018) Experimental study on influence of saturation process and grain size on the fracture toughness of the Beishan granite. Chin J Rock Mech Eng 37:3169–3177

Liang JY, Lu DC, Zhou X, Du XL, Wu W (2019) Non-orthogonal elastoplastic constitutive model with the critical state for clay. Comput Geotech 116:103200

Liu XL, Li DJ, Han C, Shao YM (2022) A Caputo variable-order fractional damage creep model for sandstone considering effect of relaxation time. Acta Geotech 17:153–167

Lu DC, Liang JY, Du XL, Ma C, Gao ZW (2019) Fractional elastoplastic constitutive model for soils based on a novel 3D fractional plastic flow rule. Comput Geotech 105:277–290

Lu DC, Zhou X, Du XL, Wang GS (2019) A 3D fractional elastoplastic constitutive model for concrete material. Int J Solids Struct 165:160–175

Perzyna P (1966) Fundamental problems in viscoplasticity. Adv Appl Mech 9:243–377

Qian L, Zhang JH, Wang XL, Li YH, Zhang R, Xu NW, Li ZG (2021) An improved creep model for granite based on the deviatoric stress-to-peak strength ratio. Arab J Sci Eng 46:5157–5170

Shao JF, Zhu QZ, Su K (2003) Modeling of creep in rock materials in terms of material degradation. Comput Geotech 30:549–555

Szczepanik Z, Milne D, Kostakis K, Eberhardt E (2003) Long term laboratory strength tests in hard rock. In: Handley M (ed), Proceedings of the 10th ISRM congress technology roadmap for rock mechanics. South African Institute of Mining and Metallurgy, Sandton, pp. 1179–1184

Tang H, Wang DP, Duan Z (2020) New Maxwell creep model based on fractional and elastic-plastic elements. Adv Civ Eng 2020:1–11

Tang H, Wang DP, Huang RQ, Pei XJ, Chen WL (2018) A new rock creep model based on variable-order fractional derivatives and continuum damage mechanics. B Eng Geol Environ 77:375–383

Wang LJ, Zhou HW, Rong TL, Ren WG (2018) Research on experimental and nonlinear creep constitutive model of coal at depth. J China Coal Soc 43:2196–2202

Wang QY, Zhu WC, Xu T, Niu LL, Wei J (2017) Numerical simulation of rock creep behavior with a damage-based constitutive law. Int J Geomech 17:04016044

Wang YC, Cong L, Yin XM, Yang XY, Zhang BC, Xiong W (2021) Creep behaviour of saturated purple mudstone under triaxial compression. Eng Geol 288:106159

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Wu F, Chen J, Zou QL (2019) A nonlinear creep damage model for salt rock. Int J Damage Mech 28:758–771

Wu F, Liu JF, Wang J (2015) An improved Maxwell creep model for rock based on variable-order fractional derivatives. Environ Earth Sci 73:6965–6971

Xu HY, Jiang XY (2017) Creep constitutive models for viscoelastic materials based on fractional derivatives. Comput Math Appl 73:1377–1384

Xu WY, Wang RB, Wang W, Zhang ZL, Zhang JC, Wang WY (2012) Creep properties and permeability evolution in triaxial rheological tests of hard rock in dam foundation. J Cent South Univ 19:252–261

Xue DJ, Lu LL, Yi HY, Wu ZD, Zhang QS, Zhang ZP (2021) A fractional Burgers model for uniaxial and triaxial creep of damaged salt-rock considering temperature and volume-stress. Chin J Rock Mech Eng 40:315–329

Yang SQ, Xu P, Ranjith PG, Chen GF, Jing HW (2015) Evaluation of creep mechanical behavior of deep-buried marble under triaxial cyclic loading. Arab J Geosci 8:6567–6582

Zhang JZ, Zhou XP, Zhou LS, Berto F (2019) Progressive failure of brittle rocks with non-isometric flaws: insights from acousto-optic-mechanical (AOM) data. Fatigue Fract Eng M 42:1787–1802

Zhang L, Zhou HW, Wang XY, Wang L, Su T, Wei Q, Deng TF (2022) A triaxial creep model for deep coal considering temperature effect based on fractional derivative. Acta Geotech 17:1739–1751

Zhao J, Feng XT, Yang CX, Zhou YY, Zhang Y (2021) Study on time-dependent fracturing behaviour for three different hard rock under high true triaxial stress. Rock Mech Rock Eng 54:1239–1255

Zhao K, Yang DX, Zeng P, Gong C, Wang XJ, Zhong W (2021) Accelerating creep stage of red sandstone expressed and quantitatively identified based on acoustic emission information. Rock Mech Rock Eng 54:4867–4888

Zhao XG, Cai M, Wang J, Ma LK (2013) Damage stress and acoustic emission characteristics of the Beishan granite. Int J Rock Mech Min 64:258–269

Zheng H, Feng XT, Hao XJ (2015) A creep model for weakly consolidated porous sandstone including volumetric creep. Int J Rock Mech Min 78:99–107

Zhou HW, Su T, Deng HL, Wang R, Zhao JW, Sun XT, An L (2021) Characterizing three-dimensional creep of Beishan granite by the variable-coefficient Abel dashpot. Mech Time-Depend Mat 25:85–100

Zhou HW, Wang CP, Han BB, Duan ZQ (2011) A creep constitutive model for salt rock based on fractional derivatives. Int J Rock Mech Min 48:116–121

Zhou HW, Wang CP, Mishnaevsky L, Duan ZQ, Ding JY (2013) A fractional derivative approach to full creep regions in salt rock. Mech Time-Dep Mat 17:413–425

Zhou RH, Cheng H, Cai HB, Wang XJ, Guo LH (2022) Creep characteristics and creep model of siltstone under triaxial compression and graded unloading. Chin J Rock Mech Eng 41:1136–1147

Zhou X, Lu DC, Du XL, Wang GS, Meng FP (2020) A 3D non-orthogonal plastic damage model for concrete. Comput Method Appl M 360:112716

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (51827901, 52121003, 52142302), the 111 Project (B14006) and the Yueqi Outstanding Scholar Program of CUMTB (2017A03).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, H., Jin, Z. Fractional derivative triaxial creep model of Beishan granite considering probabilistic damage evolution. Acta Geotech. 18, 4017–4033 (2023). https://doi.org/10.1007/s11440-023-01848-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-01848-x