Abstract

Agarwood has been valued as an exquisite, high-grade fragrant wood since ancient times. Due to the scarcity of high-quality agarwood, it is quite expensive, and the number of original plants has been drastically reduced due to overharvesting, including illegal logging. Despite this, a reliable method of agarwood cultivation has yet to be developed. Thus, identifying the biosynthetic pathways of the fragrant components in agarwood might help developers to optimize the culture conditions and create artificial agarwood, by monitoring the expression of the biosynthetic enzymes or their genes. This review presents the characteristics of our recently identified key enzyme, 2-(2-phenylethyl)chromone precursor synthase (PECPS), which generates the common precursor of 2-(2-phenylethyl)chromones (PECs), the main fragrances in agarwood, as well as our reasoning to reach these conclusions. We also discuss the biosynthetic pathway of PECs, unveiled following the identification of PECPS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Agarwood, also known as aloeswood, gaharu, eaglewood, jinkoh and chenxiang, is a highly prized, expensive wood. For centuries, it has been used in China, Japan, and other countries as an exquisitely fragrant wood [1,2,3,4]. Agarwood is also quite popular in Japan, where it is used as incense in traditional ceremonies. Agarwood is valued not only as a fragrance but also as a digestive, analgesic, and antiemetic agent to treat abdominal pain, vomiting, and insomnia, in a wide range of Asian countries [2]. The original agarwood plants are Aquilaria sinensis, A. malaccensis, and A. agallocha, which belong to the family Thymelaeaceae, and the heartwood of their wood or root is used as agarwood. The principal components of agarwood are 2-(2-phenylethyl)chromones (PECs) [5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22]. The PEC monomers are structurally classified into three types, flindersiachromones (FDC), oxidoagarochromones (OAC), and agarotetrolchromones (ATC), and these monomers, as well as their dimers and trimers, and the hybrid types combined with sesquiterpenes, have been identified as the aromatic components of agarwood (Fig. 1). The exquisite fragrance of agarwood is thought to be produced by the synergistic effects of these slightly different fragrances and sesquiterpenes, which are the essential oil components. Recently, PECs have also attracted attention from a pharmaceutical perspective due to their physiological activities, including neuroprotective, acetylcholinesterase inhibitory, anti-inflammatory, and antibacterial effects [23,24,25,26,27,28,29,30,31]. However, these PECs are grouped in compounds that accumulate within resin at parts of the wood damaged by prolonged pathological stress, such as bacterial infection and insect infestation. In other words, the original plants on the verge of death are considered to be agarwood, and thus only a few percent can be used. As a side note, the name “agarwood” is derived from the fact that the wood becomes submerged in water due to its increased specific gravity by the deposition of resin.

To produce agarwood artificially, various efforts such as artificially stressing the original plant have been attempted in some countries, including Thailand, Vietnam, and Myanmar, but in spite of the cost and labor involved, such products are generally of inferior quality and not always successfully recognized as agarwood. Although the authors have not directly seen the method, artificial agarwood is cultivated by hammering nails into the trunks of ~ 10-year old original trees, drilling holes in them, and inoculating specific bacteria into the drilled holes, which then stimulate resin production [32,33,34,35,36]. Furthermore, attempts to produce the most expensive type of agarwood, which can be traded at prices higher than the same weight of gold and requires the accumulation of resin over many years, have been unsuccessful so far. Due to the rarity of agarwood, the market price is always extravagant. Therefore, illegal logging has persisted and the number of original plants has been dramatically reduced. Accordingly, the authors have been conducting research on the biosynthesis of agarwood PECs, to develop a new methodology for the cultivation of high quality, artificial agarwood.

In this paper, we review the recent advances in biosynthetic studies of PECs in agarwood, obtained during the course of our research. We demonstrate that PECs are biosynthesized from a common precursor with a C6–C5–C6 skeleton produced by 2-(2-phenylethyl)chromone precursor synthase (PECPS), a type III polyketide synthase (PKS), which is mechanistically distinct from other previously reported type III PKSs.

