Abstract

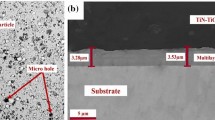

The TiN, TiAlN and TiAlSiN coatings were deposited on H13 hot-worked mold steel by cathodic arc ion plating (CAIP). The morphologies, phase compositions, and nanoindentation parameters, such as creep hardness, elastic modulus and plastic deformation energy of the coatings were analyzed with field emission scanning electron microscopy (FESEM), X-ray diffraction (XRD) and nanoindentation testing, respectively, and the test results were compared with equation describing the indentation model. The results show that the TiN, TiAlN and TiAlSiN coating surfaces were dense and composed of TiN, TiN + TiAlN, TiN + Si3N4 + TiAlN phases, respectively. There was no spalling or cracking on the indentation surface. The creep hardness of the TiN, TiAlN and TiAlSiN coatings was 7.33, 13.5, and 15.2 GPa, respectively; the corresponding hardness measured by nanoindentation was 7.09, 15.6, and 21.7 GPa, respectively; and the corresponding elastic modulus was 201.93, 172.79, and 162.77 GPa, respectively. The contact depth and elastic modulus calculated by the indentation model were close to those of the test results, but the remaining indentation parameters showed discrepancies. The sequence of plastic deformation energy was TiN > TiAlN>TiAlSiN.

Similar content being viewed by others

References

Song W W, Min Y G, Wu X C. Study on carbides and their evolution in H13 hot work steel. Trans Mater Heat Treat, 2009, 30: 122–126

Zhang H, Xu X G, Fei X Y, et al. Effect of CrTiAlN coatings on oxidation behaviour of H13 steel at 800°C and 900°C. J Synth Cryst, 2013, 42: 2715–271

Alan X, Christian B, David E J A, et al. Ion-irradiation-induced clustering in W-Re and W-Re-Os alloys: A comparative study using atom probe tomography and nanoindentation measurements. Acta Mater, 2015, 87: 121–127

He Z H, Qian C X, Zhang Y, et al. Nanoindentation characteristics ofcement with different mineral admixtures. Sci China Tech Sci, 2013, 56: 1119–1123

Xu Y C, Chen K H, Wang S Q, et al. Oxidation and cutting properties of TiN and TiAlN coated cemeted carbide. Mater Eng Powder Metall, 2011, 16: 425–430

Chang Y Y, Yang S M. High temperature oxidation of multicomponent TiAlSiN coating. Thin Solid Film, 2010, 518: 34–37

Xie Z W, Wang L P, Wang X F, et al. Influence of oxidation on the structural and mechanical properties of TiAlSiN coatings synthesized by multi-plasma immersion ion implantation and deposition. Nucl Instrum Meth B, 271: 1–5

Liang J J, Wei H, Hou G C, et al. Progress in mechanical and physical properties of high-temperature coating materials. Rare Met Mater Eng, 2008, 37: 1134–1138

He Z H, Qian C X, Zhang Y, et al. Nanoindentation characteristics ofcement with different mineral admixtures. Sci China Tech Sci, 2013, 56: 1119–1123

Francisco G F, Emanuele B, Angelica C, et al. The mechanical properties of a nanocrystalline Al2O3/a-Al2O3 composite coating measured by nanoindentation and Brillouin spectroscopy. Acta Mater, 2013, 61: 2662–2670

Han J D, Pan G H, SUN W, et al. Application of nanoindentation toinvestigate chemomechanical properties change of cement paste in the carbonation reaction. Sci China Tech Sci, 2012, 55: 616–622

Dipen Y, Patel K, Hamad F, et al. Extracting single-crystal elastic constants from polycrystalline samples using spherical nanoindentation and orientation measurements. Acta Mater, 2014, 79: 108–116

Liu T W, Xian X B, Wu S, et al. Properties of TiN films on uranium surface by arc ion plating under different bias voltages. Rare Met Mater Eng, 2006, 35: 1437–1440

Liang J C, Zhou W P, Zhang F G, et al. Influence of target on microstructure and mechanical behavior TiAlN coatings. Chin J Vac Sci Tech, 2014, 34: 714–719

Yu D H, Wang C Y, Cheng X L, et al. Microstructure and properties of TiAlSiN coatings prepared by hybrid PVD technology. Thin Solid Films, 2009, 517: 4950–4955

Ji F, Xue S B, Liu S, et al. Measurement of creep stress exponent of Zn-Al filler metal at room temperature by using nanoindentation. Trans China Weld Inst, 2013, 34: 75–79

Recco A A C, Viafara C C, Sinatora A, et al. Energy dissipation in depth-sensing indentation as a characteristic of the nanoscratch behaviour of coatings. Wear, 2009, 267: 1146–1152

Wang F J, Qian Y Y, Ma X. Measurement of mechanical properties of Sn-Ag-Cu bulk solder BGA solder joint using nanoindentation. Acta Sinica, 2005, 41: 775–779

Peng J, Long Z L, Wei H Q, et al. Creep behavior of a Fe-based bulk amorphous alloy using nanoindentation. Acta Phys Sinica, 2009, 58: 4059–4065

Oliver W C, Pharr G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiment. J Mater Res, 1992, 7: 1564–1583

Yetna M N, Chicot D, Ndjaka J. M, et al. A criterion to identify sinking-in and piling-up indentation of materials. Int J Mech Sci, 2015, 90: 145–150

Han C F, Lin J. Modeling to evaluate the contact areas of hard materials during the nano-indentatio en-Finn tests. Sensor Actuat A-Phys, 2008, 147: 229–241

Kang S K, Kim Y C, Lee J W, et al. Effect of contact angle on contact morphology and Vickers hardness measurement in instrumented indentation testing. Int J Mech Sci, 2014, 85: 104–109

Ricardo D T, Paulo C S J, Cleomar S, et al. Influence of the nitriding and TiAlN/TiN coating thickness on the sliding wear behavior of duplex treated AISI H13 steel. Surf Coat Tech, 2010, 205: 1381–1385

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, D., Fu, G. Nanoindentation analysis of TiN, TiAlN, and TiAlSiN coatings prepared by cathode ion plating. Sci. China Technol. Sci. 58, 1360–1368 (2015). https://doi.org/10.1007/s11431-015-5876-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-015-5876-2