Abstract

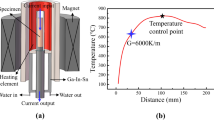

Phase selection and microstructure evolution of the undercooled eutectic Ti-Si alloy were systematically investigated by the electromagnetic levitation method, and the maximum undercooling achieved was 318 K (0.2TE). The migration of the liquid-solid interface was in-situ detected by a high-speed camera system. When the undercooling is smaller than 140 K, the liquid-solid interface is smooth. Once the undercooling arrives at 230 K, the liquid-solid interface is irregular, which reflects the growth transition from the solute control to the combined controls of solute and thermal. The eutectic growth velocity increases as an exponential function of undercooling. The electromagnetic stirring effect makes it difficult to increase undercooling, but plays an important role in accelerating the eutectic reaction velocity at low and moderate undercoolings. Primary dendritic β-Ti phase appears in the solidified alloy from 63 to 176 K undercoolings, and the microstructure is completely composed of eutectic once the undercoolings increase up to 230 K. When the undercoolings exceed 273 K, the microstructure consists of uniformly distributed irregular eutectic. For the drop tube experiments, the microstructures composed of a large amount of dendritic α-Ti phase and eutectic phase are found in a wide range of diameters from 69 to 725 µm. As the decrease of diameter, the solubility of Si in the dendritic α-Ti phase dramatically increases from 6.80% to 10.73%, and the ratio of the area occupied by the dendritic α-Ti on a cross-section of solidified alloy obviously increases from 23.52% to 41.02%, which result from the combined effects of high undercooling and large cooling rate.

Similar content being viewed by others

References

Liu G, Zhang G J, Jiang F, et al. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat Mater, 2013, 12: 344–350

Löser W, Leonhardt M, Lindenkreuz H G, et al. Phase selection in undercooled binary peritectic alloy melts. Mater Sci Eng-A, 2004, 375–377: 534–539

Wu Y H, Chang J, Wang W L, et al. Metastable coupled-growth kinetics between primary and peritectic phases of undercooled hypoperitectic Fe54.5Ti45.5 alloy. Appl Phys Lett, 2016, 109: 154101

Wang Q, Zhai B, Wang H P, et al. Atomic structure of liquid refractory Nb5Si3 intermetallic compound alloy based upon deep neural network potential. J Appl Phys, 2021, 130: 185103

Zhang P C, Hu Y J, Chang J, et al. Microscopic hardness and dynamic mechanical analysis of rapidly solidified Fe-based amorphous alloys. J Alloys Compd, 2021, 861: 157957

Yang T, Han Y, Li J. Manipulating silver dendritic structures via diffusion and reaction. Chem Eng Sci, 2015, 138: 457–464

Luo Z C, Wang H P. Primary dendrite growth kinetics and rapid solidification mechanism of highly undercooled Ti−Al alloys. J Mater Sci Tech, 2020, 40: 47–53

Sun G, Xu J, Harrowell P. The mechanism of the ultrafast crystal growth of pure metals from their melts. Nat Mater, 2018, 17: 881–886

Vekilov P G. Nucleation. Cryst Growth Des, 2010, 10: 5007–5019

Wang H P, Lü P, Cai X, et al. Rapid solidification kinetics and mechanical property characteristics of Ni−Zr eutectic alloys processed under electromagnetic levitation state. Mater Sci Eng-A, 2020, 772: 138660

Trivedi R, Magnin P, Kurz W. Theory of eutectic growth under rapid solidification conditions. Acta Metall, 1987, 35: 971–980

Lipton J, Kurz W, Trivedi R. Rapid dendrite growth in undercooled alloys. Acta Metall, 1987, 35: 957–964

Hu L, Yang S J, Wang L, et al. Dendrite growth kinetics of β-Zr phase within highly undercooled liquid Zr−Si hypoeutectic alloys under electrostatic levitation condition. Appl Phys Lett, 2017, 110: 164101

Liu L, Li J F, Zhou Y H. Solidification interface morphology pattern in the undercooled Co-24.0at.% Sn eutectic melt. Acta Mater, 2011, 59: 5558–5567

Lee B, Paek E, Mitlin D, et al. Sodium metal anodes: Emerging solutions to dendrite growth. Chem Rev, 2019, 119: 5416–5460

Sun C T, Xue D F. Chemical bonding in micro-pulling down process: High throughput single crystal growth. Sci China Tech Sci, 2018, 61: 1776–1778

Jeon S, Heo T, Hwang S Y, et al. Reversible disorder-order transitions in atomic crystal nucleation. Science, 2021, 371: 498–503

Lutsko J F, Nicolis G. Theoretical evidence for a dense fluid precursor to crystallization. Phys Rev Lett, 2006, 96: 046102