Identification of the gene encoding the enzyme involved in the 2-(2-phenylethyl)chromone scaffold biosynthesis

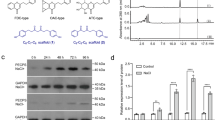

Most candidate genes responsible for the biosynthesis of natural compounds in plants have been identified by investigating the enzyme genes expressed in response to the accumulation of the target natural organic compounds, and then analyzing the functions of the candidate genes. This general methodology was also used in this study. However, to experimentally predict the biosynthetic genes using this method, the efficient analysis of the gene expression linked to the accumulation of compounds is required. Therefore, using plants as the target of this study is not feasible, due to their slow growth rate. To this end, Professor Shi (one of the authors of this review) and his group first created A. sinensis calli that successfully produced PECs (1‒13), especially the FDC-type, under salt stress conditions (Fig. 2) [37]. The key enzymes involved in PECs biosynthesis were predicted to be type III PKSs, since the structures of PECs are similar to those of flavonoids such as apigenin. In addition, chalcone, the common flavonoid biosynthetic precursor with a C6–C3–C6 skeleton, is biosynthesized by chalcone synthase (CHS), a type III PKS family member (Fig. 3a) [38,39,40].

Formation of polyketides by type III PKSs. a‒f Proposed synthetic mechanisms of a naringenin chalcone by CHS including AsCHS, b bisnoryangonin and p-coumaroyltriacetic acid lactone by AsPKS1 and AsPKS2, c 5,7-dihydroxy-2-methylchromone by PCS, d tetrahydrobisdemethoxycurcumin by the CUS Met265Val and Gly274Phe mutants and PECPS, e 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione by PECPS, and f bisdemethoxycurcumin by CUS

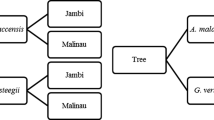

Investigations of the type III PKS genes in the calli suggested that the expression of genes encoding four type III PKSs (PECPS, AsPKS1, AsPKS2, and AsCHS) was upregulated in response to the accumulation of the aforementioned PECs [41, 42]. Their amino acid sequences revealed the conservation of the catalytic triad, cysteine (Cys), histidine (His), and asparagine (Asn), which is crucial for the condensation reaction by type III PKSs (Fig. 4) [38,39,40, 43]. A phylogenetic tree analysis demonstrated that AsCHS belongs to the same subgroup as CHS, whereas PECPS, AsPKS1, and AsPKS2 belong to different subgroups, and thus one of the PECPS, AsPKS1, and AsPKS2 enzymes, or a combination, may be involved in the formation of the PECs scaffold [41, 42].

Comparisons of amino acid sequences of A. sinensis PKSs and other type III PKSs. The Cys, His, and Asn catalytic triad residues are colored green. The residues forming the Ser351-Asn142-H2O-Tyr207-Glu202 rearrangement in CUS and the corresponding residues in other type III PKSs are highlighted in blue. GenBank accession numbers are as follows: PECPS, MH885494; AsPKS1, MW380862; AsPKS2, MW380863; AsCHS, EF103197; MsCHS (Medicago sativa CHS2), L02902; OsCUS, BAC79571. PECPS shares 39%, 37%, 65%, 60%, and 47% amino acid identities with AsPKS1, AsPKS2, AsCHS, MsCHS, and OsCUS, respectively

To further clarify each enzyme function, AsCHS, belonging to the CHS family in the phylogenetic tree, and AsPKS1 and AsPKS2, which are located furthest away from CHS in the phylogenetic tree, were expressed in Escherichia coli, and their enzymatic reaction products derived from p-coumaroyl-CoA and malonyl-CoA were investigated [41, 42]. As expected, AsCHS produced naringenin chalcone from the condensations of three malonyl-CoAs with p-coumaroyl-CoA via Claisen-type cyclization, confirming its function as a CHS (Fig. 3a). In contrast, both AsPKS1 and AsPKS2 produced α-pyrones, bisnoryangonin and p-coumaroyltriacetic acid lactone, derived from two and three malonyl-CoAs with p-coumaroyl-CoA via lactonization, respectively (Fig. 3b), which are known as byproducts of the in vitro CHS reactions [40]. The structures of α-pyrones are unlikely to be components of the PEC scaffold. Therefore, these results strongly suggested that PECPS might be the target type III PKS involved in the biosynthesis of the PEC scaffold. However, it was difficult to predict its functions solely from the amino acid sequence.

