Abstract

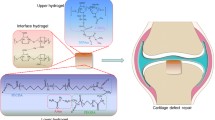

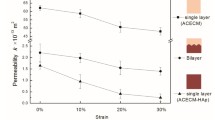

Osteochondral defects are most commonly characterized by damages to both cartilage and underlying subchondral bone tissues, thus developing bi-layered scaffold that can concurrently regenerate these two specific lineages becomes challenge. In this study, the highly biomimetic bi-layered scaffolds were successfully prepared using human-like-collagen (HLC), hyaluronan (HA) and nano hydroxyapatite (HAP) particles, combined with “liquid phase synthesis” technology, freeze-drying and chemical cross-linking techniques, which was simulated the composition of natural extracellular matrix to repair osteochondral defects. This novel bilayer osteochondral graft had a seamlessly integrated layer structure, suitable pore size, high levels of porosity, and excellent mechanical properties. In vitro cell experiments of the bilayer scaffold indicated that the scaffold could promote the proliferation and adhesion of human bone marrow mesenchymal stem cells. In vivo osteochondral defects and micro-CT experiment revealed that bilayer scaffolds showed complete closure of the defect. Histology confirmed collagen and glycosaminoglycans were deposited in the new matrix of hyaline cartilage and bone in the bilayer scaffold group. Therefore, the developed bionic bilayer scaffold enhanced the regeneration of hyaline cartilage through subchondral bone formation and lateral host-tissue integration. In conclusion, this bilayer scaffold based on HLC could be used as the desired strategy for osteochondral defects regeneration.

Similar content being viewed by others

References

Martin I, Miot S, Barbero A, et al. Osteochondral tissue engineering. J BioMech, 2007, 40: 750–765

Wu Y, Zhu S, Wu C, et al. A bi-lineage conducive scaffold for osteochondral defect regeneration. Adv Funct Mater, 2014, 24: 4473–4483

Yuan X L, Meng H Y, Wang Y C, et al. Bone-cartilage interface crosstalk in osteoarthritis: potential pathways and future therapeutic strategies. Osteoarthritis Cartilage, 2014, 22: 1077–1089

Zhang Y, Yu J, Ren K, et al. Thermosensitive hydrogels as scaffolds for cartilage tissue rngineering. Biomacromolecules, 2019, 20: 1478–1492

Huey D J, Hu J C, Athanasiou K A. Unlike bone, cartilage regeneration remains elusive. Science, 2012, 338: 917–921

Yan L P, Silva-Correia J, Oliveira M B, et al. Bilayered silk/silknanoCaP scaffolds for osteochondral tissue engineering: In vitro and in vivo assessment of biological performance. Acta Biomater, 2015, 12: 227–241

Kang H, Zeng Y, Varghese S. Functionally graded multilayer scaffolds for in vivo osteochondral tissue engineering. Acta Biomater, 2018, 78: 365–377

Xia D, Liu Y, Wang S, et al. In vitro and in vivo investigation on biodegradable Mg-Li-Ca alloys for bone implant application. Sci China Mater, 2019, 62: 256–272

Xu Q, Liang J, Xue H, et al. Novel injectable and self-setting composite materials for bone defect repair. Sci China Mater, 2020, 63: 876–887

Levingstone T J, Thompson E, Matsiko A, et al. Multi-layered collagen-based scaffolds for osteochondral defect repair in rabbits. Acta Biomater, 2016, 32: 149–160

Wakitani S, Goto T, Young R G, et al. Repair of large full-thickness articular cartilage defects with allograft articular chondrocytes embedded in a collagen gel. Tissue Eng, 1998, 4: 429–444

Lahm A, Kreuz P C, Oberst M, et al. Subchondral and trabecular bone remodeling in canine experimental osteoarthritis. Arch Orthop Trauma Surg, 2006, 126: 582–587

Mrosek E H, Lahm A, Erggelet C, et al. Subchondral bone trauma causes cartilage matrix degeneration: an immunohistochemical analysis in a canine model. Osteoarthritis Cartilage, 2006, 14: 171–178

O’Shea T M, Miao X. Bilayered scaffolds for osteochondral tissue engineering. Tissue Eng Part B-Rev, 2008, 14: 447–464

Oliveira J M, Rodrigues M T, Silva S S, et al. Novel hydroxyapatite/chitosan bilayered scaffold for osteochondral tissue-engineering applications: Scaffold design and its performance when seeded with goat bone marrow stromal cells. Biomaterials, 2006, 27: 6123–6137

