Abstract

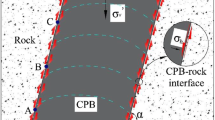

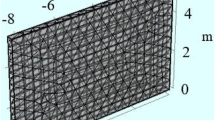

After placement into underground mined-out voids (called stopes), a passive interface loading develops between cemented paste backfill (CPB, an artificially cemented soil) and surrounding rock mass, which results in the spatiotemporal changes in the geomechanical behavior and properties of CPB, and thus affects its field stability. In this study, meter-scale curing columns with rough inner surfaces were developed to investigate the effect of passive interface loading on the geomechanical behavior and properties of CPB, and field-scale stability of CPB mass was conducted through a series of 3D numerical analyses. The obtained results discovered that the passive interface loading not only weakens the compressive and shear behaviors of CPB, but also leads to highly spatiotemporal changes in elastic modulus, unconfined compressive strength, cohesion, and angle of internal friction. Meanwhile, through the integration of the measured degradation in mechanical properties, the field-scale analysis reveals that consideration of stress arching and homogenous mechanical properties substantially overestimate the stability of CPB mass, especially in the narrow stopes with a relatively small height. The simultaneous consideration of stress arching and associated heterogeneous mechanical properties are required for the reliable and accurate assessment of the field stability of CPB mass and its safe engineering design.

Similar content being viewed by others

Data availability

The datasets generated during and analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdul-Hussain N, Fall M (2012) Thermo-hydro-mechanical behaviour of sodium silicate-cemented paste tailings in column experiments. Tunn Undergr Sp Tech 29:85–93. https://doi.org/10.1016/j.tust.2012.01.004

Alagha ASN, Chapman DN (2019) Numerical modelling of tunnel face stability in homogeneous and layered soft ground. Tunn Undergr Sp Tech 94:103096. https://doi.org/10.1016/j.tust.2019.103096

ASTM D3080 , D3080M–11, 2011 Standard test method for direct shear test of soils under consolidated drained conditions ASTM International, West Conshohocken, PA https://doi.org/10.1520/D3080_D3080M-11

ASTM D5084–16a, 2016 Standard test methods for measurement of hydraulic conductivity of saturated porous materials using a flexible wall permeameter West Conshohocken, PA https://doi.org/10.1520/D5084-16A

ASTM D7263–21, 2021 Standard test methods for laboratory determination of density and unit weight of soil specimens ASTM International, West Conshohocken, PA https://doi.org/10.1520/D7263-21

ASTM C39/C39M-18 (2018) Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/C0039_C0039M-18

Čairović Đ, de la Fuente A, Zlámal M, Venclovský J, Girgle F, Januš O et al (2021) Suitability of different tests for characterization of the dimpled concrete-to-concrete interface. Struct Concr 22(2):757–774. https://doi.org/10.1002/suco.201900513

Cao S, Yilmaz E, Yin Z, Xue G, Song W, Sun L (2021) CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cem Concr Compos 116:103865. https://doi.org/10.1016/j.cemconcomp.2020.103865

Chen Z, Ni P, Chen Y, Mei G (2020) Plane-strain consolidation theory with distributed drainage boundary. Acta Geotech 15(2):489–508. https://doi.org/10.1007/s11440-018-0712-z

Cui L, Fall M (2015) A coupled thermo–hydro-mechanical–chemical model for underground cemented tailings backfill. Tunn Undergr Sp Tech 50:396–414. https://doi.org/10.1016/j.tust.2015.08.014

Cui L, Fall M (2016) Mechanical and thermal properties of cemented tailings materials at early ages: influence of initial temperature, curing stress and drainage conditions. Constr Build Mater 125:553–563. https://doi.org/10.1016/j.conbuildmat.2016.08.080

Cui L, Fall M (2016) Multiphysics model for consolidation behavior of cemented paste backfill. Int J Geomech 17(3):04016077. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000743

Cui L, Fall M (2016) An evolutive elasto-plastic model for cemented paste backfill. Comput Geotech 71:19–29. https://doi.org/10.1016/j.compgeo.2015.08.013

Cui L, Fall M (2017) Multiphysics modeling of arching effects in fill mass. Comput Geotech 83:114–131. https://doi.org/10.1016/j.compgeo.2016.10.021

Cui L, Fall M (2017) Modeling of pressure on retaining structures for underground fill mass. Tunn Undergr Sp Tech 69:94–107. https://doi.org/10.1016/j.tust.2017.06.010

Cui L, Fall M (2018) Mathematical modelling of cemented tailings backfill: a review. Int J Min Reclam Env 33(6):389–408. https://doi.org/10.1080/17480930.2018.1453320

Cui L, Fall M (2018) Multiphysics modeling and simulation of strength development and distribution in cemented tailings backfill structures. Int J Concr Struct Mater 12(1):25. https://doi.org/10.1186/s40069-018-0250-y