Functional analysis of PECPS

Considering the structures of PECs, their scaffolds may be biosynthesized from the condensations of four malonyl-CoAs with 4-hydroxyphenylpropionyl-CoA via the formation of a chromone ring, in a manner similar to that of pentaketide chromone synthase (PCS) from Aloe arborescens (Fig. 3c and Supplementary Fig. S1) [44, 45]. Thus, PECPS was heterologously expressed in E. coli and the products derived from two CoA-thioester substrates, 4-hydroxyphenylpropionyl-CoA and malonyl-CoA, were investigated in the presence of purified recombinant PECPS. Unexpectedly, PECPS produced tetrahydrobisdemethoxycurcumin, which was previously reported as a diarylheptanoid generated from two 4-hydroxyphenylpropionyl-CoAs and one malonyl-CoA by the curcuminoid synthase (CUS) Met265Val and Gly274Phe mutants [46] (Fig. 3d). In light of this result, 4-hydroxyphenylpropionyl-CoA, malonyl-CoA, and benzoyl-CoA are regarded as the possible substrates of PECPS, which lead to the formation of the C6–C5–C6 precursor of the PEC scaffold (Fig. 3e and Supplementary Fig. S2). Furthermore, salicyloyl-CoA may also be a possible alternative substrate in place of benzoyl-CoA, and would directly lead to the formation of a chromone corresponding to the PEC scaffold (Supplementary Fig. S3). In nature, curcumin in Curcuma longa and alkyl quinolines in Evodia rutaecarpa were reportedly biosynthesized from two feruloyl-CoAs and one malonyl-CoA, and from one N-methylanthraniloyl-CoA, one malonyl-CoA, and one fatty acyl-CoA, respectively, by the collaboration of two functionally distinct type III PKSs [47,48,49]. Furthermore, although the in vivo function is still unclear, the cus gene has also been identified in the genome of the rice Oryza sativa, and an in vitro functional analysis revealed that this enzyme is capable of performing the one-pot synthesis of bisdemethoxycurcumin, by catalyzing the condensation of a malonyl-CoA with p-coumaroyl-CoA, followed by the condensation of the resulting p-coumaroyl-β-diketide acid with a second p-coumaroyl-CoA (Fig. 3f) [46, 50]. Thus, it would not be surprising that with PECPS alone, the PEC scaffold could be generated from three substrates: 4-hydroxyphenylpropionyl-CoA, malonyl-CoA, and benzoyl-CoA. Although not mentioned in our first publication on PECPS [42], we have also confirmed that AsCHS, AsPKS1, and AsPKS2 are unable to produce tetrahydrobisdemethoxycurcumin from 4-hydroxyphenylpropionyl-CoA and malonyl-CoA. Guided by this information, we subjected PECPS to an enzyme reaction using 4-hydroxyphenylpropionyl-CoA, malonyl-CoA, and benzoyl-CoA as substrates, and found that PECPS indeed produces a diarylpentanoid, 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione, which corresponds to the precursor of the PEC scaffold (Fig. 3e and Supplementary Fig. S2) [42]. In contrast, when salicyloyl-CoA was provided instead of benzoyl-CoA, PECPS no longer produced the diarylpentanoid and the chromones corresponding to the PEC scaffold. These observations strongly suggested that PECPS is a type III PKS that biosynthesizes a linear diarylpentanoid, which would presumably be converted to the chromone form by other enzyme(s) in A. sinensis.

To further verify the in vivo biochemical PECPS function, we conducted two in vivo experiments, the transient expression of PECPS in the model plant, Nicotiana benthamiana, and the knockdown expression of PECPS in A. sinensis calli, since the observed enzyme activity of PECPS may be limited in the in vitro enzymatic reactions [42]. The transient expression of PECPS in N. benthamiana revealed that 5-hydroxy-1,7-bis(4-hydroxyphenyl)heptan-3-one, a diarylheptanoid, only accumulated in leaves expressing the pecps gene (Fig. 5). 5-Hydroxy-1,7-bis(4-hydroxyphenyl)heptan-3-one is a tetrahydrobisdemethoxycurcumin derivative with a reduced double bond, suggesting that PECPS produces tetrahydrobisdemethoxycurcumin, and then an oxidoreductase(s) or other enzyme(s) in N. benthamiana presumably converts it to 5-hydroxy-1,7-bis(4-hydroxyphenyl)heptan-3-one. Furthermore, we found that the PECPS in expressed N. benthamiana leaves conferred the ability to produce 2-(4-hydroxyphenylethyl)-4H-chromen-4-one when benzoyl-CoA or 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione was provided in the culture medium (Fig. 5). These observations demonstrated that PECPS was able to produce 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione even in N. benthamiana leaves, and that the PECPS product was converted to 2-(4-hydroxyphenylethyl)-4H-chromen-4-one by hydroxylase(s) and/or reductase(s) that are originally present in the N. benthamiana leaves. In addition, an RNAi knockdown of PECPS expression in A. sinensis calli indicated that the production of PECs was dramatically reduced in calli that showed significantly downregulated expression of PECPS, although we were unable to completely knock out the pecps gene in the calli. These studies confirmed that PECPS is indeed a key biosynthetic enzyme that forms the C6–C5–C6 precursor of the PEC scaffold in A. sinensis, and that the PECs would be biosynthesized via the formation of a diarylpentanoid, 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione.

