Abstract

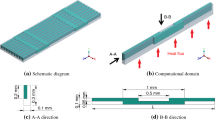

The conventional straight microchannel heat sinks have been reported to inadequately remove the increasing power density of electronics. In recent years, an effective heat transfer enhancement method, flow disruptions have attracted the attention of researchers, where interrupted structures are arranged in the microchannel to enhance flow mixing and heat transfer. However, previous numerical studies of interrupted microchannel heat sinks (I MCHS) mainly focus on single-phase flow condition, and the characteristics of the boiling heat transfer of I MCHS in two-phase flow condition have been rarely explored. Thus, the flow and heat transfer characteristics of two I MCHS based on rectangular microchannel heat sink (R MCHS) are investigated by modeling both single-phase and two-phase flow conditions. These two interrupts consist of a combination of cavities and ribs, namely elliptical cavities and elliptical side ribs (EC-ESR), and elliptical cavities and elliptical central ribs (EC-ECR). The results show that for single-phase flow condition, the maximum Nusselt number is increased by 187% in the EC-ESR design and 150% in the EC-ECR design compared with the R MCHS. For subcooled boiling (i.e., two-phase flow) condition, the EC-ECR design is a promising structure to enhance boiling heat transfer with 6.7 K reduction of average wall temperature and 29% increment of local heat transfer coefficient when compared with those of R MCHS. However, the local heat transfer coefficient in the EC-ESR design is decreased by 22% compared with the R MCHS due to the formation of a rare flow pattern (i.e., inverted annular flow with vapor film separation) in the microchannel. This flow pattern can induce departure from nucleate boiling (DNB), thereby deteriorating the heat transfer on the channel walls.

Similar content being viewed by others

References

Tuckerman D B, Pease R. High-performance heat sinking for VLSI. IEEE Electron Device Lett, 1981, 2: 126–129

Alihosseini Y, Zabetian Targhi M, Heyhat M M, et al. Effect of a micro heat sink geometric design on thermo-hydraulic performance: A review. Appl Thermal Eng, 2020, 170: 114974

Japar W M A A, Sidik N A C, Mat S. A comprehensive study on heat transfer enhancement in microchannel heat sink with secondary channel. Int Commun Heat Mass Transfer, 2018, 99: 62–81

Sidik N A C, Muhamad M N A W, Japar W M A A, et al. An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int Commun Heat Mass Transfer, 2017, 88: 74–83

Li Y H, Wu Z H, Xie H Q, et al. Study on the performance of TEG with heat transfer enhancement using graphene-water nanofluid for a TEG cooling system. Sci China Tech Sci, 2017, 60: 1168–1174

Shen H, Xie G, Wang C C. Heat transfer and thermodynamic analysis by introducing multiple alternation structures into double-layer microchannel heat sinks. Int J Thermal Sci, 2019, 145: 105975

Hu D H, Zhang Z W, Li Q. Numerical study on flow and heat transfer characteristics of microchannel designed using topological optimizations method. Sci China Tech Sci, 2019, 63: 105–115

Li W, Wang Z, Yang F, et al. Supercapillary architecture-activated two-phase boundary layer structures for highly stable and efficient flow boiling heat transfer. Adv Mater, 2020, 32: 1905117

Li C, Wang Z, Wang P I, et al. Nanostructured copper interfaces for enhanced boiling. Small, 2008, 4: 1084–1088

Deng D X, Chen X L, Chen L, et al. Preparation of porous structures on copper microchannel surfaces by laser writing. Sci China Tech Sci, 2019, 62: 2261–2270

Zhang J F, Jia L, Yang W W, et al. Numerical analysis and parametric optimization on flow and heat transfer of a microchannel with longitudinal vortex generators. Int J Thermal Sci, 2019, 141: 211–221

Xu F, Pan Z, Wu H. Experimental investigation on the flow transition in different pin-fin arranged microchannels. Microfluid Nanofluid, 2018, 22: 11

Liu H, Qi D, Shao X, et al. An experimental and numerical investigation of heat transfer enhancement in annular microchannel heat sinks. Int J Thermal Sci, 2019, 142: 106–120

Huang B, Li H, Xu T. Experimental investigation of the flow and heat transfer characteristics in microchannel heat exchangers with reentrant cavities. Micromachines, 2020, 11: 403

Ahmed H E, Ahmed M I. Optimum thermal design of triangular, trapezoidal and rectangular grooved microchannel heat sinks. Int Commun Heat Mass Transfer, 2015, 66: 47–57

Chai L, Xia G D, Wang H S. Numerical study of laminar flow and heat transfer in microchannel heat sink with offset ribs on sidewalls. Appl Thermal Eng, 2016, 92: 32–41

Rehman M M U, Cheema T A, Ahmad F, et al. Thermodynamic assessment of microchannel heat sinks with novel sidewall ribs. J Thermophys Heat Transfer, 2020, 34: 243–254

Shen H, Wang C C, Xie G. A parametric study on thermal performance of microchannel heat sinks with internally vertical bifurcations in laminar liquid flow. Int J Heat Mass Transfer, 2018, 117: 487–497

Ebrahimi A, Roohi E, Kheradmand S. Numerical study of liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Appl Thermal Eng, 2015, 78: 576–583

Cao Z, Xu J. Modulated heat transfer tube with short conical-mesh inserts: A linking from microflow to macroflow. Int J Heat Mass Transfer, 2015, 89: 291–307

Deng D, Chen L, Chen X, et al. Heat transfer and pressure drop of a periodic expanded-constrained microchannels heat sink. Int J Heat Mass Transfer, 2019, 140: 678–690

