Abstract

Purpose

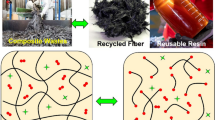

Carbon fibers have been widely used in composite materials, such as carbon fiber-reinforced polymer (CFRP). Therefore, a considerable amount of CFRP waste has been generated. Different recycling technologies have been proposed to treat the CFRP waste and recover carbon fibers for reuse in other applications. This study aims to perform a life cycle assessment (LCA) to evaluate the environmental impacts of recycling carbon fibers from CFRP waste by steam thermolysis, which is a recycling process developed in France.

Methods

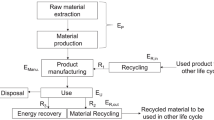

The LCA is performed by comparing a scenario where the CFRP waste is recycled by steam-thermolysis with other where the CFRP waste is directly disposed in landfill and incineration. The functional unit set for this study is 2 kg of composite. The inventory analysis is established for the different phases of the two scenarios considered in the study, such as the manufacturing phase, the recycling phase, and the end-of-life phase. The input and output flows associated with each elementary process are standardized to the functional unit. The life cycle impact assessment (LCIA) is performed using the SimaPro software and the Ecoinvent 3 database by the implementation of the CML-IA baseline LCIA method and the ILCD 2011 midpoint LCIA method.

Results and discussion

Despite that the addition of recycling phase produces non-negligible environmental impacts, the impact assessment shows that, overall, the scenario with recycling is less impactful on the environment than the scenario without recycling. The recycling of CFRP waste reduces between 25 and 30% of the impacts and requires about 25% less energy. The two LCIA methods used, CML-IA baseline and ILCD 2011 midpoint, lead to similar results, allowing the verification of the robustness and reliability of the LCIA results.

Conclusions

The recycling of composite materials with recovery of carbon fibers brings evident advantages from an environmental point of view. Although this study presents some limitations, the LCA conducted allows the evaluation of potential environmental impacts of steam thermolysis recycling process in comparison with a scenario where the composites are directly sent to final disposal. The proposed approach can be scaled up to be used in other life cycle assessments, such as in industrial scales, and furthermore to compare the steam thermolysis to other recycling processes.

Similar content being viewed by others

References

ADEME - Agence de l’Environnement et de la Maîtrise de l’Energie (2012) Déchets – Edition 2012 – Chifres Clés. ADEME, France

ADEME - Agence de l’Environnement et de la Maîtrise de l’Energie (2014) Caractérisation des Déchets. ADEME, France http://www.ademe.fr/expertises/dechets/chiffres-cles-observation/dossier/caracterisation-dechets/resultats. Accessed 03 August 2017

Arena U, Mastellone ML, Perugini F (2003) Life cycle assessment of a plastic packaging recycling system. Int J LCA 8(2):92–98

Baker DA, Rials TG (2013) Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci 130:713–728

Boulanghien M (2014) Formulations de composites thermoplastiques à partir de fibres de carbone recyclées par vapo-thermolyse, Dissertation, University of Toulouse - France

Boulanghien M, Da Silva S, Berthet F, Bernhart G, Soudais Y (2015) Using steam thermolysis to recycle carbon fibres from composite waste. JEC Compos Mag 100:69–70

Devaraj J, Robinson Y, Ganapathi P (2015) Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy 85:304–309

European Commission - Joint Research Centre (2011) International Reference Life Cycle Data System (ILCD) Handbook - recommendations for life cycle impact assessment in the European context, 1st edn. EUR 24571 EN. Publications Office of the European Union, Luxemburg

Georgakellos DA (2002) LCA as a tool for environmental management: a life cycle inventory case study from the greek market. Glob Nest Int J 4:93–106

Griffing E, Overcash M (2010) Carbon fibre HS from PAN. Chemical Life Cycle Database. http://www.environmentalclarity.com. Accessed 11 Aug 2015

Guinee J (2002) Handbook on life cycle assessment operational guide to the ISO standards. Int J LCA 7:311–313

Gustafsson M (2013) Pyrolysis for heat production—biochar the primary byproduct. Master’s Thesis in Energy Systems, University of Gävle

Honus S, Kumagai S, Nemcek O, Yoshioka T (2016) Replacing conventional fuels in USA, Europe, and UK with plastic pyrolysis gases—part I: experiments and graphical interchangeability methods. Energy Convers Manag 126:1118–1127

Howarth J, Mareddy SSR, Mativenga PT (2014) Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J Clean Prod 81:46–50

Industry Experts (2013) Carbon fibers and carbon fiber reinforced plastics (CFRP)—a global market overview. Industry Experts, India

ISO - International Organization for Standardization (1998) ISO 14041: environmental management—life cycle assessment—goal and scope definition and inventory analysis. ISO, Geneva

ISO - International Organization for Standardization (2006) ISO 14040: environmental management—life cycle assessment—principles and framework. ISO, Geneva

Jahn B (2013) Composites Market Report 2013. Carbon Composites e. V. (CCeV), Germany

Kim MH, Song HB (2014) Analysis of the global warming potential for wood waste recycling systems. J Clean Prod 69:199–207