Catalytic mechanism of PECPS

PECPS was thus found to be a novel type III PKS that condenses 4-hydroxyphenylpropionyl-CoA, benzoyl-CoA, and malonyl-CoA to form the diarylpentanoid. From the structure of the product, PECPS is suggested to (1) accept either 4-hydroxyphenylpropionyl-CoA or benzoyl-CoA as the initial starter substrate with malonyl-CoA as the first extender substrate to produce the corresponding acyl-β-diketide-CoA intermediate, (2) hydrolyze the acyl-β-diketide-CoA to form the corresponding acyl-β-diketide acid intermediate as the second extender substrate, and (3) condense the acyl-β-diketide acid intermediate with benzoyl-CoA (when 4-hydroxyphenylpropionyl-CoA was first used) or 4-hydroxyphenylpropionyl-CoA (when benzoyl-CoA was first used), to generate a diarylpentanoid as the final product (Supplementary Fig. S2). However, the aforementioned results did not allow us to determine which substrate PECPS uses as the first starter substrate and whether PECPS is capable of catalyzing all reactions. To this end, we conducted additional experiments, including an isothermal titration calorimetry (ITC) analysis for the substrate binding affinity, LC–MS analysis for β-diketide-CoA and its acid formations, and a feeding experiment for the PECPS catalytic ability [42]. Notably, the ITC analysis demonstrated that the binding affinity of PECPS to 4-hydroxyphenylpropionyl-CoA (KD = 18.57 ± 1.37 μM) was significantly higher than that of benzoyl-CoA (KD value close to 1,000 μM). Furthermore, the LC–MS analysis revealed the appearances of 4-hydroxyphenylpropionyl-β-diketide-CoA and 4-hydroxyphenylpropionyl-β-diketide acid in the PECPS reaction products, without any evidence of the production of not only benzoyl-β-diketide-CoA but also benzoyl-β-diketide acid, suggesting that PECPS might use 4-hydroxyphenylpropionyl-CoA and malonyl-CoA to generate the corresponding β-diketide-CoA intermediate. The in vitro feeding experiment of 4-hydroxyphenylpropionyl-β-diketide-CoA in the presence and absence of PECPS indicated no differences in the amounts of 4-hydroxyphenylpropionyl-β-diketide acid produced by both reactions, suggesting that PECPS could not form the β-diketide acid intermediate from the 4-hydroxyphenylpropionyl-β-diketide-CoA intermediate.

It is remarkable that PECPS can catalyze the one-pot formation of the diarylpentanoid, despite its inability to cleave the thioester-bond of the β-diketide-CoA intermediate. We speculated that the detailed catalytic mechanism of PECPS also differs from that of CUS, which has been proposed to employ the hydrolysis reaction to generate the β-diketide acid, with a nucleophilic water molecule forming the hydrogen bond networks with the rearrangement of Ser351-Asn142-H2O-Tyr207-Glu202, neighboring the catalytic Cys at the active-site center, and to retain the β-diketide acid in the active-site pocket during the one-pot formation of the diarylheptanoid [46]. Thus, PECPS might also be a mechanistically new type III PKS that has never been observed previously, and this hypothesis was further verified from the X-ray crystal structure analysis of PECPS at 1.98 Å resolution, in combination with docking simulations of the substrates and putative intermediates [42].

Type III PKSs are homodimeric enzymes consisting only of keto synthase (KS) subunits, with molecular weights of about 40 kDa [38‒40, 43]. The crystal structure of PECPS showed the typical type III PKS fold, and no significant differences were observed in the overall structures [42]. However, the X-ray crystal structure revealed that PECPS lacks the pocket corresponding to the β-diketide acid intermediate-binding pocket in CUS [46], and instead, the active-site cavity of PECPS extends in a different direction from that of CUS (Fig. 6). The direction of the extended active-site cavity was similar to that of Medicago sativa CHS2 [51], but its depth was shallower. The observed active-site volume of the PECPS active-site cavity is thus apparently smaller than those of CUS and CHS, suggesting that it might be impossible for PECPS to accommodate the β-diketide acid intermediate with the second starter substrate in the active-site cavity as the second extender substrate. Furthermore, the docking studies suggested that the PECPS active-site cavity is large enough to accommodate the 4-hydroxyphenylpropionyl-β-diketide unit derived from the condensation of 4-hydroxyphenylpropionyl-CoA and malonyl-CoA (Figs. 6 and 7a‒c). However, it is not large enough to accept a benzoyl unit together with the 4-hydroxyphenylpropionyl-β-diketide unit, as expected (Fig. 7a‒c). In this docking simulation, the hydrogen bonding network containing the water molecule that might be responsible for the formation of a β-diketide acid intermediate like CUS was also absent in the PECPS active-site cavity. These results suggested that PECPS produces a diarylpentanoid by employing the following catalytic mechanism, which is completely different from that of CUS (Fig. 7d). (1) PECPS receives the 4-hydroxyphenylpropionyl unit of the initial starter substrate, 4-hydroxyphenylpropionyl-CoA, with the catalytic center Cys166, and then catalyzes the decarboxylative condensation of malonyl-CoA with the 4-hydroxyphenylpropionyl unit tethered to Cys166 to produce the 4-hydroxyphenylpropionyl-β-diketide-CoA intermediate. This is then released from the enzyme and hydrolyzed to 4-hydroxyphenylpropionyl-β-diketide acid. Subsequently, (2) PECPS receives the benzoyl unit of benzoyl-CoA with the catalytic center Cys166, and then condenses 4-hydroxyphenylpropionyl-β-diketide acid with the benzoyl unit, to generate 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione as the final C6–C5–C6 product.