Xu J L, Gan Y H, Zhang D C, et al. Microscale heat transfer enhancement using thermal boundary layer redeveloping concept. Int J Heat Mass Transfer, 2005, 48: 1662–1674

Lu G, Zhai X. Analysis on heat transfer and pressure drop of a microchannel heat sink with dimples and vortex generators. Int J Thermal Sci, 2019, 145: 105986

Li Y F, Xia G D, Ma D D, et al. Characteristics of laminar flow and heat transfer in microchannel heat sink with triangular cavities and rectangular ribs. Int J Heat Mass Transfer, 2016, 98: 17–28

Ghani I A, Kamaruzaman N, Sidik N A C. Heat transfer augmentation in a microchannel heat sink with sinusoidal cavities and rectangular ribs. Int J Heat Mass Transfer, 2017, 108: 1969–1981

Sikdar P, Datta A, Biswas N, et al. Identifying improved microchannel configuration with triangular cavities and different rib structures through evaluation of thermal performance and entropy generation number. Phys Fluids, 2020, 32: 033601

Alfellag M A, Ahmed H E, Fadhil O T, et al. Optimal hydrothermal design of microchannel heat sink using trapezoidal cavities and solid/slotted oval pins. Appl Thermal Eng, 2019, 158: 113765

Mukherjee A, Kandlikar S G. Numerical simulation of growth of a vapor bubble during flow boiling of water in a microchannel. Microfluid Nanofluid, 2005, 1: 137–145

Lin Y, Luo Y, Li W, et al. Numerical study of flow reversal during bubble growth and confinement of flow boiling in microchannels. Int J Heat Mass Transfer, 2021, 177: 121491

Yu W, Xu L, Chen S, et al. Numerical study on flow boiling in a tree-shaped microchannel. Fractals, 2019, 27: 1950111

Lee H, Agonafer D D, Won Y, et al. Thermal modeling of extreme heat flux microchannel coolers for GaN-on-SiC semiconductor devices. J Electron Packaging, 2016, 138: 010907

Luo Y, Li J, Zhou K, et al. A numerical study of subcooled flow boiling in a manifold microchannel heat sink with varying inlet-to-outlet width ratio. Int J Heat Mass Transfer, 2019, 139: 554–563

Luo Y, Zhang J, Li W. A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements. Int J Heat Mass Transfer, 2020, 156: 119864

Lin Y, Luo Y, Li W, et al. Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. Int J Heat Mass Transfer, 2021, 171: 121118

Lin Y, Luo Y, Li W, et al. Enhancement of flow boiling heat transfer in microchannel using micro-fin and micro-cavity surfaces. Int J Heat Mass Transfer, 2021, 179: 121739

Chen H, Li Q. Experimental study of a novel heat sink for distribution level static synchronous compensator cooling. Sci China Tech Sci, 2020, 63: 1764–1775

Lee W H. A pressure iteration scheme for two-phase flow modelling. Veziroglu T N, ed. Multiphase Transport Fundamentals, Reactor Safety, Applications. Hemisphere, Washington D C, 1980. 61–82

Chen L G, Yang A B, Feng H J, et al. Constructal design progress for eight types of heat sinks. Sci China Tech Sci, 2020, 63: 879–911

Xia G, Zhai Y, Cui Z. Numerical investigation of thermal enhancement in a micro heat sink with fan-shaped reentrant cavities and internal ribs. Appl Thermal Eng, 2013, 58: 52–60

Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys, 1981, 39: 201–225

Sun D, Xu J, Ding P. Numerical research on relationship between flow pattern transition and condensation heat transfer in microchannel. Eng Computations, 2014, 31: 939–956

Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension. J Comput Phys, 1992, 100: 335–354

Lee H, Kharangate C R, Mascarenhas N, et al. Experimental and computational investigation of vertical downflow condensation. Int J Heat Mass Transfer, 2015, 85: 865–879

Pan Z, Shen Y, Wu H. Saturated flow boiling of isolated seed bubble across a heated square cylinder in two-dimensional microchannel. Int J Heat Mass Transfer, 2020, 157: 119885

Pan Z, Weibel J A, Garimella S V. Spurious current suppression in VOF-CSF simulation of slug flow through small channels. Numer Heat Transfer Part A-Appl, 2015, 67: 1–12

Li Y F, Xia G D, Ma D D, et al. Experimental investigation of flow boiling characteristics in microchannel with triangular cavities and rectangular fins. Int J Heat Mass Transfer, 2020, 148: 119036

Galvis E, Culham R. Measurements and flow pattern visualizations of two-phase flow boiling in single channel microevaporators. Int J Multiphase Flow, 2012, 42: 52–61

Chen L, Tian Y S, Karayiannis T G. The effect of tube diameter on vertical two-phase flow regimes in small tubes. Int J Heat Mass Transfer, 2006, 49: 4220–4230

Gan Y, Xu J, Yan Y. An experimental study of two-phase pressure drop of acetone in triangular silicon micro-channels. Appl Thermal Eng, 2015, 80: 76–86

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National MCF Energy R&D Program (Grant No. 2018YFE0312300), the National Natural Science Foundation of China (Grant No. 51706100), the Natural Science Foundation of Jiangsu Province (Grant No. BK20180477), and the Fundamental Research Funds for the Central Universities (Grant No. 30918011205).

Supporting Information

The supporting information is available online at tech.scichina.com and link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Electronic supplementary material

Supplementary material, approximately 504 KB.

Rights and permissions

About this article

Cite this article

Zhou, J., Chen, X. & Li, Q. Numerical study on two-phase boiling heat transfer performance of interrupted microchannel heat sinks. Sci. China Technol. Sci. 65, 679–692 (2022). https://doi.org/10.1007/s11431-021-1923-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-021-1923-1