Abstract

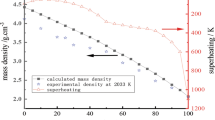

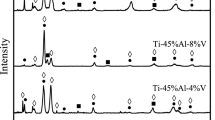

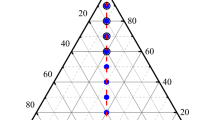

Electrostatic levitation technique and molecular dynamics simulation were performed to investigate the thermophysical properties, liquid structure and crystal growth dependence on undercooling of Ti85Ni10Al5 alloy. The liquid Ti85Ni10Al5 alloy was substantially undercooled up to 335 K (0.18TL). As undercooling increased, the potential energy of the liquid alloy decreased and the alloy entered into a high metastable state. At this state, the atoms tended to bond with each other and the clusters were inclined to convert into high-coordinated clusters, as confirmed by the fraction of the high-coordinated clusters variation. The enlarged clusters and enhanced local structure stability contributed to the increase of the thermophysical parameters and crystal growth velocity, and eventually dendrite refinement. The density, the specific heat and the surface tension of liquid alloy exhibited a linear relation with temperature and the shear viscosity of liquid alloy showed exponential variation which showed good agreement with the calculation results by molecular dynamics simulation. The growth velocity first increased slowly and then dramatically once the undercooling exceeded the threshold. The achieved maximum crystal growth velocity was 12.4 ms−1 and it was up to 326 times of the value at 94 K undercooling.

Similar content being viewed by others

References

Mohr M, Wunderlich R, Novakovic R, et al. Precise measurements of thermophysical properties of liquid Ti-6Al-4V (Ti64) alloy on board the international space station. Adv Eng Mater, 2020, 22: 2000169

Jakse N, Pasturel A. Liquid-liquid phase transformation in silicon: Evidence from first-principles molecular dynamics simulations. Phys Rev Lett, 2007, 99: 205702

Ruan Y, Hu L, Yan N, et al. Recent advances and future perspectives of space materials science (in Chinese). Sci Sin Tech, 2020, 50: 603–649

Haxhimali T, Karma A, Gonzales F, et al. Orientation selection in dendritic evolution. Nat Mater, 2006, 5: 660–664

Akamatsu S, Bottin-Rousseau S, Faivre G, et al. Scaling theory of two-phase dendritic growth in undercooled ternary melts. Phys Rev Lett, 2014, 112: 105502

Rhim W K, Chung S K, Barber D, et al. An electrostatic levitator for high-temperature containerless materials processing in 1-g. Rev Sci Instruments, 1993, 64: 2961–2970

Paradis P F, Ishikawa T, Lee G W, et al. Materials properties measurements and particle beam interactions studies using electrostatic levitation. Mater Sci Eng-R-Rep, 2014, 76: 1–53

Hu L, Wang W L, Yang S J, et al. Dendrite growth within supercooled liquid tungsten and tungsten-tantalum isomorphous alloys. J Appl Phys, 2017, 121: 085901

Paradis P F, Ishikawa T, Yoda S. Noncontact density measurements of tantalum and rhenium in the liquid and undercooled states. Appl Phys Lett, 2003, 83: 4047–4049

Rhim W K, Ohsaka K, Paradis P F, et al. Noncontact technique for measuring surface tension and viscosity of molten materials using high temperature electrostatic levitation. Rev Sci Instrum, 1999, 70: 2796–2801

Lee G W, Jeon S, Park C, et al. Crystal-liquid interfacial free energy and thermophysical properties of pure liquid Ti using electrostatic levitation: Hypercooling limit, specific heat, total hemispherical emissivity, density, and interfacial free energy. J Chem ThermoDyn, 2013, 63: 1–6

Kurz W, Giovanola B, Trivedi R. Theory of microstructural development during rapid solidification. Acta Metall, 1986, 34: 823–830

Boettinger W J, Coriell S R, Greer A L, et al. Solidification microstructures: Recent developments, future directions. Acta Mater, 2000, 48: 43–70

Battersby S E, Cochrane R F, Mullis A M. Growth velocity-undercooling relationships and microstructural evolution in undercooled Ge and dilute Ge-Fe alloy. J Mater Sci, 1999, 34: 2049–2056

Kostov A, Friedrich B. Predicting thermodynamic stability of crucible oxides in molten titanium and titanium alloys. Comput Mater Sci, 2006, 38: 374–385