Comparison of the active-site architectures of a PECPS, b CUS, and c Medicago sativa CHS2. The 4-hydroxyphenylpropionyl-β-diketide-CoA from the docking simulation is shown as a blue stick model in the PECPS active-site cavity. The naringenin molecule complexed with the M. sativa CHS2 crystal structure and the water molecule in the Ser351-Asn142-H2O-Tyr207 rearrangement in CUS are indicated with a blue stick model and a light-blue sphere, respectively. The entrances of the active-site cavities are indicated with black arrows. The catalytic triads are highlighted with black stick models. Protein Data Bank ID numbers are as follows: PECPS, 7FFA; CUS, 3ALE; M. sativa CHS2, 1CGK

Proposed mechanism for the formation of 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione by PECPS. Docking simulations of the a decarboxylative condensation of malonyl-CoA with the enzyme-bound 4-hydroxyphenylpropionyl unit, b formation of the 4-hydroxyphenylpropionyl-β-diketide-CoA intermediate, and c decarboxylative condensation of phenylpropionyl-β-diketide acid nonenzymatically derived from phenylpropionyl-β-diketide-CoA with the enzyme-bound benzoyl unit. d Schematic representation of the proposed mechanism for the formation of 5-(4-hydroxyphenyl)-1-phenylpentane-1,3-dione by PECPS. The entrances to the catalytic cavities are indicated with red arrows

Biosynthetic pathway of PECs

PECs are structurally classified into three types: FDC-type, OAC-type, and ATC-type, and the OAC-type has been proposed to be the biosynthetic precursor of the FDC- and ATC-types [52]. However, the present study clearly showed that the FDC-type is biosynthesized after the production of the diarylpentanoid by PECPS, although we did not identify any other enzymes involved in the biosynthesis after PECPS. Fortunately, biosynthetic pathways of compounds can often be predicted using substrate analogs. To this end, we also performed experiments feeding the non-physiological substrate, 5-(4-fluorophenylethyl)-1-phenylpentane-1,3-dione, to the A. sinensis calli. The feeding experiment revealed that the A. sinensis calli produced the FDC-type, 2-(4-fluorophenylethyl)-4H-chromen-4-one, together with its partially epoxidized compound 14 (Fig. 8). Furthermore, the stability test of oxidoagalochromone C in a methanol aqueous solution indicated that it was easily converted to compound 15 (structural analog of 14) and compound 16 (all epoxy rings-cleaved OAC-type PEC) (Fig. 8). These findings suggested that among all three types, the FDC-type PECs are first biosynthesized from the linear diarylpentanoids via the hydroxylation and subsequent O-methylation(s) of the hydroxy group(s), and the OAC-type PECs are formed via the epoxidation of FDA-type PECs. Finally, the ATC-type PECs might be biosynthesized from OAC-type PECs by a ring‐opening reaction.

Conclusion

The number of original agarwood plants has been drastically reduced due to excessive harvesting. Our research revealed the key enzyme in the biosynthesis of the agarwood fragrance components, PECs. Although the results are not immediately applicable to the cultivation of artificial agarwood, the discovery of PECPS as the key biosynthetic enzyme that forms the common intermediate of the PECs might facilitate explorations of different cultivation conditions by monitoring its gene expression. Although further identification of the downstream enzymes responsible for the biosynthesis of PECs after PECPS is also necessary, this foundational work on PECPS can be expanded to further create PECs analogs by incorporating the pecps gene into other species. This study thus provides insights into not only the cultivation of artificial agarwood, but also the conservation of original agarwood plants.

