Abstract

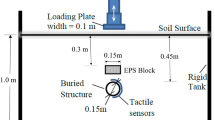

The last half-century has witnessed a proliferation in the use of polyvinyl chloride (PVC) pipes in civil engineering applications. However, little physical data are available to date to assess conformance with performance limits of these pipes subjected to events involving localized ground subsidence. In this study, experimental results are generated and evaluated from a series of physical models involving a buried PVC pipe overlying a localized subsiding bedding zone. Ground subsidence was simulated using a precisely controlled trapdoor system positioned at mid-length of the pipe. A technique including the use of a custom-made displacement transducer was developed as part of this study to facilitate collection of continuous deflection profiles along the axis of the pipes. The progressive development of soil arching was also monitored using earth pressure sensors placed on the top, sides, and at several locations beneath the pipe, both within and beyond the zone of ground subsidence. Strains in the external wall of the pipe were also monitored. The results indicate that significant bending developed in the portion of the pipe traversing the subsidence zone, especially at the pipe crown. Beyond this point, radial deflections of the pipe cross section continued to be detected along the pipe length to distances of approximately four pipe diameters. Ground subsidence induced a severe redistribution of the earth pressures measured in the soil mass surrounding the pipe. A significant increase in vertical soil pressures beneath the pipe was captured within a distance of about one pipe diameter outside the subsidence zone. The overall response of the PVC pipe to localized ground subsidence was found to improve with increasing backfill density and decreasing soil confinement.

Similar content being viewed by others

Abbreviations

- A :

-

Area of pipe wall per unit length of pipe (m2/m)

- B :

-

Width of the trapdoor (m)

- C n :

-

Calibration factor

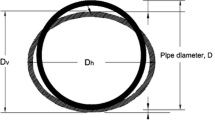

- D :

-

External diameter of the pipe (m)

- D r :

-

Soil relative density (%)

- E p :

-

Elastic modulus of pipe material (GPa)

- H :

-

Soil cover thickness above pipe crown (m)

- I p :

-

Moment of inertia of the pipe wall per unit length (m4/m)

- K :

-

Lateral earth pressure coefficient

- K a :

-

Rankine’s active earth pressure coefficient

- K kr :

-

Krynine’s earth pressure coefficient

- L :

-

Length of the trapdoor (m)

- M s :

-

Secant constrained soil modulus (MPa)

- PS:

-

Pipe stiffness (kN/m/m)

- R :

-

Radius from the center of the pipe to the centroid of the pipe profile (m)

- R H :

-

Correction factor for backfill soil geometry

- S H :

-

Hoop stiffness factor

- q :

-

External surcharge pressure (kPa)

- t :

-

Pipe wall thickness (mm)

- w :

-

Geometry coefficient (m−1)

- Δ:

-

Pipe radial deflection (%)

- ΔT :

-

Pipe total deflection (%)

- γ :

-

Soil unit weight (kN/m3)

- δ :

-

Trapdoor vertical displacement (m)

- ε :

-

Pipe wall strain

- ε bck :

-

Limit strain for buckling

- ε yc :

-

Maximum compressive strain

- ε yt :

-

Maximum service long-term tension strain

- ν s :

-

Poisson ratio of the soil

- σ h :

-

Horizontal pressure in the soil (kPa)

- σ ho :

-

Horizontal pressure prior to yielding of the buried structure (kPa)

- σ v :

-

Vertical pressure in the soil (kPa)

- σ vo :

-

Vertical pressure prior to yielding of the buried structure (kPa)

- ϕ :

-

Internal friction angle of the soil (°)

- ϕ bck :

-

Resistance factor for global buckling

References

American Association of State Highway and Transportation Officials (AASHTO) (2012) AASHTO LRFD bridge design specifications, 2nd edn, Sec. 12, Washington, DC

ASTM (2011) Standard test method for determination of external loading characteristics of plastic pipe by parallel-plate loading—D2412-11, annual book of ASTM standards. ASTM International, West Conshohocken

Balkaya M, Moore ID, Saglamer A (2012) Study of non-uniform bedding due to voids under jointed PVC water distribution pipes. Geotext Geomembr 34:39–50. https://doi.org/10.1016/j.geotexmem.2012.01.003