Xu M, Ge X, Yao W, et al. Atomic distance tuning effect for nucleation in liquid iron. Metall Mat Trans A, 2018, 49: 4419–4423

Mullis A M, Clopet C R. On the origin of anomalous eutectic growth from undercooled melts: Why re-melting is not a plausible explanation. Acta Mater, 2018, 145: 186–195

Luo S B, Wang W L, Xia Z C, et al. Theoretical prediction and experimental observation for microstructural evolution of undercooled nickel-titanium eutectic type alloys. J Alloys Compd, 2017, 692: 265–273

Zhao J F, Wang H P, Wei B. A new thermodynamically stable Nb2Ni intermetallic compound phase revealed by peritectoid transition within binary Nb−Ni alloy system. J Mater Sci Tech, 2022, 100: 246–253

Zhang X, Chen Y, Hu J. Recent advances in the development of aerospace materials. Prog Aerospace Sci, 2018, 97: 22–34

Chen G, Peng Y, Zheng G, et al. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat Mater, 2016, 15: 876–881

Shuleshova O, Holland-Moritz D, Löser W, et al. In situ observations of solidification processes in γ-TiAl alloys by synchrotron radiation. Acta Mater, 2010, 58: 2408–2418

Liu W, Yan N, Wang H P. Dendritic morphology evolution and microhardness enhancement of rapidly solidified Ni-based superalloys. Sci China Tech Sci, 2019, 62: 1976–1986

Liu T, Luo L S, Zhang D H, et al. Comparison of microstructures and mechanical properties of as-cast and directionally solidified Ti−47Al−1W−0.5Si alloy. J Alloys Compd, 2016, 682: 663–671

Wang Q, Wang H P, Geng D L, et al. Experimental determination of the Ni−Ni5Zr eutectic point for binary Ni−Zr alloy phase diagram. Appl Phys A, 2020, 126: 375

Matson D M, Xiao X, Rodriguez J E, et al. Use of thermophysical properties to select and control convection during rapid solidification of steel alloys using electromagnetic levitation on the space station. JOM, 2017, 69: 1311–1318

Luo Z C, Wang H P. Combined effects of high undercooling and large cooling rate on the microstructure evolution and hardening mechanism of rapidly solidified Ti−Al alloys. Metall Mater Trans A, 2020, 51: 1242–1253

Wu Y H, Chang J, Wang W L, et al. A triple comparative study of primary dendrite growth and peritectic solidification mechanism for undercooled liquid Fe59Ti41 alloy. Acta Mater, 2017, 129: 366–377

Franke P, Seifert H J. Ternary Steel Systems: Phase Diagrams and Phase Transition Data. Springer, 2012

Lin M J, Chang J, Wu Y H, et al. Fluid convection and solidification mechanisms of liquid Fe50Cu50 alloy under electromagnetic levitation condition. Acta Phys Sin, 2017, 66: 136401

Ishikawa T, Paradis P F, Okada J T, et al. Viscosity measurements of molten refractory metals using an electrostatic levitator. Meas Sci Technol, 2012, 23: 025305

Rhim W K, Ohsaka K. Thermophysical properties measurement of molten silicon by high-temperature electrostatic levitator: Density, volume expansion, specific heat capacity, emissivity, surface tension and viscosity. J Cryst Growth, 2000, 208: 313–321

Kurz W, Fisher D J. Fundamentals of Solidification. 4th ed. Beijing: Higher Education Press, 2010. 18–28

Kang L J, Piao F Y. General Chemistry. 4th ed. Beijing: Higher Education Press, 2005. 20–40

Li M X, Wang H P, Yan N, et al. Heat transfer of micro-droplet during free fall in drop tube. Sci China Tech Sci, 2018, 61: 1021–1030

Lee E S, Ahn S. Solidification progress and heat transfer analysis of gas-atomized alloy droplets during spray forming. Acta Metall Mater, 1994, 42: 3231–3243

Smithells C J. Metals Reference Book. 6th ed. London: Butterworth, 1984

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2018YFB2001800), and the National Natural Science Foundation of China (Grant Nos. 51734008, 51771154, and 52088101). We are grateful to Miss. Wang Xiaojuan, Mr. Zuo Dongdong and Dr. Cai Xiao for their help of experiment. We are especially grateful to Prof. Wei Bingbo for the experimental support.

Rights and permissions

About this article

Cite this article

Luo, Z., Chang, J. & Wang, H. Phase selection and microstructure evolution within eutectic Ti-Si alloy solidified at containerless state. Sci. China Technol. Sci. 65, 1587–1598 (2022). https://doi.org/10.1007/s11431-021-1992-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-021-1992-1