References

Rasool S, Mohamed R (2016) Agarwood. ed. Mohamed R. Springer, Singapore, pp 39–56

Liu Y-Y, Wei J-H, Gao Z-H, Zhang Z, Lyu J-C (2017) A review of quality assessment and grading for agarwood. Chin Herb Med 9:22–30

López-Sampson A, Page T (2018) History of use and trade of agarwood. Econ Bot 72:107–129

Tan SC, Isa NM, Ismail I, Zainal Z (2019) Agarwood introduction: current development and future perspectives. Front Plant Sci 10:122

Chen H-Q, Wei J-H, Yang J-S, Zhang Z, Yang Y, Gao Z-H, Sui C, Gong B (2012) Chemical constituents of agarwood originating from the endemic genus Aquilaria plants. Chem Biodivers 9:236–250

Wang S, Zhangxin YuZ, Wang C, Wu C, Guo P, Wei J (2018) Chemical constituents and pharmacological activity of agarwood and Aquilaria plants. Molecules 23:342

Gao M, Han X, Sun Y, Chen H, Yang Y, Liu Y, Meng H, Gao Z, Xu Y, Zhang Z, Han J (2019) Overview of sesquiterpenes and chromones of agarwood originating from four main species of the genus Aquilaria. RSC Adv 9:4113–4130

Li W, Chen H-Q, Wang H, Mei W-L, Dai H-F (2021) Natural products in agarwood and Aquilaria plants: chemistry, biological activities and biosynthesis. Nat Prod Rep 38:528–565

Chen D, Xu Z, Chai X, Zeng K, Jia Y, Bi D, Ma Z, Tu P (2012) Nine 2-(2-phenylethyl)chromone derivatives from resinous wood of Aquilaria sinensis and their inhibition of LPS-induced NO production in RAW264.7 cells. Eur J Org Chem 5389–5397.

Ibrahim SRM, Mohamed GA (2015) Natural occurring 2-(2-phenylethyl) chromones, structure elucidation and biological activities. Nat Prod Res 29:1489–1520

Huo H-X, Gu Y-F, Sun H, Zhang Y-F, Liu W-J, Zhu Z-X, Shi S-P, Song Y-L, Jin H-W, Zhao Y-F, Tu P-F, Li J (2017) Anti-inflammatory 2-(2-phenylethyl)chromone derivatives from Chinese agarwood. Fitoterapia 118:49–55

Huo H-X, Zhu Z-X, Song Y-L, Shi S-P, Sun J, Sun H, Zhao Y-FZ, Zheng J, Ferreira D, Zjawiony JK, Tu P-F, Li J (2018) Anti-inflammatory dimeric 2-(2-phenylethyl)chromones from the resinous wood of Aquilaria sinensis. J Nat Prod 81:543–553

Iwagoe K, Konishi T, Kiyosawa S, Shimada Y, Miyahara K, Kawasaki T (1986) The structures of AH10 and AH11, novel biphenylethylchromones from agalwood. Chem Pharm Bull 34:4889–4891

Yang Y, Mei W-L, Kong F-D, Chen H-Q, Li W, Chen Z-B, Dai H-F (2017) Four new bi-2-(2-phenylethyl)chromone derivatives of agarwood from Aquilaria crassna. Fitoterapia 119:20–25

Huo H-X, Gu Y-F, Zhu Z-X, Zhang Y-F, Chen X-N, Guan P-W, Shi S-P, Song Y-L, Zhao Y-F, Tu P-F, Li J (2019) LC–MS–guided isolation of anti-inflammatory 2-(2-phenylethyl)chromone dimers from Chinese agarwood (Aquilaria sinensis). Phytochemistry 158:46–55

Li W, Yang Y, Dong W, Wang H, Kong F, Cai C, Mei W, Dai H (2019) Dimeric 2-(2-phenylethyl)chromones from the agarwood of Aquilaria crassna in Laos. Fitoterapia 133:12–16

Iwagoe K, Kodama S, Konishi T, Kiyosawa S, Fujiwara Y, Shimada Y (1987) The structures of AH15 and AH18, new bi- and triphenylethylchromones from agalwood. Chem Pharm Bull 35:4680–4682

Konishi T, Iwagoe K, Kiyosawa S, Fujiwara Y (1989) Tri-2-(2-phenylethyl) chromones from agalwood. Phytochemistry 28:3548–3550

Konishi T, Iwagoe K, Sugimoto A, Kiyosawa S, Fujiwara Y, Shimada Y (1991) Studies on agalwood (Jinkō). X. Structures of 2-(2-Phenylethyl)chromone derivatives. Chem Pharm Bull 39:207–209