Reyes R, Delgado A, Sánchez E, et al. Repair of an osteochondral defect by sustained delivery of BMP-2 or TGF²1 from a bilayered alginate-PLGA scaffold. J Tissue Eng Regen Med, 2012

Guo X, Park H, Liu G, et al. In vitro generation of an osteochondral construct using injectable hydrogel composites encapsulating rabbit marrow mesenchymal stem cells. Biomaterials, 2009, 30: 2741–2752

Kon E, Delcogliano M, Filardo G, et al. Novel nano-composite multilayered biomaterial for osteochondral regeneration. Am J Sports Med, 2011, 39: 1180–1190

Chen J, Chen H, Li P, et al. Simultaneous regeneration of articular cartilage and subchondral bone in vivo using MSCs induced by a spatially controlled gene delivery system in bilayered integrated scaffolds. Biomaterials, 2011, 32: 4793–4805

Moutos F T, Freed L E, Guilak F. A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage. Nat Mater, 2007, 6: 162–167

Yang P J, Temenoff J S. Engineering Orthopedic Tissue Interfaces. Tissue Eng Part B-Rev, 2009, 15: 127–141

Gomes S, Leonor I B, Mano J F, et al. Natural and genetically engineered proteins for tissue engineering. Prog Polym Sci, 2012, 37: 1–17

Huang X, Jia J, Wang Z, et al. A novel chitosan-based sponge coated with self-assembled thrombin/tannic acid multilayer films as a hemostatic dressing. Chin J Polym Sci, 2015, 33: 284–290

Geng C, Hu X, Yang G, et al. Mechanically reinforced chitosan/cellulose nanocrystals composites with good transparency and biocompatibility. Chin J Polym Sci, 2015, 33: 61–69

Hu J, Cai X, Mo S, et al. Fabrication and characterization of chitosansilk fibroin/hydroxyapatite composites via in situ precipitation for bone tissue engineering. Chin J Polym Sci, 2015, 33: 1661–1671

Xu W K, Tang J Y, Yuan Z, et al. Accelerated cutaneous wound healing using an injectable teicoplanin-loaded PLGA-PEG-PLGA thermogel dressing. Chin J Polym Sci, 2019, 37: 548–559

Park S H, Song T, Bae T S, et al. Comparative analysis of collagens extracted from different animal sources for application of cartilage tissue engineering. Int J Precis Eng Manuf, 2012, 13: 2059–2066

Zhang L, Liu J, Zheng X, et al. Pullulan dialdehyde crosslinked gelatin hydrogels with high strength for biomedical applications. Carbohydrate Polyms, 2019, 216: 45–53

Ramshaw J A M. Biomedical applications of collagens. J Biomed Mater Res, 2016, 104: 665–675

Sionkowska A, Kozlowska J. Fish scales as a biocomposite of collagen and calcium salts. KEM, 2013, 587: 185–190

Fan D D, Luo Y, Mi Y, et al. Characteristics of fed-batch cultures of recombinant Escherichia coli containing human-like collagen cDNA at different specific growth rates. Biotechnol Lett, 2005, 27: 865–870

Zhang J, Ma X, Fan D, et al. Synthesis and characterization of hyaluronic acid/human-like collagen hydrogels. Mater Sci Eng-C, 2014, 43: 547–554

Li X, Xue W, Liu Y, et al. Novel multifunctional PB and PBH hydrogels as soft filler for tissue engineering. J Mater Chem B, 2015, 3: 4742–4755

Jiang X, Wang Y, Fan D, et al. A novel human-like collagen hemostatic sponge with uniform morphology, good biodegradability and biocompatibility. J Biomater Appl, 2017, 31: 1099–1107

Zhu C, Fan D, Wang Y. Human-like collagen/hyaluronic acid 3D scaffolds for vascular tissue engineering. Mater Sci Eng-C, 2014, 34: 393–401

Van Vlierberghe S, Dubruel P, Schacht E. Biopolymer-based hydrogels as scaffolds for tissue engineering applications: A review. Biomacromolecules, 2011, 12: 1387–1408

Yang J, Zhang Y S, Yue K, et al. Cell-laden hydrogels for osteochondral and cartilage tissue engineering. Acta Biomater, 2017, 57: 1–25

Matsiko A, Levingstone T J, O’Brien F J, et al. Addition of hyaluronic acid improves cellular infiltration and promotes early-stage chondrogenesis in a collagen-based scaffold for cartilage tissue engineering. J Mech Behav BioMed Mater, 2012, 11: 41–52

Yang Q, Peng J, Guo Q, et al. A cartilage ECM-derived 3-D porous acellular matrix scaffold for in vivo cartilage tissue engineering with PKH26-labeled chondrogenic bone marrow-derived mesenchymal stem cells. Biomaterials, 2008, 29: 2378–2387