Benmansour A, Abdallah A, Masrouri F, Auvinet G (1997) Analyse fiabiliste du comportement axial des conduits d’assainissement. Can Geotech J 34:329–343

Brachman RWI, Moore ID, Rowe RK (2000) The design of a laboratory facility for evaluating the structural response of small-diameter buried pipes. Can Geotech J 37:281–295

Bransby MF, Nahas ELA, Turner E, Davies MCR (2007) The interaction of reverse faults with flexible continuous pipelines. Int J Phys Model Geotech 7(3):25–40

Cohen BR (2012) Fixing America’s crumbling underground water infrastructure. Competitive Enterprise Institute. https://cei.org/issue-analysis/fixing-americas-crumbling-underground-water-infrastructure. Accessed 14 Jan 2019

Costa YD, Zornberg JG, Bueno BS, Costa CL (2009) Failure mechanisms in sand over a deep active trapdoor. J Geotech Geoenviron Eng 135(11):1741–1753. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000134

Costa YDJ, Zornberg JG (2020) Active and passive arching stresses outside a deep trapdoor. Acta Geotech. https://doi.org/10.1007/s11440-020-00969-x

Evans CH (1983) An examination of arching in granular soils. M.S. thesis, Massachusetts Institute of Technology, Cambridge

Folkman S (2018) Water main break rates in the USA and Canada: a comprehensive study. Mechanical and Aerospace Engineering Faculty Publications, Paper 174. https://digitalcommons.usu.edu/mae_facpub/174. Accessed 24 Jan 2019

Guo S, Shao Y, Zhang T, Zhu D, Zhang Y (2013) Physical modeling on sand erosion around defective sewer pipes under the influence of groundwater. J Hydraul Eng 139(12):1247–1257. https://doi.org/10.1061/(ASCE)HY.1943-7900.0000785

Hachiya M, Inoue Y, Tohda J, Takatsuka Y, Takagi R (2002) Response of buried pipelines subjected to differential ground settlement. In: Proceedings of the physical modeling in geotechnics (ICPMG’02), Swets & Zeitling Lisse, pp 911–916

Han J, Wang F, Al-Naddaf M, Xu C (2017) Progressive development of two-dimensional soil arching with displacement. Int J Geomech 17(12):04017112. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001025

Handy RL, Spangler MG (2007) Geotechnical engineering: soil and foundation principles and practice, 5th edn. McGraw-Hill, New York

Iglesia GR, Einstein HH, Whitman RV (1999) Determination of vertical loading on underground structures based on an arching evolution concept. In: Fernandez G, Bauer RA (eds) Geo-engineering for underground facilities. ASCE, Reston, pp 495–506

Iglesia GR, Einstein HH, Whitman RV (2014) Investigation of soil arching with centrifuge tests. J Geotech Geoenviron Eng 137(11):1075–1080. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000998

Indiketiya S, Jegatheesan P, Rajeev P, Kuwano K (2019) The influence of pipe embedment material on sinkhole formation due to erosion around defective sewers. Transp Geotech 19:110–125. https://doi.org/10.1016/j.trgeo.2019.03.001

Krizek RJ, Parmelee RA, Kay J, Elnagger H (1971) Structural analysis and design of pipe culverts. National Cooperative Highway Research Program Report, 116, HRB

Krynine DP (1945) Stability and stiffness of cellular cofferdams. Trans ASCE 110:1175–1178 (discussion)

Marshall AM, Klar A, Mair RJ (2010) Tunneling beneath buried pipes: view of soil strain and its effect on pipeline behavior. J Geotech Geoenviron Eng 136(12):1664–1672. https://doi.org/10.1061/_ASCE_GT.1943-5606.0000390

Marston A, Anderson AO (1913) The theory of loads on pipes in ditches and tests of cement and clay drain tile and sewer pipe. Bul. 31, Iowa Eng. Expt. Station

Moser AP, Folkman S (2008) Buried pipe design, 3rd edn. McGraw-Hill, New York City

O’Rourke M, Gadicherla V, Abdoun T (2005) Centrifuge modeling of PGD response of buried pipe. Earthq Eng Eng Vibr 4(1):69–73

Peng SS, Luo Y (1988) Determination of stress field in buried thin pipelines resulting from ground subsidence due to longwall mining. J Min Sci Technol 6(2):205–216