Frommeyer G, von Czarnowski P. High strain rate superplasticity and strength properties of two-phase α-titanium: intermetallic Ti-12Co-5Al and Ti-12Ni-5Al alloys. Int J Mater Res, 1990, 81: 756–760

Liu Q, Yang W, Chen G. On superplasticity of two phase α-titanium—intermetallic Ti-(Co,Ni)-Al alloys. Acta Metall Mater, 1995, 43: 3571–3582

Lee B J, Baskes M I, Kim H, et al. Second nearest-neighbor modified embedded atom method potentials for bcc transition metals. Phys Rev B, 2001, 64: 184102

Kim Y K, Kim H K, Jung W S, et al. Development and application of Ni-Ti and Ni-Al-Ti 2NN-MEAM interatomic potentials for Ni-base superalloys. Comp Mater Sci, 2017, 139: 225–233

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys, 1995, 117: 1–19

Rösner-Kuhn M, Drewes K, Franz H, et al. Enthalpy measurements of the solid high-temperature β-phase of titanium and zirconium by levitation drop calorimetry. J Alloys Compd, 2001, 316: 175–178

Rhim W K, Ohsaka K. Thermophysical properties measurement of molten silicon by high-temperature electrostatic levitator: Density, volume expansion, specific heat capacity, emissivity, surface tension and viscosity. J Cryst Growth, 2000, 208: 313–321

Feng J Q, Beard K V. Small-amplitude oscillations of electrostatically levitated drops. Proc R Soc Lond A, 1990, 430: 133–150

Egry I. On the relation between surface tension and viscosity for liquid metals. Scripta Metall Mater, 1993, 28: 1273–1276

Nijmeijer M J P, Bakker A F, Bruin C, et al. A molecular dynamics simulation of the Lennard-Jones liquid-vapor interface. J Chem Phys, 1988, 89: 3789–3792

Li L H, Hu L, Yang S J, et al. Thermodynamic properties and solidification kinetics of intermetallic Ni7Zr2 alloy investigated by electrostatic levitation technique and theoretical calculations. J Appl Phys, 2016, 119: 035902

Zhang Y, Mattern N, Eckert J. Atomic structure and transport properties of Cu50Zr45Al5 metallic liquids and glasses: Molecular dynamics simulations. J Appl Phys, 2011, 110: 093506

Allen M P, Tildesley D J. Computer Simulation of Liquids. 2nd ed. New York: Oxford University Press, 1989. 46–94

Holian B L, Evans D J. Shear viscosities away from the melting line: A comparison of equilibrium and nonequilibrium molecular dynamics. J Chem Phys, 1983, 78: 5147–5150

Zhao J F, Wang H P, Zou P F, et al. Liquid structure and thermophysical properties of ternary Ni-Fe-Co alloys explored by molecular dynamics simulations and electrostatic levitation experiments. Metall Mater Trans A, 2021, 52: 1732–1748

Su Y, Mohr M, Wunderlich R K, et al. The relationship between viscosity and local structure in liquid zirconium via electromagnetic levitation and molecular dynamics simulations. J Mol Liquids, 2020, 298: 111992

Hu L, Yang S J, Wang L, et al. Dendrite growth kinetics of βZr phase within highly undercooled liquid Zr-Si hypoeutectic alloys under electrostatic levitation condition. Appl Phys Lett, 2017, 110: 164101

Aziz M J. Model for solute redistribution during rapid solidification. J Appl Phys, 1982, 53: 1158–1168

Kavousi S, Novak B R, Hoyt J, et al. Interface kinetics of rapid solidification of binary alloys by atomistic simulations: Application to Ti-Ni alloys. Comput Mater Sci, 2020, 184: 109854

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. U1806219, 52073232, 52088101 and U1660108), the Science Fund for Distinguished Young Scholars of Shaanxi Province (Grant No. 2020JC-11), and the Science Fund for Scientific and Technological Innovation Team of Shaanxi Province (Grant No. 2021TD-14). The authors are grateful to Dr. Delu Geng, Mr. Chenhui Zheng, Mr. Jiongfei Zhao and Ms. Tingting Xu for their helpful discussion.

Rights and permissions

About this article

Cite this article

Xiao, R., Ruan, Y., Lin, M. et al. Metastable liquid properties and rapid crystal growth of Ti-Ni-Al alloy investigated by electrostatic levitation and molecular dynamics simulation. Sci. China Technol. Sci. 64, 2200–2210 (2021). https://doi.org/10.1007/s11431-021-1859-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-021-1859-1