Abstract

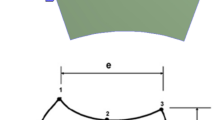

Tooth profile shift will change the thickness of gear teeth and a part of geometrical parameters of a gear pair, thus influencing its mesh stiffness and consequently the dynamic performances. In this paper, an analytical mesh stiffness calculation model for an internal gear pair in mesh considering the tooth profile shift is developed based on the potential energy principle. Geometrical representations of the tooth profile shift are firstly derived, and then fitted into the analytical tooth stiffness model of gears. This model could supply a convenient way for mesh stiffness calculation of profile shifted spur gears. Then, simulation studies are conducted based on the developed model to demonstrate the effects of tooth profile shift coefficient on the tooth compliances and the mesh stiffness of the internal spur gear pair. The results show that tooth profile shift has an obvious influence on the mean value, amplitude variation and phase of the mesh stiffness, from which it can be predicted that the dynamic response of an internal gear transmission system will be affected by the tooth profile shift.

Similar content being viewed by others

References

Hidaka T, Terauchi Y, Ishioka K. Dynamic behavior of planetary gear-2nd report: displacement of sun gear and ring gear. Bull JSME, 1976, 19: 1563–1570

Hidaka T, Terauchi Y, Nohara M, et al. Dynamic behavior of planetary gear-3rd report: displacement of ring gear in direction of line of action. Bull JSME, 1977, 20: 1663–1672

Karas F. Elastische Formänderung und Lastverteilung beim Doppeleingriff gerader Stirnradzähne. V.D.I. Forschh. 1941, 406: 1–17

Chen Z G, Shao Y M. Dynamic simulation of planetary gear with tooth root crack in ring gear. Eng Fail Anal, 2013, 31: 8–18

Chen Z G, Shao Y M. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth. Eng Fail Anal, 2011, 18: 2149–2164

Chen Z G, Shao Y M. Mesh stiffness of an internal spur gear pair with ring gear rim deformation. Mech Mach Theory, 2013, 69: 1–12

Chen Z G, Shao Y M, Su D Z. Dynamic simulation of planetary gear set with flexible spur ring gear. J Sound Vib, 2013, 332: 7191–7204

Satoshi O D A, Miyachika K. Root stress of thin-rimmed internal spur gear supported with pins. JSME Int J, 1987, 30: 646–652

Kahraman A, Kharazi A A, Umrani M. A deformable body dynamic analysis of planetary gears with thin rims. J Sound Vib, 2003, 262: 752–768

Kahraman A. Load sharing characteristics of planetary transmissions. Mech Mach Theory, 1994, 29: 1151–1165

Singh A. Load sharing behavior in epicyclic gears: physical explanation and generalized formulation. Mech Mach Theory, 2010, 45: 511–530

Singh A. Application of a system level model to study the planetary load sharing behavior. ASME J Mech Design, 2005, 127: 469–476

Sun T, Hu H. Nonlinear dynamics of a planetary gear system with multiple clearances. Mech Mach Theory, 2003, 38: 1371–1390

Lin J, Parker R G. Analytical characterization of the unique properties of planetary gear free vibration. T ASME J Vib Acoust, 1999, 121: 316–321

Lei Y G, Lin J, Zuo M J, et al. Condition monitoring and fault diagnosis of planetary gearboxes: A review. Measurement, 2014, 48: 292–305

Chaari F, Fakhfakh T, Haddar M. Analytical modelling of spur gear tooth crack and influence on gearmesh stiffness. Eur J Mech A-Solids, 2009, 28: 461–468

Weber C. The deformation of loaded gears and the effect on their load carrying capacity. Sponsored research, British Department of Science and Industrial Research, London, 1949

Cornell R W. Compliance and stress sensitivity of spur gear teeth. ASME J Mech Design, 1981, 103: 447–459

O’Donnell W J. Stress and deflection of built-in beams. ASME Paper No. 62-WA-16, 1974

Omar F K, Moustafa K A F, Emam S. Mathematical modeling of gearbox including defects with experimental verification. J Vib Control, 2011, 18: 1310–1321

Yang D C H, Lin J Y. Hertzian damping, tooth friction and bending elasticity in gear impact dynamics. J Mech T Auto Design, 1987, 109: 189–196