Do TN, Ou CY (2020) Factors affecting the stability of deep excavations in clay with consideration of a full elastoplastic support system. Acta Geotech 15(7):1707–1722. https://doi.org/10.1007/s11440-019-00886-8

Doherty JP, Hasan A, Suazo GH, Fourie A (2015) Investigation of some controllable factors that impact the stress state in cemented paste backfill. Can Geotech J 52(12):1901–1912. https://doi.org/10.1139/cgj-2014-0321

Fang K, Cui L, Fall M (2020) A coupled chemo-elastic cohesive zone model for backfill-rock interface. Comput Geotech 125:103666. https://doi.org/10.1016/j.compgeo.2020.103666

Fang K, Fall M (2019) Chemically induced changes in the shear behaviour of interface between rock and tailings backfill undergoing cementation. Rock Mech Rock Eng 52(9):3047–3062. https://doi.org/10.1007/s00603-019-01757-0

Ghirian A, Fall M (2014) Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments: part II: mechanical, chemical and microstructural processes and characteristics. Eng Geol 170:11–23. https://doi.org/10.1016/j.enggeo.2013.12.004

Gong W, Tang H, Juang CH, Wang L (2020) Optimization design of stabilizing piles in slopes considering spatial variability. Acta Geotech 15(11):3243–3259. https://doi.org/10.1007/s11440-020-00960-6

Hasan A, Suazo G, Doherty JP, Fourie AB (2014) In situ measurements of cemented paste backfilling in an operating stope at lanfranchi mine. In: Proceedings of the eleventh international symposium on mining with backfill. Perth, p. 327–36

Jiang S, Shen L, Guillard F, Einav I (2021) The effect of cement material properties on the fracture patterns developing within cement-covered brittle sphere under impact. Acta Geotech 16(3):763–773. https://doi.org/10.1007/s11440-020-00959-z

Li L, Aubertin M (2009) A three-dimensional analysis of the total and effective stresses in submerged backfilled stopes. Geotech Geol Eng 27(4):559–569. https://doi.org/10.1007/s10706-009-9257-0

Li L, Aubertin M, Belem T (2005) Formulation of a three dimensional analytical solution to evaluate stresses in backfilled vertical narrow openings. Can Geotech J 42(6):1705–1717. https://doi.org/10.1139/t05-084

Li J, Cao S, Yilmaz E, Liu Y (2022) Compressive fatigue behavior and failure evolution of additive fiber-reinforced cemented tailings composites. Int J Miner Metall Mater 29(2):345–355. https://doi.org/10.1007/s12613-021-2351-x

Libos ILS, Cui L (2020) Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Eng Fract Mech 235:107174. https://doi.org/10.1016/j.engfracmech.2020.107174

Lin Y, Chen F, Lv Y (2021) Analytical solutions for the earth pressure of narrow cohesive backfill with retaining walls rotating about the top. Acta Geotech 16(9):2975–2995. https://doi.org/10.1007/s11440-021-01187-9

Liu N, Cui L, Wang Y (2020) Analytical assessment of internal stress in cemented paste backfill. Adv Mater Sci Eng 2020:6666548. https://doi.org/10.1155/2020/6666548

Liu G, Li L, Yang X, Guo L (2018) Required strength estimation of a cemented backfill with the front wall exposed and back wall pressured. Int J Min Miner Eng 9(1):1–20. https://doi.org/10.1504/ijmme.2018.091214

Marston A (1930) The theory of external loads on closed conduits in the light of the latest experiments. In: Proceedings of the ninth annual meeting of the highway research board. Washington, D.C.,USA, p. 138–70

Sadrossadat E, Basarir H, Luo G, Karrech A, Durham R, Fourie A et al (2020) Multi-objective mixture design of cemented paste backfill using particle swarm optimisation algorithm. Miner Eng 153:106385. https://doi.org/10.1016/j.mineng.2020.106385

Schindler AK (2004) Effect of temperature on hydration of cementitious materials. ACI Mater J 101(1):72–81. https://doi.org/10.1016/j.cemconres.2013.07.006

Shang L, Nguyen H, Bui X, Vu T, Costache R, Hanh LTM (2022) Toward state-of-the-art techniques in predicting and controlling slope stability in open-pit mines based on limit equilibrium analysis, radial basis function neural network, and brainstorm optimization. Acta Geotech 17(4):1295–1314. https://doi.org/10.1007/s11440-021-01373-9

Singalreddy SP, Cui L, Fang K (2022) Spatiotemporal evolution of thermo-hydro-mechanical-chemical processes in cemented paste backfill under interfacial loading. Int J Min Sci Technol. https://doi.org/10.1016/j.ijmst.2022.10.002

Tao J, Yang X, Ding P, Li X, Zhou J, Lu G (2022) A fully coupled thermo-hydro-mechanical-chemical model for cemented backfill application in geothermal conditions. Eng Geol 302:106643. https://doi.org/10.1016/j.enggeo.2022.106643

