Abstract

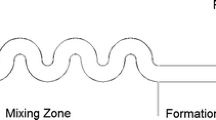

The dynamic behavior of the moving liquid column coalescing with a sessile droplet in triangular microchannels is numerically investigated by using coupled volume of fluid with level set interface tracking method implemented in ANSYS Fluent 14.5 in conjunction with the continuum surface force model. It is found that for both hydrophobic and hydrophilic microchannels, the coalescence between the moving liquid column and droplet can accelerate the original liquid column movement as a result of the induced curvature that lowers the liquid pressure at the interface. As compared to the rectangular microchannel with the same hydraulic diameter, the triangular microchannel exhibits smaller velocity increment ratio because of stronger viscous effect. Simulation results also reveal that the velocity increment ratio increases with the contact angle in hydrophobic microchannels, but it is reverse in the hydrophilic microchannels. The effects of the droplet size, lengthways and transverse positions are also investigated in this work. It is shown that larger droplet and smaller distance between the droplet and inlet or the substrate center can result in larger velocity increment ratio as a result of higher surface energy and lower viscous dissipation energy, respectively. The results obtained in this study create a solid theoretical foundation for designing and optimizing microfluidic devices encountering such a typical phenomenon.

摘要

本文采用 CLSVOF 模型对等边三角形微通道内流动液柱与液滴的聚合特性进行了理论和数值模拟研究。研究结果表明流动液柱与液滴的聚合可以使得液柱速度增加,这主要是由于液柱与液滴聚合过程中界面形态的变化导致了毛细压力的变化,但其速度增率小于同等水力直径的矩形通道。同时考察了壁面浸润性、液滴体积、液滴位置等参数对聚合过程的影响。当壁面亲水性或憎水性越大时,聚合引起的速度增率越大;而液滴体积越大,液滴与进口的纵向距离、偏离壁面中心位置越小时,聚合获得的速度增率也越大。

Similar content being viewed by others

References

Stone HA, Stroock AD, Ajdari A (2004) Engineering flows in small devices, microfluidics toward a lab-on-a-chip. Annu Rev Fluid Mech 36:381–411

Whitesides G, Stroock A (2001) Flexible methods for microfluidics. Phys Today 54:42–48

Juncker D, Schmid H, Drechsler U et al (2002) Autonomous microfluidic capillary system. Anal Chem 74:6139–6144

Yao M, Shah G, Fang J (2012) Highly sensitive and miniaturized fluorescence detection system with an autonomous capillary fluid manipulation chip. Micromachines 3:462–479

Cordero ML, Rolfsnes HO, Burnham DR (2009) Mixing via thermocapillary generation of flow patterns inside a microfluidic drop. New J Phys 11:075033

Okawa D, Pastine SJ, Zettl A et al (2009) Surface tension mediated conversion of light to work. J Am Chem Soc 131:5396–5398

Luong TD, Nguyen NT, Sposito A (2012) Thermocoalescence of microdroplets in a microfluidic chamber. Appl Phys Lett 100:254105

Daniel S, Chaudhury MK, Chen JC (2001) Fast drop movements resulting from the phase change on a gradient surface. Science 291:633–636

Boreyko JB, Chen CH (2009) Self-propelled dropwise condensate on superhydrophobic surfaces. Phys Rev Lett 103:184501

Sellier M, Nock V, Verdier C (2011) Self-propelling, coalescing droplets. Int J Multiph Flow 37:462–468

Liu GL, Kim J, Lu Y et al (2005) Optofluidic control using photothermal nanoparticles. Nat Mater 5:27–32

He XF, Chen R, Liao Q et al (2014) IR laser assisted photothermal condensation in a microchannel. Chem Eng Sci 119:288–294

Chen R, Li SZ, Wang H et al (2015) Dynamic behavior of the liquid flow coalescing with a droplet in hydrophobic microchannels. J Nanosci Nanotechnol 15:2923–2931

Li SZ, Chen R, Wang H et al (2014) Simulation on the coalescence of the moving liquid column and droplet in a hydrophilic microchannel by volume of fluid method. Appl Therm Eng 64:129–138

Hetsroni G, Mosyak A, Segal Z et al (2003) Two-phase flow patterns in parallel micro-channels. Int J Multiph Flow 29:341–360