Tian X. Dynamic Simulation for system response of gearbox including localized gear faults. Dissertation of Master Degree. Alberta: University of Alberta, Edmonton, 2004

Tian X, Zuo M J, Fyfe K R. Analysis of the vibration response of a gearbox with gear tooth faults. In: The 2004 ASME International Mechanical Engineering Congress and Exposition, Anaheim, California USA, 2004: 785–793

Wu S, Zuo M J, Parey A. Simulation of spur gear dynamics and estimation of fault growth. J Sound Vib, 2008, 317: 608–624

Mohammed O D, Rantatalo M, Aidanpää J. Improving mesh stiffness calculation of cracked gears for the purpose of vibration-based fault analysis. Eng Fail Anal, 2013, 34: 235–251

Liang X H, Zuo M J, Patel T H. Evaluating the time-varying mesh stiffness of a planetary gear set using the potential energy method. P I Mech Eng C-J Mec, 2014, 228: 535–547

Liang X H, Zuo M J, Pandey M. Analytically evaluating the influence of crack on the mesh stiffness of a planetary gear set. Mech Mach Theory, 2014, 76: 2014

Chen Z G, Shao Y M. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack. Mech Mach Theory, 2013, 62: 63–74

Wang Q, Hu P, Zhang Y, et al. A model to determine mesh characteristics in a gear pair with tooth profile error. Adv Mech Eng, 2014: 1–10

AGMA 913-A98. Method for specifying the geometry of spur and helical gears, 1998

Mirica R F, Dobre G. On the distribution of the profile shift coefficients between mating gears in the case of cylindrical gear. In: 12th IFToMM World Congress, Besançon, 2007

Hu Y M, Shao Y M, Chen Z G, et al. Transient meshing performance of gears with different modification coefficients and helical angles using explicit dynamic FEA. Mech Syst Signal Pr, 2011, 25: 1786–1802

ISO/TR 4467, Addendum modification of the teeth of cylindrical gears for speed-reducing and speed-increasing gear pairs, 1982

DIN 3992, Profilverschiebung bei Stirnrädern mit Aussenverzahnung, 1964

Ristivojevic M, Lazovic T, Vencl A. Studying the load carrying capacity of spur gear tooth flanks. Mech Mach Theory, 2013, 59: 125–137

Marimuthu P, Muthuveerappan G. Optimum profile shift estimation on direct design asymmetric normal and high contact ratio spur gears based on load sharing. Procedia Engineering, 2014, 86: 709–717

Abderazek H, Ferhat D, Atanasovska I, et al. A differential evolution algorithm for tooth profile optimization with respect to balancing specific sliding coefficients of involute cylindrical spur and helical gears. Adv Mech Eng, 2015, 7: 1–11

Rajesh A R, Gonsalvis J, Venugopal K A. Load sharing analysis of bending strength in altered tooth-sum gears operating between a standard center distance and module. Eur J Eng Tech, 2015, 3: 50–61

Shiau T N, Chang J R, Huang K H, et al. Nonlinear dynamic analysis of a multi-gear train with time-varying mesh stiffness including modification coefficient effect. In: Proceedings of ASME Turbo Expo 2011, June 6-10, 2011, Vancouver, British Columbia, Canada

Ma H, Pang X, Feng R, et al. Evaluation of optimum profile modification curves of profile shifted spur gears based on vibration responses. Mech Syst Signal Pr, 2016, 70-71: 1131–1149

Ma H, Feng R, Pang X, et al. Effects of tooth crack on vibration responses of a profile shifted gear rotor system. J Mech Sci Tech, 2015, 29: 4093–4104

Lebold M, McClintic K, Campbell R, et al. Review of vibration analysis methods for gearbox diagnostics and prognostics. In: Proceedings of the 54th meeting of the society for machinery failure prevention technology, Virginia Beach, VA, 2000. 623–634

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Zhai, W., Shao, Y. et al. Mesh stiffness evaluation of an internal spur gear pair with tooth profile shift. Sci. China Technol. Sci. 59, 1328–1339 (2016). https://doi.org/10.1007/s11431-016-6090-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-6090-6