Shao H, Kong F-D, Wang H, Mei W-L, Dai H-F (2017) Qinanmer, a new compound from Chinese agarwood ‘Qi-Nan’ originating from Aquilaria sinensis. J Asian Nat Prod Res 19:935–940

Yang Y, Chen H-Q, Kong F-D, Zhou L-M, Li W, Dong W-H, Chen Z-B, Mei W-L, Dai H-F (2018) Dimeric sesquiterpenoid-4H-chromone derivatives from agarwood of Aquilaria crassna and their cytotoxicity. Phytochemistry 145:207–213

Xia LL, Li W, Wang H, Chen H, Cai C, Yang L, Jiang B, Yang Y, Mei W, Dai H (2019) LC–MS guided identification of dimeric 2-(2-phenylethyl) chromones and sesquiterpene-2-(2-phenylethyl)chromone conjugates from agarwood of Aquilaria crassna and their cytotoxicity. Fitoterapia 138:104349

Yang L, Qiao L, Xie D, Yuan Y, Chen N, Dai J, Guo S (2012) 2-(2-Phenylethyl)chromones from Chinese eaglewood. Phytochemistry 76:92–97

Liao G, Mei W-L, Kong F-D, Li W, Yuan J-Z, Dai H-F (2017) 5,6,7,8-Tetrahydro-2-(2-phenylethyl)chromones from artificial agarwood of Aquilaria sinensis and their inhibitory activity against acetylcholinesterase. Phytochemistry 139:98–108

Wang S-L, Tsai Y-C, Fu S-L, Cheng M-J, Chung M-I, Chen J-J (2018) 2-(2-Phenylethyl)-4H-chromen-4-one derivatives from the resinous wood of Aquilaria sinensis with anti-inflammatory effects in LPS-induced macrophages. Molecules 23:289

Yu Z-X (2019) Anti-inflammatory chromones from agarwood produced via whole-tree agarwood-inducing technique of Aquilaria sinensis. Chin Pharm J 54:1945–1950

Lei ZD, Liu DL, Zhao YM, Gao XX (2018) A new 2-(2-phenylethyl) chromone from Aquilaria sinensis. Chem Nat Compd 54:30–33

Zhu ZX, Gu Y, Zhao Y, Song Y, Li J, Tu P-F (2016) GYF-17, a chloride substituted 2-(2-phenethyl)chromone, suppresses LPS-induced inflammatory mediator production in RAW264.7 cells by inhibiting STAT1/3 and ERK1/2 signalling pathways. Int Immunopharmacol 35:185–192

Guo R, Li J, Gu Y, Li Y, Li S, Gao X, Zhu Z, Tu P-F (2017) GYF-21, an epoxide 2-(2-phenethyl)chromone derivative, suppresses innate and adaptive immunity via inhibiting STAT1/3 and NF-κB signalling pathways. Front Pharmacol 8:281

Williams DA, Zaidi SA, Zhang Y (2014) 5-Hydroxy-2-(2-phenylethyl) chromone (5-HPEC): A novel non-nitrogenous ligand for 5-HT2B receptor. Bioorg Med Chem Lett 24:1489–1492

Williams DA, Zaidi SA, Zhang Y (2015) Synthesis and characterization of 5-hydroxy-2-(2-phenylethyl)chromone (5-HPEC) and its analogues as non-nitrogenous 5-HT2B ligands. J Nat Prod 78:1859–1867

Pojanagaroon S, Kaewrak C (2005) Mechanical methods to stimulate aloes wood formation in Aquilaria crassna Pierre ex H. Lec. (kritsana) trees. Acta Hort 676:89–93

Zhang XL, Liu YY, Wei JH, Yang Y, Zhang Z, Huang JQ, Chen HQ, Liu YJ (2012) Production of high-quality agarwood in Aquilaria sinensis trees via whole-tree agarwood-induction technology. Chin Chem Lett 23:727–730

Liu Y, Chen H, Yang Y, Zhang Z, Wei J, Meng H, Chen W, Feng J, Gan B, Chen X, Gao Z, Huang J, Chen B, Chen H (2013) Whole tree agarwood-inducing technique: an efficient novel technique for producing high-quality agarwood in cultivated Aquilaria sinensis trees. Molecules 18:3086–3106

Li W, Cai C-H, Dong W-H, Guo Z-K, Wang H, Mei W-L, Dai H-F (2014) 2-(2-Phenylethyl)chromone derivatives from Chinese agarwood induced by artificial holing. Fitoterapia 98:117–123