Krutof A, Hawboldt K (2016) Blends of pyrolysis oil, petroleum, and other bio-based fuels: a review. Renew Sust Energ Rev 59:406–419

Li X, Bai R, McKechnie J (2016) Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J Clean Prod 127:451–460

Liu Y, Meng L, Huang Y, Du J (2004) Recycling of carbon/epoxy composites. J Appl Polym Sci 94:1912–1916

Ma Q, Gu Y, Li M, Wang S, Zhang Z (2016) Effects of surface methods treating methods of high-strength carbon fibers on interfacial properties of epoxy resin matrix composite. Appl Surf Sci 379:199–205

Menikpura SNM, Santo A, Hotta Y (2014) Assessing the climate co-benefits from waste electrical and electronic equipment (WEEE) recycling in Japan. J Clean Prod 74:1–8

Morin C, Loppinet-Serani A, Cansell F, Aymonier C (2012) Near and supercritical solvolysis of carbon fibre reinforced polymers (CFRPs) for recycling carbon fibers as a valuable resource: state of the art. J Supercrit Fluids 66:232–240

Nunes AO (2015) Carbon fiber reinforced composites: recovery of carbon fiber by steam-thermolysis, optimization of the process. Dissertation, University of Toulouse - France

Ogi K, Inoue H (2006) Temperature dependence of electrical resistance in carbon fiber and carbon fiber composites. Proceedings of the Twelfth U.S. – Japan Conference on Composite Materials 200–206

Oliveux G, Dandy LO, Leeke GA (2015) Current status of recycling of fibre reinforced polymers: review of technologies, reuse and resulting properties. Prog Mater Sci 72:61–99

ORDIMIP – L’orbservatoire de déchets en Midi Pyrénées. Les fiches déchets. ORDIMIP, France http://www.ordimip.com/dechets?id=100. Accessed 03 Aug 2017

Pickering SJ (2006) Recycling technologies for thermoset composite materials—current status. Compos A Appl Sci Manuf 37:1206–1215

Pimenta S, Pinho ST (2011) Recycling carbon fibre reinforced polymers for structural applications: technology review and market outlook. Waste Manag 31:378–392

Pinçaud M, Aymonier C, Loppinet-Serani A, Perry N, Sonnemann G (2014) Environmental feasibility of the recycling of carbon fibers from CFRPs by solvolysis using supercritical water. ACS Sustain Chem Eng 2:1498–1502

Pinero-Hernanz R, Dodds C, Hyde J, Garcia-Serna J, Poliakoff M, Lester E, Cocero MJ, Kingman S, Pickering S, Wong KH (2008) Chemical recycling of carbon fibre composites in nearcritical and supercritical water. Compos A Appl Sci Manuf 39:454–461

PRé (2016) PRé Consultants. SimaPro Database Manual – Methods Library. Pre –sustainability

Roberts T (2011) The Carbon Fibre Industry Worldwide 2011–2020: an evaluation of current markets and future supply and demand. Mater Tech Pub. ISBN 1 871677 64 5

Society of Environmental Toxicology and Chemistry (SETAC) (1993) Guidelines for life-cycle assessment: a ‘code of practice’. SETAC, Brussels

Song SY, Youn RJ, Gutowski GT (2009) Life cycle energy analysis of fiber-reinforced composites. Compos A Appl Sci Manuf 40:1257–1265

Sun H, Guo G, Menon SA, Xu W, Zhang Q, Zhu J, Xing F (2015) Recycling of carbon fibers from fiber reinforced polymer using electrochemical method. Compos A Appl Sci Manuf 72:61–99

Wang L, Huang R, Zhou B, Zhang Y, Dong Y (2016) Carbon fibers modified with silicone peroxide containing vinyl groups for silicone rubber reinforcement. Mater Lett 176:38–41

Witik RA, Teuscher R, Michaud V, Ludwig C, Manson JAE (2013) Carbon fibre reinforced composite waste: an environmental assessment of recycling, energy recovery and landfilling. Compos A Appl Sci Manuf 49:89–99

Yang Y, Boom R, Irion B, Heerden D-J, Kuiper P, Wit H (2012) Recycling of composites materials. Chem Eng Process Process Intensif 51:53–68

Ye SY, Bounaceur A, Soudais Y, Barna R (2011) Characterisation of carbon fibres reclaimed from steam-thermal treatment. ICCE -19 Annual International Conference on Composites and Nano Engineering. Shanghai, China

Ye SY, Bounaceur A, Soudais Y, Barna R (2013) Parameter optimization of the steam thermolysis: a process to recover carbon fibers from polymer-matrix composites. Waste Biomass Valoriz 4:73–86

Funding

The authors of this paper would like to thank the French Agency for Environment and Energy Management (ADEME) and Alpha Recyclage Composites for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Shabbir Gheewala

Rights and permissions

About this article

Cite this article

Nunes, A.O., Viana, L.R., Guineheuc, PM. et al. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int J Life Cycle Assess 23, 1825–1838 (2018). https://doi.org/10.1007/s11367-017-1416-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1416-6