Terazaghi K (1965) Theoretical soil mechanics. Wiley, New York

Thompson B, Bawden W, Grabinsky M (2012) In situ measurements of cemented paste backfill at the Cayeli Mine. Can Geotech J 49(7):755–772. https://doi.org/10.1139/t2012-040

Wang A, Cao S, Yilmaz E (2022) Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr Build Mater 344:128179. https://doi.org/10.1016/j.conbuildmat.2022.128179

Weilv W, Xu W, Jianpin Z (2021) Effect of inclined interface angle on shear strength and deformation response of cemented paste backfill-rock under triaxial compression. Constr Build Mater 279:122478. https://doi.org/10.1016/j.conbuildmat.2021.122478

Xiapeng P, Fall M, Haruna S (2019) Sulphate induced changes of rheological properties of cemented paste backfill. Miner Eng 141:105849. https://doi.org/10.1016/j.mineng.2019.105849

Yan B, Jia H, Yilmaz E, Lai X, Shan P, Hou C (2022) Numerical study on microscale and macroscale strength behaviors of hardening cemented paste backfill. Constr Build Mater 321:126327. https://doi.org/10.1016/j.conbuildmat.2022.126327

Yan B, Jia H, Yilmaz E, Lai X, Shan P, Hou C (2022) Numerical investigation of creeping rockmass interaction with hardening and shrinking cemented paste backfill. Constr Build Mater 340:127639. https://doi.org/10.1016/j.conbuildmat.2022.127639

Yan B, Lai X, Jia H, Yilmaz E, Hou C (2021) A solution to the time-dependent stress distribution in suborbicular backfilled stope interaction with creeping rock. Adv Civ Eng 2021:5533980. https://doi.org/10.1155/2021/5533980

Yan B, Zhu W, Hou C, Yilmaz E, Saadat M (2020) Characterization of early age behavior of cemented paste backfill through the magnitude and frequency spectrum of ultrasonic P-wave. Constr Build Mater 249:118733. https://doi.org/10.1016/j.conbuildmat.2020.118733

Zhang H, Cao S, Yilmaz E (2022) Influence of 3D-printed polymer structures on dynamic splitting and crack propagation behavior of cementitious tailings backfill. Constr Build Mater 343:128137. https://doi.org/10.1016/j.conbuildmat.2022.128137

Zhang C, Wang J, Song W, Fu J (2022) Pore structure, mechanical behavior and damage evolution of cemented paste backfill. J Mater Res Technol 17:2864–2874. https://doi.org/10.1016/j.jmrt.2022.02.010

Zhang RJ, Zheng YL, Dong CQ, Zheng JJ (2022) Strength behavior of dredged mud slurry treated jointly by cement, flocculant and vacuum preloading. Acta Geotech 17(6):2581–2596. https://doi.org/10.1007/s11440-021-01346-y

Zhao Z, Cao S, Yilmaz E (2022) Effect of layer thickness on flexural property and microstructure of 3D printed rhomboid polymer reinforced cemented tailings composites. Int J Miner Metall Mater in press. https://doi.org/10.1007/s12613-022-2557-6

Zhao X, Fourie A, Qi C (2019) An analytical solution for evaluating the safety of an exposed face in a paste backfill stope incorporating the arching phenomenon. Int J Miner Metall Mater 26(10):1206–1216. https://doi.org/10.1007/s12613-019-1885-7

Funding

This study was funded by the Natural Sciences and Engineering Research Council of Canada (RGPIN-2019–05078).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors have no competing interests to declare that are relevant to the content of this article.

Appendix 1. rock/CPB interface model

The relative interface displacement d∆ is assumed to consist of elastic and plastic parts (i.e., d∆e and d∆p). Correspondingly, the incremental form of the interface stress σ can be expressed by the elastic part of the relative displacement d∆e and interface stiffness Ke:

To evaluate rock/CPB interface behavior, the contribution of interface friction and adhesion was evaluated through Drucker–Prager yield criterion in which the model parameters related to friction and adhesion govern the position of the yield surface.

where I1 and J2 denote the first stress invariant and second deviatoric stress invariant, the yield function parameters αintf and Cintf can be defined in terms of the interface friction angle, δintf, and adhesion, cintf.

A detailed discussion about the determination of interface model parameters can be found in [14]. Moreover, the interface friction angle δintf and adhesion cintf are commonly assumed to be related to the shear strength parameters of CPB materials in practice. To simplify the numerical analysis, the same assumption is adopted in the present study. Correspondingly, δintf = 0.5Φ and cintf = 0.1c are assumed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, L., Singalreddy, S.P. & Guo, G. Geomechanical behavior and properties of cemented paste backfill under passive interface loading and their influences on field-scale stability. Acta Geotech. 18, 3927–3945 (2023). https://doi.org/10.1007/s11440-023-01798-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-01798-4