Abstract

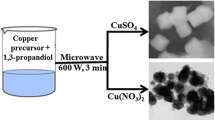

By stepwise adding of reducer N2H4·H2O, cuprous oxide (Cu2O) nanoparticles (NPs) with adjustable structures were synthesized. The features of Cu2O NPs were characterized by XRD, TEM and UV-Vis absorption spectra. When the reducer was added into the reactant system at one time, the sizes of the Cu2O NPs are in the range of 120–140 nm. Most Cu2O NPs are solid spheres. As the reducer was divided into two equal parts and stepwisely added, almost all the NPs are hollow spheres with good size (150–170 nm) distribution and dispersity. But when the reducer was divided into three or four equal parts and stepwisely added, the NPs are hollow spheres, core-shell structures or solid spheres, and the sizes distribution of the products is deteriorated. The effect of sodium hydrate (NaOH) was also probed. Addition of NaOH speeded up the nucleation and growth processes of Cu2O NPs. With the alkalinity increase, the shells of the hollow spheres become compact and the thicknesses of the shells increase, but the size distribution of the NPs is deteriorated. The absorption spectra of the Cu2O NPs are tunable. With the shell thicknesses increase, the absorption peaks have red shifts. An inside-outside growth model of Cu2O NPs was proposed to explain the results. The Cu2O single crystalline grains grow not only in the reactant solution, but also inside of the hollow nanospheres. The new Cu2O nanocrystallines can not only aggregate onto the shells of the nano hollow spheres, but also inside and outside of the hollow spheres, which leads to increasing the shell thicknesses of the hollow spheres, forming core-shell structures or small solid spheres of Cu2O NPs, respectively.

Similar content being viewed by others

References

Chen Y H, Han H, Fang F Z, et al. MD simulation of nanometric cutting of copper with and without water lubrication. Sci China Tech Sci, 2014, 57: 1154–1159

Yang Q, Liang S H, Wang J, et al. Morphologies and corrosion resistances of electroless Ni-P coated nanoporous coppers. Sci China Tech Sci, 2013, 56: 1147–1150

Zhao X H, Fuji M, Shirai T, et al. Electrocatalytic evolution of oxygen on NiCu particles modifying conductive alumina/nano-carbon network composite electrode. Sci China Tech Sci, 2012, 55: 3388–3394

He J L, Luo F C, Hu J, et al. Cu segregation and its effects on the electrical properties of calcium copper titanate. Sci China Tech Sci, 2011, 54: 2506–2510

Chen M J, Xiao G B, Chen J X, et al. Research on the influence of machining introduced sub-surface defects and residue stress upon the mechanical properties of single crystal copper. Sci China Tech Sci, 2010, 53: 3161–3167

Chen L C. Review of preparation and optoelectronic characteristics of Cu2O-based solar cells with nanostructure. Mater Sci Semicon Proc, 2013, 16: 1172–1185

Liu D Q, Yang Z B, Wang P, et al. Preparation of 3D nanoporous copper-supported cuprous oxide for high-performance lithium ion battery anodes. Nanoscale, 2013, 5: 1917–1921

Paolella A, Brescia R, Prato M, et al. Colloidal synthesis of cuprite (Cu2O) octahedral nanocrystals and their electrochemical lithiation. ACS Appl Mater Interfaces, 2013, 5: 2745–2751

Jiang T F, Xie T F, Yang W S, et al. Photoelectrochemical and photovoltaic properties of p.n Cu2O homojunction films and their photocatalytic performance. J Phys Chem C, 2013, 117: 4619–4624

Zhang Z, Zhong C, Deng Y D, et al. The manufacture of porous cuprous oxide film with photocatalytic properties via an electrochemical-chemical combination method. RSC Adv, 2013, 3: 6763–6766

Liu G G, He F, Li X Q, et al. Three-dimensional cuprous oxide microtube lattices with high catalytic activity templated by bacterial cellulose nanofibers. J Mater Chem, 2011, 21: 10637–10640

Pang H, Gao F, Lu Q Y. Glycine-assisted double-solvothermal approach for various cuprous oxide structures with good catalytic activities. Cryst Eng Commun, 2010, 12: 406–412

Yan X Y, Tong X L, Zhang Y F, et al. Cuprous oxide nanoparticles dispersed on reduced graphene oxide as an efficient electrocatalyst for oxygen reduction reaction. Chem Commun, 2012, 48: 1892–1894

Zhu H T, Wang J X, Xu G Y. Fast synthesis of Cu2O hollow microspheres and their application in DNA biosensor of hepatitis B virus. Cryst Growth Design, 2009, 9: 633–638