Zheng X F, Lu S B, Zhang W G, et al. Mesenchymal stem cells on a decellularized cartilage matrix for cartilage tissue engineering. Biotechnol Bioproc E, 2011, 16: 593–602

Zheng X, Yang F, Wang S, et al. Fabrication and cell affinity of biomimetic structured PLGA/articular cartilage ECM composite scaffold. J Mater Sci-Mater Med, 2011, 22: 693–704

Yang F, Qu X, Cui W, et al. Manufacturing and morphology structure of polylactide-type microtubules orientation-structured scaffolds. Biomaterials, 2006, 27: 4923–4933

Harley B A, Lynn A K, Wissner-Gross Z, et al. Design of a multiphase osteochondral scaffold III: Fabrication of layered scaffolds with continuous interfaces. J Biomed Mater Res, 2009, 9999A: NA

McNamara S L, Rnjak-Kovacina J, Schmidt D F, et al. Silk as a biocohesive sacrificial binder in the fabrication of hydroxyapatite load bearing scaffolds. Biomaterials, 2014, 35: 6941–6953

Lu S, Lam J, Trachtenberg J E, et al. Dual growth factor delivery from bilayered, biodegradable hydrogel composites for spatially-guided osteochondral tissue repair. Biomaterials, 2014, 35: 8829–8839

Radhakrishnan J, Manigandan A, Chinnaswamy P, et al. Gradient nano-engineered in situ forming composite hydrogel for osteochondral regeneration. Biomaterials, 2018, 162: 82–98

Sophia Fox A J, Bedi A, Rodeo S A. The basic science of articular cartilage: Structure, composition, and function. Sports Health, 2009, 1: 461–468

Zhang Q, Lu H, Kawazoe N, et al. Pore size effect of collagen scaffolds on cartilage regeneration. Acta Biomater, 2014, 10: 2005–2013

Huang J, Xia X, Zou Q, et al. The long-term behaviors and differences in bone reconstruction of three polymer-based scaffolds with different degradability. J Mater Chem B, 2019, 7: 7690–7703

Ribeiro V P, Pina S, Costa J B, et al. Enzymatically cross-linked silk fibroin-based hierarchical scaffolds for osteochondral regeneration. ACS Appl Mater Interfaces, 2019, 11: 3781–3799

Drury J L, Mooney D J. Hydrogels for tissue engineering: Scaffold design variables and applications. Biomaterials, 2003, 24: 4337–4351

Madry H, van Dijk C N, Mueller-Gerbl M. The basic science of the subchondral bone. Knee Surg Sports Traumatol Arthrosc, 2010, 18: 419–433

Song X, Zhu C, Fan D, et al. A novel human-like collagen hydrogel scaffold with porous structure and sponge-like properties. Polymers, 2017, 9: 638

Naseri N, Poirier J M, Girandon L, et al. 3-Dimensional porous nanocomposite scaffolds based on cellulose nanofibers for cartilage tissue engineering: Tailoring of porosity and mechanical performance. RSC Adv, 2016, 6: 5999–6007

Wu X, Liu Y, Li X, et al. Preparation of aligned porous gelatin scaffolds by unidirectional freeze-drying method. Acta Biomater, 2010, 6: 1167–1177

Murphy C M, Schindeler A, Gleeson J P, et al. A collagen-hydroxyapatite scaffold allows for binding and co-delivery of recombinant bone morphogenetic proteins and bisphosphonates. Acta Biomater, 2014, 10: 2250–2258

Gleeson J P, Plunkett N A, O’Brien F J. Addition of hydroxyapatite improves stiffness, interconnectivity and osteogenic potential of a highly porous collagen-based scaffold for bone tissue regeneration. eCM, 2010, 20: 218–230

Vines J B, Lim D J, Anderson J M, et al. Hydroxyapatite nanoparticle reinforced peptide amphiphile nanomatrix enhances the osteogenic differentiation of mesenchymal stem cells by compositional ratios. Acta Biomater, 2012, 8: 4053–4063

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2019YFA0905200), National Natural Science Foundation of China (Grant Nos. 21838009, 21878247, and 21676214) and the Shaanxi Key Laboratory of Degradable Biomedical Materials Program (Grant No. 17JS124).

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Liu, K., Liu, Y., Duan, Z. et al. A biomimetic bi-layered tissue engineering scaffolds for osteochondral defects repair. Sci. China Technol. Sci. 64, 793–805 (2021). https://doi.org/10.1007/s11431-020-1597-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1597-4