Peter JM, Chapman D, Moore I, Hoult N (2018) Impact of soil erosion voids on reinforced concrete pipe responses to surface loads. Tunn Undergr Space Technol 82:111–124. https://doi.org/10.1016/j.tust.2018.08.003

Rajani B, Zhan C, Kuraoka S (1996) Pipe-soil interaction analysis of jointed water mains. Can Geotech J 33:393–404

Saiyar M, Ni P, Take WA, Moore ID (2016) Response of pipelines of differing flexural stiffness to normal faulting. Géotechnique 66(4):275–286. https://doi.org/10.1680/jgeot.14.P.175

Saiyar M, Take W, Moore I (2011) Validation of boundary PIV measurements of soil–pipe interaction. Int J Phys Modell Geotech 11(1):23–32. https://doi.org/10.1680/ijpmg.2011.11.1.23

Santichaianant K (2002) Centrifuge modeling and analysis of active trapdoor in sand. Ph.D. Thesis, University of Colorado at Boulder

Schlick WJ (1932) Loads on pipe in wide ditches. Bulletin 108, Iowa State, Engineering Experiment Station

Shen SL, Xu YS (2011) Numerical evaluation of land subsidence induced by groundwater pumping in Shanghai. Can Geotech J 48(9):1378–1392. https://doi.org/10.1139/t11-049

Spangler MG (1950) Theory of loads on negative projecting conduits. Proc HRB 30:153–161

Terzaghi K (1943) Theoretical soil mechanics. Wiley, New York

Terzaghi K (1936) Stress distribution in dry and saturated sand above a yielding trap-door. In: Proceedings of the 1st intl conference on soil mechanics and foundation engineering, Cambridge, Mass, pp 35–39

Tohda J, Hachiya M (2005) Response and design of buried pipelines subjected to differential ground settlement. In: Proceedings of the 16th intl conference on soil mechanics and geotechnical engineering. Millpress Science Publishers/IOS Press, pp 1659–1662

Vorster TEB, Klar A, Soga K, Mair RJ (2005) Estimating the effects of tunneling on existing pipelines. J Geotech Geoenviron Eng 131(11):1399–1410

Wang F, Du YJ, Yang XM (2015) Physical modeling on ground responses to tunneling in sand considering the existence of HDPE pipes. Geotech Test J 38(1):85–97. https://doi.org/10.1520/GTJ20140031

Wang B, Li X, Zhou J (2011) Strain analysis of buried steel pipelines across strike-slip faults. J Cent South Univ Technol 18(5):1654–1661

Wang X, Shuai J (2009) Stress and strain analysis of buried pipeline subject to mine subsidence. In: Najafi M, Ma B (eds) Advances and experiences with pipelines and trenchless technology for water, sewer, gas, and oil applications. ASCE, Reston, pp 1219–1228

Watkins RK, Anderson LR (1999) Structural mechanics of buried pipes. CRC Press, Boca Raton

White DJ, Take WA, Bolton MD (2003) Soil deformation measurement using particle image velocimetry (PIV) and photogrammetry. Géotechnique 53(7):619–631. https://doi.org/10.1680/geot.2003.53.7.619

Wols BA, van Thienen P (2014) Modelling the effect of climate change induced soil settling on drinking water distribution pipes. Comput Geotech 55:240–247

Zhou M, Wang F, Du Y-J, Liu MD (2019) Laboratory evaluation of buried high-density polyethylene pipes subjected to localized ground subsidence. Acta Geotech 14(4):1081–1099. https://doi.org/10.1007/s11440-018-0698-6

Acknowledgements

The authors express their gratitude to Prof. Benedito S. Bueno (in memoriam) for his valuable assistance in the development of this work. The authors are also thankful to the Geotechnical Engineering Department of the University of São Paulo at São Carlos, Brazil, and the Civil Engineering Department of the University of Colorado at Boulder, USA, where the first part of this investigation was conducted. Financial support to this research was provided by the Research Foundation of the State of São Paulo, Brazil (FAPESP) (Grant No. 00/09397-0).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Costa, Y.D.J., Zornberg, J.G. & Costa, C.M.L. Physical modeling of buried PVC pipes overlying localized ground subsidence. Acta Geotech. 16, 807–825 (2021). https://doi.org/10.1007/s11440-020-01058-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01058-9