Meng F H, Shi W, Sun Y Y, et al. Nonenzym aticbiosensor based on CuxO nanoparticles deposited on polypyrrole nanowires for improving detection range. Biosen Bioelectr, 2013, 42: 141–147

Garjonyte R, Malinauskas A. Amperometric sensor for hydrogen peroxide, based on Cu2O or CuO modified carbon paste electrodes. Fresenius J Anal Chem, 1998, 360: 122–123

Guan L N, Pang H, Wang J J, et al. Fabrication of novel comb-like Cu2O nanorod-based structures through an interface etching method and their application as ethanol sensors. Chem Commun, 2010, 46: 7022–7024

Sui Y M, Fu W Y, Yang H B, et al. Low temperature synthesis of Cu2O crystals: Shape evolution and growth mechanism. Cryst Growth Design, 2010, 10: 99–108

Wang D B, Mo M S, Yu D B, et al. Large-scale growth and shape evolution of Cu2O cubes. Cryst Growth Design, 2003, 3: 717–720

Chang Y, Teo J J, Zeng H C. Formation of colloidal CuO nanocrystallites and their spherical aggregation and reductive transformation to hollow Cu2O nanospheres. Langmuir 2005, 21: 1074–1079

Zhang L, Wang H. Cuprous oxide nanoshells with geometrically tunable optical properties. ACS Nano, 2011, 5: 3257–3267

Xu H L, Wang W Z, Zhou L. A growth model of single crystalline hollow spheres: Oriented attachment of Cu2O nanoparticles to the single crystalline shell wall. Cryst Growth Design, 2008, 8: 3486–3489

Zhang N, Du Y L, Zhang Y. A simple method for controlling the type of cuprous oxide semiconductors using different surfactants. J Mater Chem, 2011, 21: 5408–5413

Enamul H, Chang M K, Sung H J. Facile synthesis of cuprous oxide using ultrasound, microwave and electric heating: Effect of heating methods on synthesis kinetics, morphology and yield. Cryst Eng Commun, 2011, 13: 4060–4068

Liu P S, Li Z G, Cai W P, et al. Fabrication of cuprous oxide nanoparticles by laser ablation in PVP aqueous solution. RSC Adv, 2011, 1: 847–851

Kuo C H, Huang M H. Morphologically controlled synthesis of Cu2O nanocrystals and their properties. Nano Today, 2010, 5: 106–116

Wang W C, Lyu L M, Huang M H. Investigation of the effects of polyhedral gold nanocrystal morphology and facets on the formation of Au-Cu2O core-shell heterostructures. Chem Mater, 2011, 23: 2677–2684

Kuo C H, Hua T E, Huang M H. Au nanocrystal-directed growth of Au-Cu2O core-shell heterostructures with precise morphological control. J Am Chem Soc, 2009, 131: 17871–17878

Zhang L, Jing H, Boisvert G, et al. Geometry control and optical tunability of metal-cuprous oxide core-shell nanoparticles. ACS Nano, 2012, 6: 3514–3527

Zhang L, Blom D A, Wang H. Au-Cu2O core-shell nanoparticles: A hybrid metal-semiconductor heteronanostructure with geometrically tunable optical properties. Chem Mater, 2011, 23: 4587–4598

Liu D Y, Ding S Y, Lin H X, et al. Distinctive enhanced and tunable plasmon resonant absorption from controllable Au@Cu2O nanoparticles: experimental and theoretical modeling. J Phys C, 2012, 116: 4477–4483

Li J T, Cushing S K, Bright J, et al. Ag@Cu2O core-shell nanoparticles as visible-light plasmonic photocatalysts. ACS Catal, 2013, 3: 47–51

Kuo C H, Chu Y T, Song Y F, et al. Cu2O nanocrystal-templated growth of Cu2S nanocages with encapsulated Au nanoparticles and in-situ transmission X-ray microscopy study. Adv Funct Mater, 2011, 21: 792–797

Zhu H T, Wang J X, Wu D X. Fast synthesis, formation mechanism, and control of shell thickness of CuS hollow spheres. Inorg Chem, 2009, 48: 7099–7104

Yec C C, Zeng H C. Synthetic architecture of multiple core-shell and yolk-shell structures of (Cu2O@)n Cu2O(n=1-4) with centricity and eccentricity. Chem Mater, 2012, 24: 1917–1929

Xiao J R, Li Y W, Jiang A H. Structure, optical property and thermal stablity of copper nitride films prepared by reactive radio frequency magnetron sputtering. J Mater Sci Tech, 2011, 27: 403–407

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, A., Wang, Y., Li, S. et al. Stepwise synthesis of cuprous oxide nanoparticles with adjustable structures and growth model. Sci. China Technol. Sci. 57, 2287–2294 (2014). https://doi.org/10.1007/s11431-014-5658-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5658-2