Kraus T, Günther A, de Mas N et al (2004) An integrated multiphase flow sensor for microchannels. Exp Fluids 36:819–832

Chen YP, Cheng P (2005) Condensation of steam in silicon microchannels. Int Commun Heat Mass 32:175–183

Zhu X, Liao Q, Sui PC et al (2010) Numerical investigation of water droplet dynamics in a low-temperature fuel cell microchannel, effect of channel geometry. J Power Source 195:801–812

Triplett KA, Ghiaasiaan SM, Abdel-Khalik SI et al (1999) Gas–liquid two-phase flow in microchannels part I: two-phase flow patterns. Int J Multiph Flow 25:377–394

Zhao TS, Bi QC (2001) Co-current air–water two-phase flow patterns in vertical triangular microchannels. Int J Multiph Flow 27:765–782

Zhao TS, Liao Q (2002) Theoretical analysis of film condensation heat transfer inside vertical mini triangular channels. Int J Heat Mass Transf 45:2829–2842

Liao Q, Zhao TS (2003) Modeling of Taylor bubble rising in a vertical mini noncircular channel filled with a stagnant liquid. Int J Multiph Flow 29:411–434

Peles YP, Haber S (2000) A steady state, one dimensional, model for boiling two phase flow in triangular micro-channel. Int J Multiph Flow 26:1095–1115

Rahmat M, Hubert P (2010) Two-phase simulations of micro heat pipes. Comput Fluids 39:451–460

Jenson RM, Wollman AP, Weislogel MM et al (2014) Passive phase separation of microgravity bubbly flows using conduit geometry. Int J Multiph Flow 65:68–81

Hirt CW, Nichols BD (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39:201–225

Osher S, Sethian JA (1988) Fronts propagating with curvature-dependent speed, algorithms based on Hamilton-Jacobi formulations. J Comput Phys 79:12–49

Chen S, Doolen GD (1988) Lattice Boltzmann method for fluid flows. Annu Rev Fluid Mech 30:329–364

Hou TY, Lowengrub JS, Shelley MJ (2001) Boundary integral methods for multicomponent fluids and multiphase materials. J Comput Phys 169:302–362

Renardy Y, Renardy M (2002) PROST: a parabolic reconstruction of surface tension for the volume-of-fluid method. J Comput Phys 183:400–421

Sussman M, Puckett EG (2000) A coupled level set and volume-of-fluid method for computing 3D and axisymmetric incompressible two-phase flows. J Comput Phys 162:301–337

Chakraborty I, Biswas G, Ghoshdastidar PS (2011) Bubble generation in quiescent and co-flowing liquids. Int J Heat Mass Transf 54:4673–4688

Sun DL, Tao WQ (2010) A coupled volume-of-fluid and level set (VOSET) method for computing incompressible two-phase flows. Int J Heat Mass Transf 53:645–655

Albadawi A, Donoghue DB, Robinson AJ et al (2013) On the analysis of bubble growth and detachment at low capillary and bond numbers using volume of fluid and level set methods. Chem Eng Sci 90:77–91

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100:335–354

Youngs DL (1982) Time-dependent multi-material flow with large fluid distortion. Numer Methods Fluid Dyn 24:273–285

Rohsenow WM, Hartnett JP, Cho YI (1998) Handbook of heat transfer, 3rd edn. McGraw-Hill Professional, New York

Gan Y, Xu J, Yan Y (2015) An experimental study of two-phase pressure drop of acetone in triangular silicon micro-channels. Appl Therm Eng 80:76–86

Liao Q, Li SZ, Chen R (2015) Coalescence with multi-droplets caused acceleration of the liquid movement in microchannels. Ind Eng Chem Res 54:1161–1169

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51222603, 51276208 and 51325602), the Fundamental Research Funds for the Central Universities (CDJZR12148801) and Program for New Century Excellent Talents in University (NCET-12-0591).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

About this article

Cite this article

Li, S., Chen, R., Wang, H. et al. Numerical investigation of the moving liquid column coalescing with a droplet in triangular microchannels using CLSVOF method. Sci. Bull. 60, 1911–1926 (2015). https://doi.org/10.1007/s11434-015-0924-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-015-0924-7