Turjaman M, Hidayat A, Santoso E (2016) Agarwood, ed. Mohamed R, Springer, Singapore, pp 57–71

Wang X-H, Gao B, Liu X, Dong X, Zhang Z, Fan H, Zhang L, Wang J, Shi S-P, Tu P-F (2016) Salinity stress induces the production of 2-(2-phenylethyl) chromones and regulates novel classes of responsive genes involved in signal transduction in Aquilaria sinensis calli. BMC Plant Biol 16:119

Austin MB, Noel JP (2003) The chalcone synthase superfamily of type III polyketide synthases. Nat Prod Rep 20:79–110

Abe I, Morita H (2010) Structure and function of the chalcone synthase superfamily of plant type III polyketide synthases. Nat Prod Rep 27:809–838

Morita H, Abe I, Noguchi H (2010) Plant type III polyketide synthases. In: Liu H-W, Mander L (eds) Comprehensive natural products II: chemistry and biology. Elsevier, Oxford, pp 171–225

Wang X, Zhang Z, Dong X, Feng Y, Liu X, Gao B, Wang J, Zhang L, Wang J, Shi S-P, Tu P-F (2017) Identification and functional characterization of three type III polyketide synthases from Aquilaria sinensis calli. Biochem Biophys Res Comm 486:1040–1047

Wang X, Gao B-W, Nakashima Y, Mori T, Zhang Z-X, Kodama T, Lee Y-E, Zhang Z-K, Wong C-P, Liu Q-Q, Qi B-W, Wang J, Li J, Liu X, Abe I, Morita H, Tu P-F, Shi S-P (2022) Identification of a diarylpentanoid-producing plant polyketide synthase revealing an unusual biosynthetic pathway of 2-(2-phenylethyl)chromones in Agarwood. Nat Commun 13:348

Morita H, Wong CP, Abe I (2019) How structural subtleties lead to molecular diversity for the type III polyketide synthases. J Biol Chem 294:15121–15136

Abe I, Utsumi Y, Oguro S, Morita H, Sano Y, Noguchi H (2005) A plant type III polyketide synthase that produces pentaketide chromone. J Am Chem Soc 127:1362–1363

Morita H, Kondo S, Oguro S, Noguchi H, Sugio S, Abe I, Kohno T (2007) Structural insight into chain-length control and product specificity of pentaketide chromone synthase from Aloe arborescens. Chem Biol 14:359–369

Morita H, Wanibuchi K, Nii H, Kato R, Sugio S, Abe I (2010) Structural basis for the one-pot formation of the diarylheptanoid scaffold by curcuminoid synthase from Oryza sativa. Proc Natl Acad Sci USA 107:19778–19783

Katsuyama Y, Kita T, Funa N, Horinouchi S (2009) Curcuminoid biosynthesis by two type III polyketide synthases in the herb Curcuma longa. J Biol Chem 284:11160–11170

Abe I (2020) Biosynthesis of medicinally important plant metabolites by unusual type III polyketide synthases. J Nat Med 74:639–646

Matsui T, Kodama T, Mori T, Tadakoshi T, Noguchi H, Abe I, Morita H (2017) 2-Alkylquinolone alkaloid biosynthesis in the medicinal plant Evodia rutaecarpa involves collaboration of two novel type III polyketide synthases. J Biol Chem 292:9117–9135

Katsuyama Y, Matsuzawa M, Funa N, Horinouchi S (2007) In vitro synthesis of curcuminoids by type III polyketide synthase from Oryza sativa. J Biol Chem 282:37702–37709

Ferrer JL, Jez JM, Bowman ME, Dixon RA, Noel JP (1999) Structure of chalcone synthase and the molecular basis of plant polyketide biosynthesis. Nat Struct Biol 6:775–784

Yagura T, Shibayama N, Ito M, Kiuchi F, Honda G (2005) Three novel diepoxy tetrahydrochromones from agarwood artificially produced by intentional wounding. Tetrahedron Lett 46:4395–4398

Acknowledgements

Not applicable.

Funding

This work was supported in part by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology, Japan (JSPS KAKENHI Grant 22H02777 to H.M.) and the National Natural Science Foundation of China (Funding ID: 81773842 to S.S.).

Author information

Authors and Affiliations

Contributions

HM, YL, and SS wrote the manuscript and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Morita, H., Lee, YE. & Shi, SP. Identification of a diarylpentanoid-producing polyketide synthase in the biosynthesis of 2-(2-phenylethyl)chromones in agarwood. J Nat Med 77, 667–676 (2023). https://doi.org/10.1007/s11418-023-01743-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11418-023-01743-5